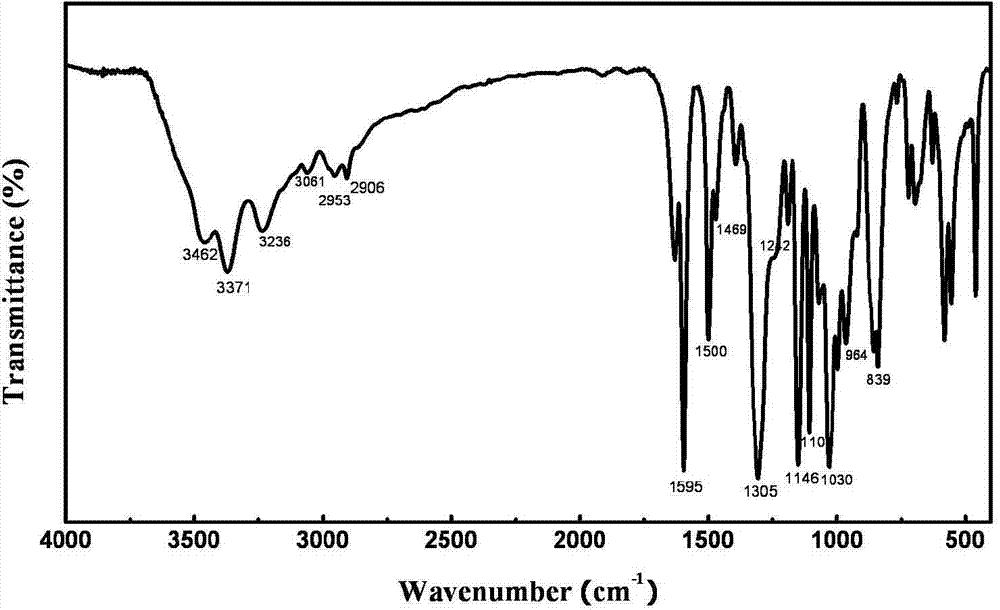

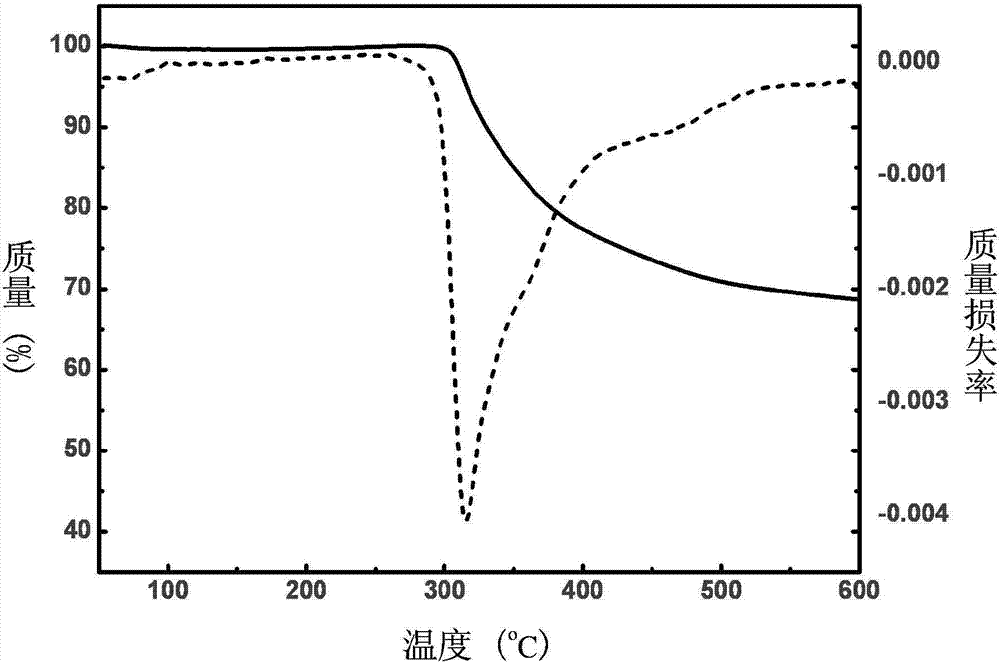

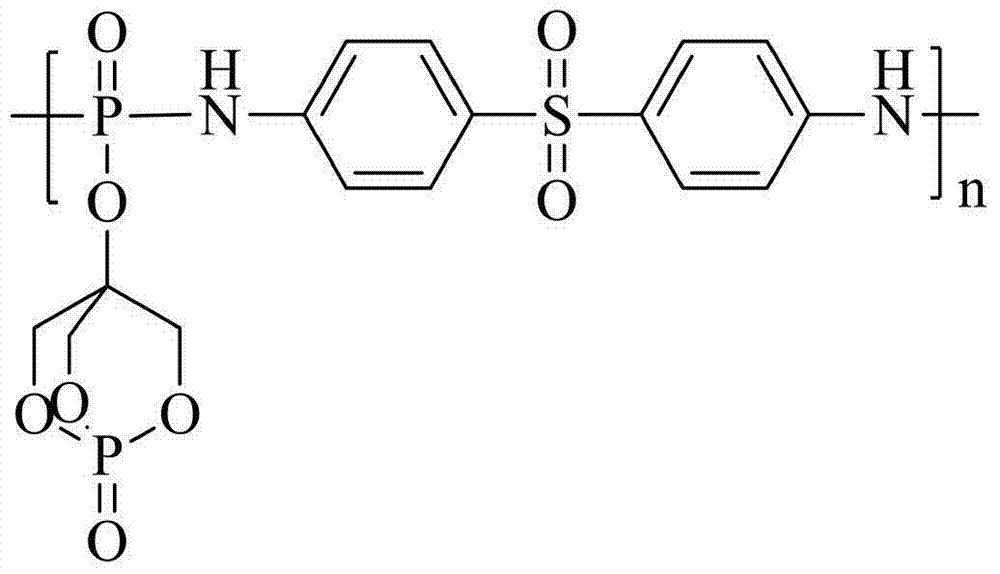

Polyphosphamide fire retardant with bicyclic phosphate structure and preparation method thereof

A technology of bicyclic phosphate and polyphosphoramid, which is applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve the problems of small molecular weight, poor compatibility, easy moisture absorption, etc. Achieve the effect of high carbon formation rate, good thermal stability and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Step 1: Under nitrogen protection, add 3.06g (0.020mol) of phosphorus oxychloride, 3.60g (0.020mol) of PEPA, and 30ml of dioxane into a four-necked flask equipped with a stirrer, reflux condenser, and thermometer. Continue to stir for 30 minutes to disperse PEPA evenly, then raise the temperature to 70°C for 5 hours, cool to room temperature after the reaction, and obtain a solution containing the intermediate PEPA dichlorophosphate;

[0029] Step 2: Add 30 ml of dioxane solution containing 4.96 g (0.020 mol) of 4,4′-diaminodiphenylsulfone and 1.58 g of pyridine (0.020 mol) to the intermediate dichlorophosphate PEPA obtained in step 1 In the ester solution, under stirring conditions, first react at 70°C for 1h, then heat up to 100°C for 8h, cool to room temperature after the reaction, filter to obtain 8.27g of crude product, wash with water, wash with ethanol two-step purification process, after purification After drying at 60°C, 7.07 g of white fluffy powder was obtain...

Embodiment 2

[0035]Step 1: Under nitrogen protection, add 3.82g (0.025mol) of phosphorus oxychloride, 3.60g (0.020mol) of PEPA, 1-methyl-2 - 50ml of pyrrolidone, continue stirring for 30min to disperse PEPA evenly, then raise the temperature to 60°C for 6h, cool to room temperature after the reaction, and obtain a solution containing the intermediate PEPA dichlorophosphate;

