Active graphene composite electrode material

A graphene composite and electrode material technology, applied in hybrid capacitor electrodes, battery electrodes, circuits, etc., can solve the problems of graphene performance advantages that cannot be exerted, easy to agglomerate, etc., and achieves simple preparation process, easy to scale, and multi-diffusion. Effects of Channels and Storage Spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

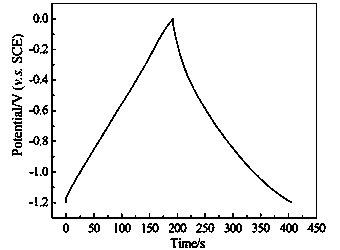

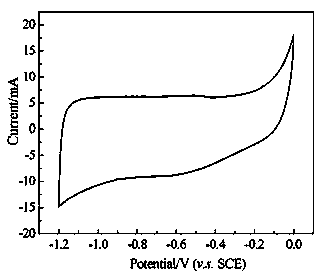

[0024] According to the mass percentage of 30%, the specific surface area is 2200m 2 / g of active graphene and a specific surface area of 1600m 2 / g of activated carbon. Put the activated graphene into the ball mill tank of the ball mill, add a small amount of ethanol and stir for 2 minutes to make the activated graphene completely wet, add activated carbon and continue to stir for 1 hour, take out the mixed material, and dry to obtain the active graphene composite electrode material. Polytetrafluoroethylene is made into pole pieces according to the mass ratio of 95:5, which is used as the electrode of the supercapacitor. Such as figure 1 , 2 shown.

Embodiment 2

[0026] Weigh graphene and rice husk ash as the precursor of activated carbon according to the mass percentage of 60%, mix evenly, infiltrate completely with deionized water, add potassium hydroxide according to the mass ratio of alkali to carbon at 1:3, stir and disperse evenly, and put it into the reaction furnace , the protective gas atmosphere is preactivated at 400°C for 1h, activated at 700°C for 1h, washed with deionized water, and dried to obtain an active graphene composite material, which is made into a pole piece with polytetrafluoroethylene at a mass ratio of 90:10, which can be used as zinc air The electrodes of the battery.

Embodiment 3

[0028]According to the mass percentage of 20%, the specific surface area is 2200m 2 / g of active graphene, put the active graphene into the ball mill tank of the ball mill, add a small amount of ethanol and stir for 3min to make the graphene completely wet, add 2% expanded graphite and stir for 30min, then add a small amount of ethanol and stir for 2min, Add activated carbon and continue stirring for 1 hour, take out the mixed material, and dry to obtain a composite electrode material, which can be used as a fuel cell electrode plate with polyvinylidene fluoride at a mass ratio of 50:50.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com