Large-area polymer solar cell and method for preparing active layer thereof

A technology for solar cells and polymers, applied in the field of solar cells, can solve the problems of increased additional resistance and reduced photoelectric conversion efficiency of solar cells, and achieves the effects of reducing cell efficiency, ensuring photoelectric conversion efficiency, and increasing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

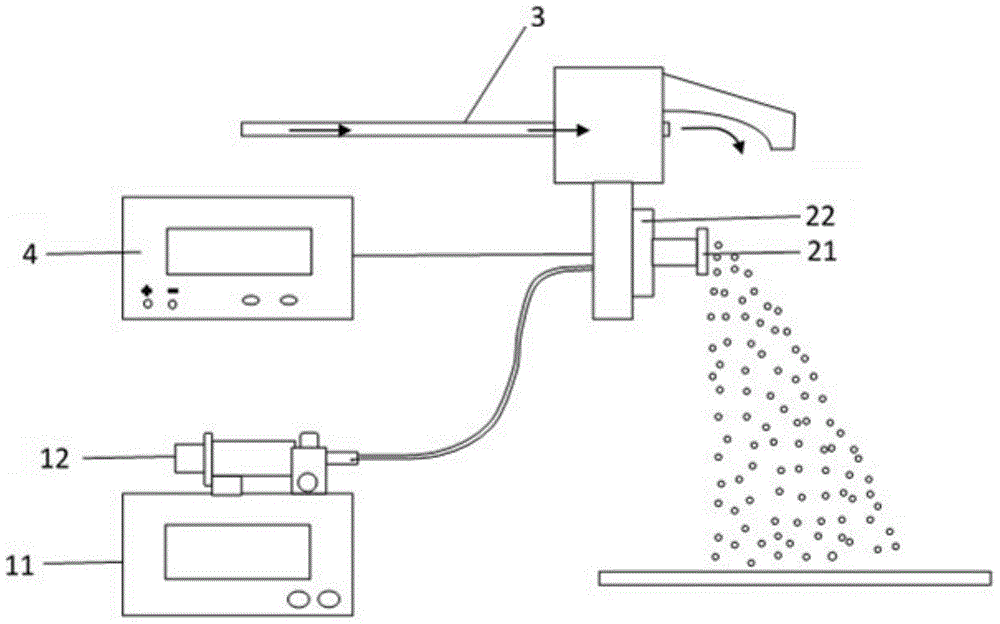

[0032] Combine figure 1 Explain the preparation method of the active layer of large area polymer solar cell, including the following steps:

[0033] (1) Preparation of spray ink containing donor material and acceptor material

[0034] Dissolve the electron donor material and the electron acceptor material in an organic solvent, heat and stir to obtain a uniform mixed solution, and then add additives to the mixed solution and mix uniformly to obtain a spray ink for the active layer;

