Polymer solar cell and preparation method thereof

A technology of solar cells and polymers, applied in circuits, photovoltaic power generation, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

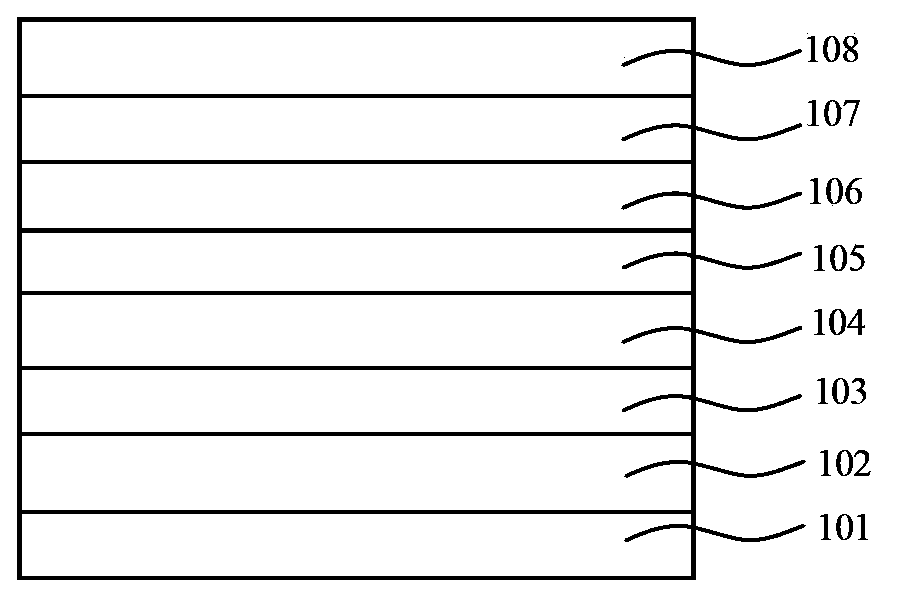

[0074] A method for preparing a polymer solar cell, comprising the steps of:

[0075] (1) Preparation of anode substrate 101: ITO is subjected to photolithography treatment, cut according to the size of 2×2cm, and then ultrasonicated with detergent, deionized water, acetone, ethanol, and isopropanol for 15 minutes to remove organic pollutants on the glass surface ;

[0076] (2) Perform oxygen plasma treatment on the clean ITO, the treatment time is 5~15min, and the power is 10~50W;

[0077] (3) Preparation of the hole buffer layer 102 on the anode substrate: Spin-coat an aqueous solution of poly(3,4-dioxyethylenethiophene) and poly(p-styrenesulfonic acid) with a mass fraction of 4% on the ITO, poly(3,4-dioxyethylene sulfonic acid) The weight ratio of poly(3,4-dioxyethylenethiophene (PEDOT) to poly(p-styrenesulfonic acid) (PSS) in the aqueous solution of oxyethylenethiophene and poly(p-styrenesulfonic acid) is 3:1, spin coating at 4000rpm for 20s , and then heated at 200° C. ...

Embodiment 2

[0087] A method for preparing a polymer solar cell, comprising the steps of:

[0088] (1) Preparation of anode substrate: IZO is subjected to photolithography treatment, cut according to the size of 2×2cm, and then ultrasonicated with detergent, deionized water, acetone, ethanol, and isopropanol for 15 minutes to remove organic pollutants on the glass surface;

[0089] (2) Perform oxygen plasma treatment on the clean IZO, the treatment time is 5~15min, and the power is 10~50W;

[0090] (3) Preparation of a hole buffer layer on the anode substrate: Spin-coat aqueous solutions of poly(3,4-dioxyethylenethiophene) and poly(p-styrenesulfonic acid) with a mass fraction of 5% on IZO, and poly(3,4-dioxyl) The weight ratio of poly-3,4-dioxyethylene thiophene (PEDOT) to poly-p-styrene sulfonic acid (PSS) in ethylene thiophene and poly-p-styrene sulfonic acid aqueous solution is 2:1, spin coating at 6000rpm for 30s, Then heated at 100° C. for 60 min to obtain a hole buffer layer with a ...

Embodiment 3

[0100]A method for preparing a polymer solar cell, comprising the steps of:

[0101] (1) Prepare the anode substrate: perform photolithography on the FTO, cut it according to the size of 2×2cm, and use detergent, deionized water, acetone, ethanol, and isopropanol to sonicate for 15 minutes each to remove organic pollutants on the glass surface;

[0102] (2) UV-ozone treatment of clean FTO;

[0103] (3) Preparation of a hole buffer layer on the anode substrate: Spin-coat an aqueous solution of poly(3,4-dioxyethylenethiophene) and poly(p-styrenesulfonic acid) with a mass fraction of 1% on FTO, and poly(3,4-dioxyl) The weight ratio of poly(3,4-dioxyethylenethiophene (PEDOT) to poly(p-styrenesulfonic acid) (PSS) in the aqueous solution of ethylenethiophene and poly(p-styrenesulfonic acid) was 6:1, spin coating at 2000rpm for 10s, Then heated at 200° C. for 15 minutes to obtain a hole buffer layer with a thickness of 20 nm.

[0104] (4) Prepare the first active layer on the hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com