Method for utilizing sodium alginate to compound nanogold in environment-friendly mode

A technology of sodium alginate and green synthesis, applied in nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve problems such as increasing industrialization costs and limiting the scope of industrialization of nano-gold, and achieves Low industrial cost, easy operation, high repeatability and reproducibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

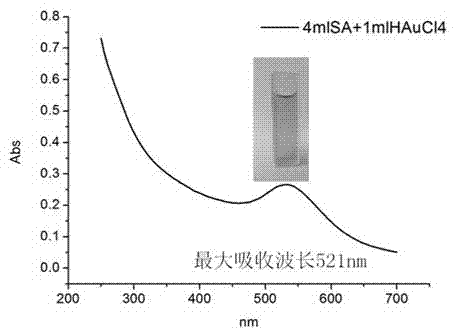

[0022] A kind of method of utilizing sodium alginate green synthesis nano-gold of the present embodiment, its specific steps are as follows:

[0023] 1) Prepare different concentrations of chloroauric acid solution and sodium alginate solution;

[0024] 2) Mix the chloroauric acid solution with the sodium alginate solution, the concentration of chloroauric acid in the mixture is 10 -4 mol / L, the mass percent concentration of sodium alginate is 0.5%, magnetically stirred, and mixed evenly to obtain a reaction precursor solution;

[0025] 3) The reaction precursor solution described in step 2) was placed in a constant temperature water bath at 20°C for 30 minutes to react, and the resulting product was collected. The obtained nano-gold was pink, and the particle size range was between 5 and 20 nm.

Embodiment 2

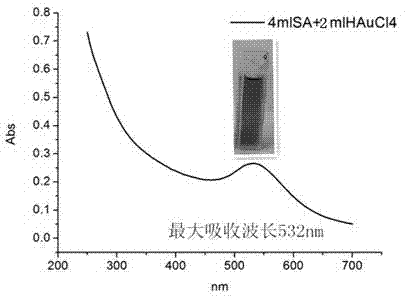

[0027] A kind of method of utilizing sodium alginate green synthesis nano-gold of the present embodiment, its specific steps are as follows:

[0028] 1) Prepare different concentrations of chloroauric acid solution and sodium alginate solution;

[0029] 2) Mix the chloroauric acid solution with the sodium alginate solution, the concentration of chloroauric acid in the mixture is 10 -3 mol / L, the mass percent concentration of sodium alginate is 5%, magnetically stirred, and mixed evenly to obtain a reaction precursor solution;

[0030] 3) The reaction precursor solution described in step 2) was placed in a constant temperature water bath at 60°C for 20 minutes to react, and the resulting product was collected. The obtained nano gold was pink, and the particle size range was between 5 and 20 nm.

Embodiment 3

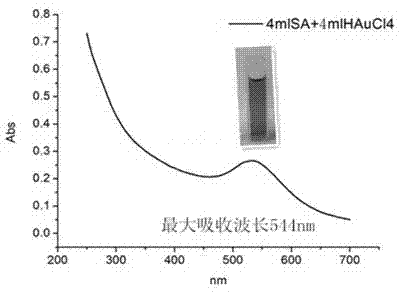

[0032] A kind of method of utilizing sodium alginate green synthesis nano-gold of the present embodiment, its specific steps are as follows:

[0033] 1) Prepare different concentrations of chloroauric acid solution and sodium alginate solution;

[0034] 2) Mix the chloroauric acid solution with the sodium alginate solution, the concentration of chloroauric acid in the mixture is 10 -3 mol / L, the mass percent concentration of sodium alginate is 1%, magnetically stirred, and mixed evenly to obtain a reaction precursor solution;

[0035] 3) The reaction precursor solution described in step 2) was placed in a constant temperature water bath at 60°C for 20 minutes to react, and the resulting product was collected. The obtained nano-gold was purple-red, and the particle size range was distributed between 20 and 60 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com