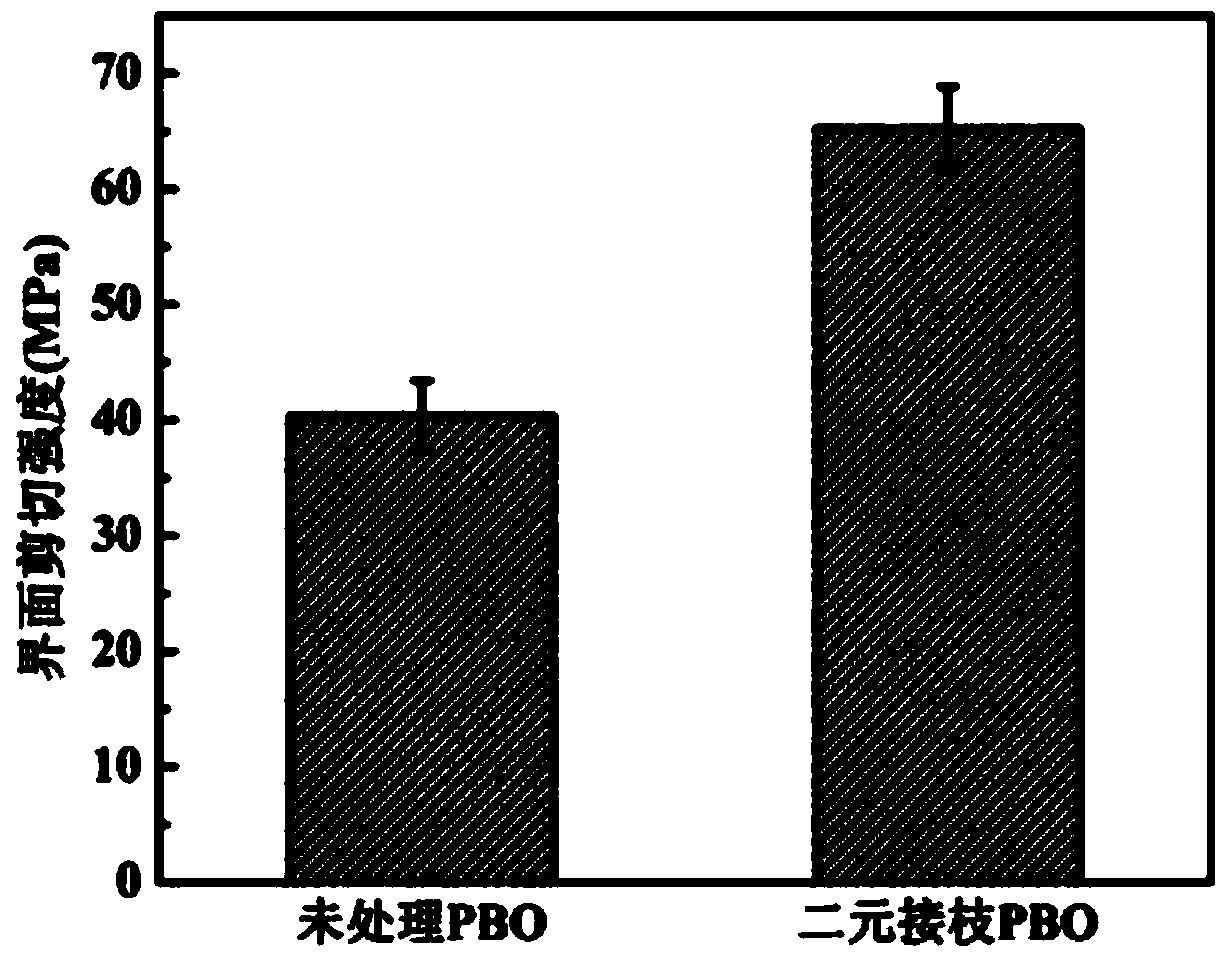

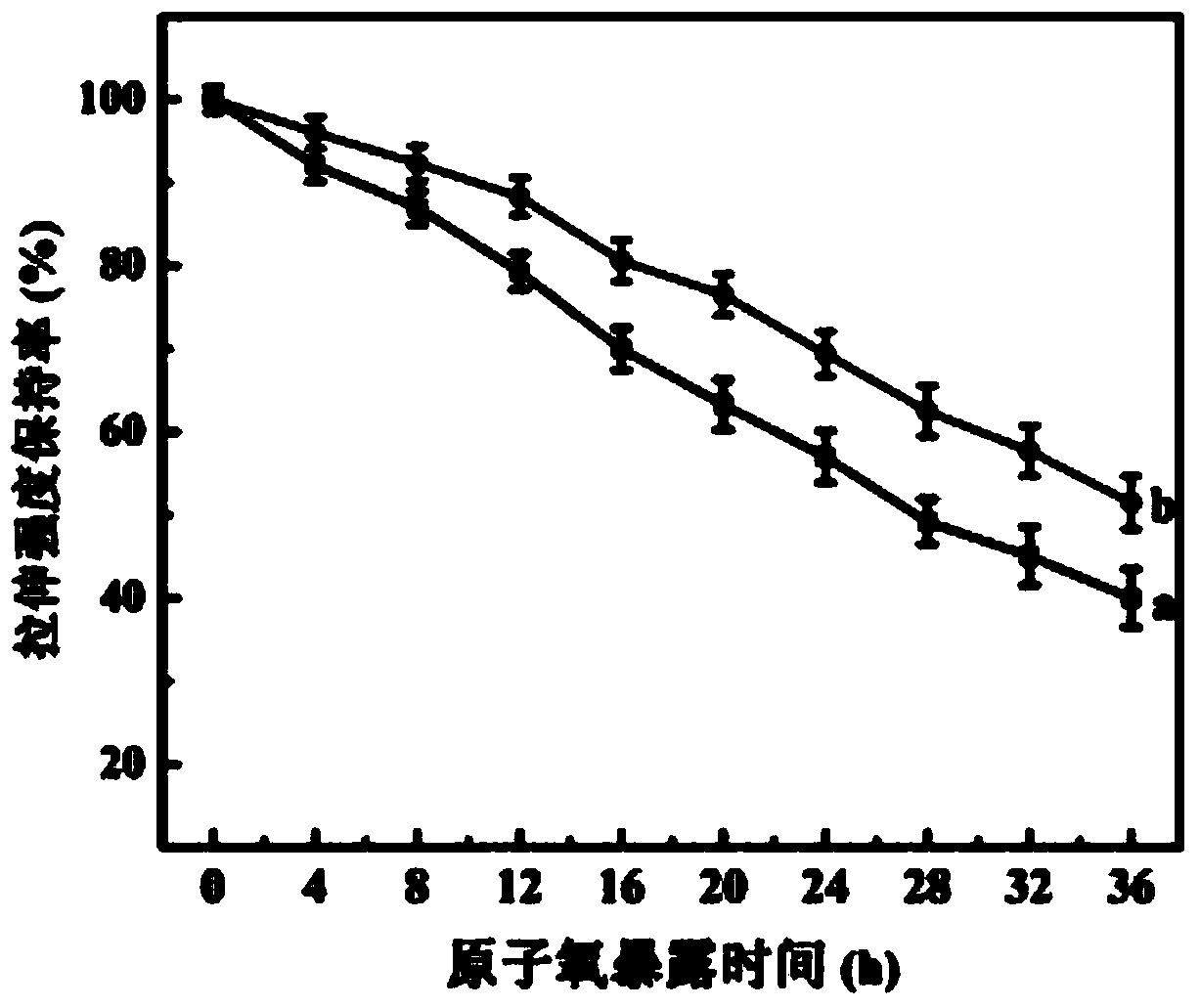

Preparation method for binary grafted modified PBO fiber

A graft modification and fiber technology, which is applied in the field of PBO fiber preparation, can solve the problems of decreased fiber mechanical properties, poor wettability of PBO fibers, molecular chain breakage, etc., and achieves the effect of increasing the contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0020] Specific embodiment one: the preparation method of the binary graft modified PBO fiber of this embodiment is realized according to the following steps:

[0021] 1. Graphene oxide functionalization treatment: Add 10ml~100ml thionyl chloride and 1ml~5ml N,N-dimethylformamide into a single-necked flask, then pour 0.1g~0.4g graphene oxide powder, and Ultrasonic oscillation for 0.5h to 2h, then heating and reflux under nitrogen atmosphere for 12h to 72h, and finally vacuum distillation until the solvent is completely removed to obtain functionalized graphene oxide;

[0022] 2. PBO fiber activation treatment: Wrap the PBO fiber on a square glass frame, immerse it in sulfuric acid solution, stir at room temperature for 1h~4h, take it out and wash it with deionized water for 1~7 times, and finally at 80℃~ Dry at 150°C for 10 minutes to 60 minutes to obtain activated PBO fibers;

[0023] 3. Hydroxyl functionalization treatment of PBO fiber: add 0.02g~0.08g activated PBO fiber t...

specific Embodiment approach 2

[0029] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the vacuum distillation described in step 1 is carried out at a temperature of 40°C to 70°C. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0030] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the mass fraction of the sulfuric acid solution described in step 2 is 20% to 80%. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com