A kind of visible light catalyzed cross-coupling method to prepare coupling product and release hydrogen

A technology of cross-coupling and visible light, which is applied in the field of cross-coupling hydrogen desorption and visible light catalyzed cross-coupling hydrogen desorption of tertiary amines and nucleophiles. wide range, mild reaction conditions, and efficient cross-coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

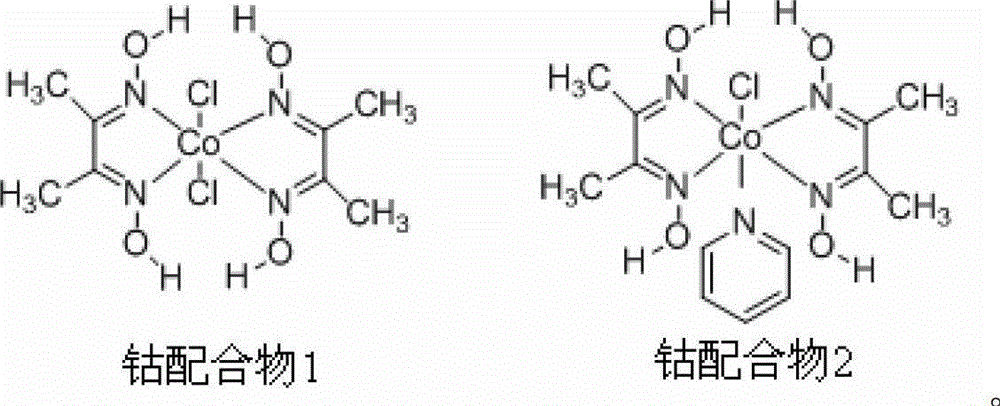

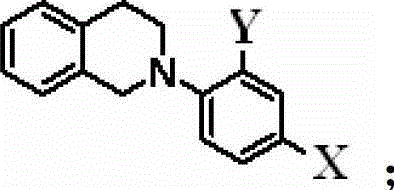

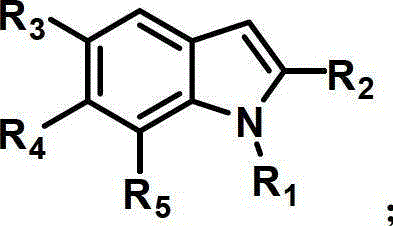

[0032] With cobalt complex 1 as catalyst, 0.36 mg of the catalyst was added to 2 mL of water; with eosinY as photosensitizer, 0.7 mg of the photosensitizer was added to 2 mL of water; the catalyst solution and the photosensitizer solution were mixed to obtain 4 mL of a mixed aqueous solution. Take 0.1mmol tertiary amine-1 (X, