Ni3B load carbon composite catalyst for hydrogen production by ammonia borane hydrolysis

A composite catalyst, hydrolysis hydrogen production technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, physical/chemical process catalyst, hydrogen production, etc., can solve problems that have not been reported, and achieve easy implementation and improved utilization efficiency and stability, and the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A kind of carbon-loaded Ni for hydrogen production by ammonia borane hydrolysis 3 The preparation method of B composite catalyst, concrete preparation steps are as follows:

[0019] 1) At room temperature, mix nickel chloride and tetraethylene glycol solution in a round bottom flask and ultrasonically dissolve to obtain a green and transparent mixed solution. The concentration of nickel chloride in the mixed solution is 0.03mol / L. Press Ni in the mixed solution 3 The load of B is 34.25wt%, add the corresponding VulcanXC-72, and ultrasonically stir to form a uniform mixed solution a;

[0020] 2) Mix and dissolve excess potassium borohydride and tetraethylene glycol solution in an ice-water bath to obtain mixed solution b, the concentration of potassium borohydride in mixed solution b is 0.62mol / L;

[0021] 3) Heat the mixed solution a to 45°C in argon, then add the mixed solution b into the mixed solution a, raise the temperature to 280°C under stirring and keep it for ...

Embodiment 2

[0025] A kind of carbon-loaded Ni for hydrogen production by ammonia borane hydrolysis 3 The preparation method of the B composite catalyst, the specific preparation steps are basically the same as in Example 1, the difference is that step 1) press Ni in the mixed solution 3 The loading of B is 50.35wt% and the corresponding VulcanXC-72 is added.

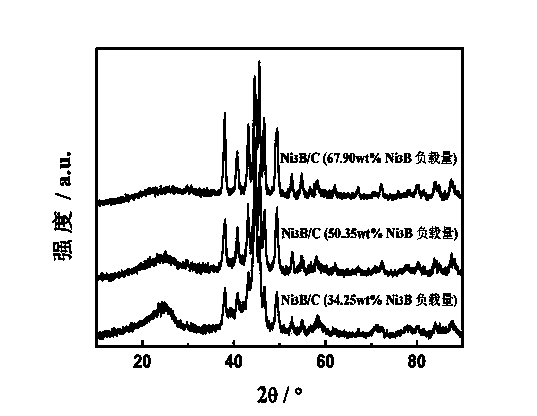

[0026] The carbon supports Ni 3 The XRD pattern of B composite catalyst is as follows figure 1 Shown; TEM picture as image 3 shown.

[0027] Through XRD analysis and elemental analysis, the prepared catalyst is Ni 3 B / C, Ni 3 The B loading was 50.35 wt%.

Embodiment 3

[0029] A kind of carbon-loaded Ni for hydrogen production by ammonia borane hydrolysis 3 The preparation method of the B composite catalyst, the specific preparation steps are basically the same as in Example 1, the difference is that step 1) press Ni in the mixed solution 3 The loading of B is 67.90wt% and the corresponding VulcanXC-72 is added.

[0030] The carbon supports Ni 3 The XRD pattern of B composite catalyst is as follows figure 1 Shown; TEM picture as Figure 4 shown.

[0031] Through XRD analysis and elemental analysis, the prepared catalyst is Ni 3 B / C, Ni 3 The B loading was 67.90 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com