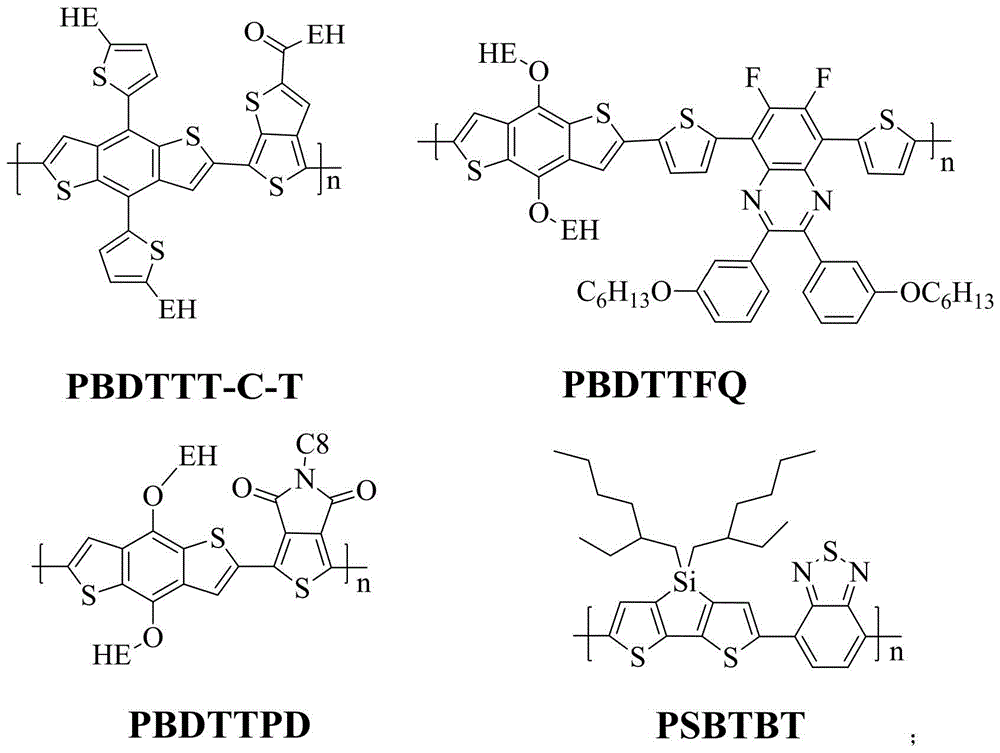

[0035] In step (1), the electron donor material is a conjugated polymer, such as P3HT, PBDTTT-CT, PBDT-TFQ, PBDTPD or PSBTBT, preferably PBDT-TFQ; the electron acceptor material is a fullerene derivative, such as PC 61 BM, PC 71 BM or IC 60 BA, preferably PC 71 BM; the mass ratio of the electron donor material and the electron acceptor material is 4:1-1:4, preferably 1:1; the total mass concentration of the electron donor material and the electron acceptor material in the spray ink is 0.1-60mg / ml, pref...

Embodiment 1

[0070] Preparation of active layer of large area polymer solar cell:

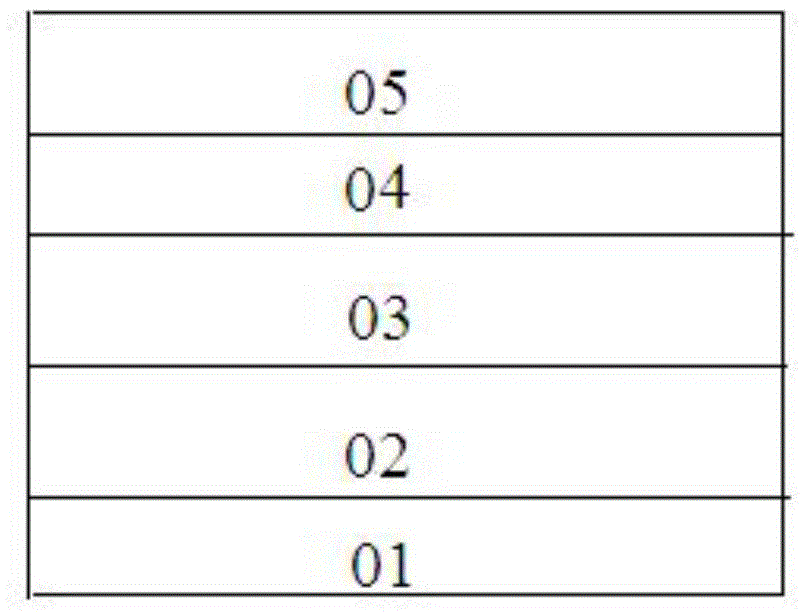

[0071] Combine PBDT-TFQ with PC 71 BM is dissolved in chlorobenzene at a mass ratio of 1:1, heated and stirred to obtain a uniform mixed solution, add 1,8-diiodooctane, and mix uniformly to obtain a spray ink. The spray ink is PBDT-TFQ and PC 71 The total concentration of BM is 4mg / ml, and the volume of 1,8-diiodooctane accounts for 2% of the sprayed ink volume. In an atmospheric environment, spray 5mL of chlorobenzene into the spraying chamber to build an in-situ atmosphere; it is prepared by spraying process 1cm 2 And 10.2cm 2 The active layer, the spraying parameters of the active layer are: the liquid supply speed is 0.35ml / min, the ultrasonic atomizer power is 0.35W, the air flow is 0.4Mpa, the distance between the nozzle and the substrate is 6cm, and the nozzle moving speed is 30mm / s. The number of spraying passes is 2; then it is transferred to the glove box for thermal annealing treatment under the cond...

Embodiment 2

[0074] Preparation of active layer of large area polymer solar cell:

[0075] Connect P3HT with PC 61 BM is dissolved in toluene according to the mass ratio of 1:4, heated and stirred to obtain a uniform mixed solution, added mercaptan, and mixed uniformly to obtain spray ink. P3HT and PC in the spray ink 61 The total concentration of BM is 10mg / ml, and the volume of mercaptan accounts for 10% of the sprayed ink volume. In an atmospheric environment, spray 8mL of carbon disulfide into the spraying chamber to build an in-situ atmosphere; use spraying process to prepare 1cm 2 The active layer, the spraying parameters of the active layer are: the liquid supply speed is 0.5ml / min, the ultrasonic atomizer power is 3.5W, the air flow is 1Mpa, the distance between the nozzle and the substrate is 8cm, the nozzle moving speed is 20mm / s, spraying The number of passes is 5; then it is transferred to the glove box for thermal annealing treatment, and the treatment condition is annealing at 120...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com