[0036] Step 2: Add 50 ml of 1-methyl-2-pyrrolidone solution containing 5.21 g (0.021 mol) of 4,4′-diaminodiphenylsulfone and 2.22 g of triethylamine (0.022 mol) to the intermediate-containing In a solution of PEPA dichlorophosphate, under stirring conditions, first react at 65°C for 2h, then raise the temperature to 120°C for 6h, cool to room temperature after the reaction, filter to obtain 9.27g of crude product, wash with water and wash with acetone for two steps Purification process, drying at 80°C after purification to obtain 7.87g of white fluffy powder, which is a polyphosphoramide flame retardant containing a b...

Embodiment 3

[0038] Step 1: Under nitrogen protection, add 3.37g (0.022mol) of phosphorus oxychloride, 3.60g (0.020mol) of PEPA, and 30ml of acetonitrile into a four-neck flask equipped with a stirrer, reflux condenser, and thermometer, and continue stirring for 30min to disperse PEPA evenly, then raise the temperature to 60°C for 6 hours, and cool to room temperature after the reaction to obtain a solution containing the intermediate PEPA dichlorophosphate;

[0039] Step 2: Add 50 ml of acetonitrile solution containing 6.20 g (0.025 mol) of 4,4′-diaminodiphenylsulfone and 2.53 g of triethylamine (0.025 mol) to the PEPA containing intermediate dichlorophosphate obtained in step 1 In the solution, under stirring conditions, first react at 60°C for 2h, then heat up to 80°C for 12h, cool to room temperature after the reaction, filter to obtain 9.57g of crude product, wash with water, wash with ethanol two-step purification process, after purification 60 ℃ drying to obtain 8.49 g of white fluf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com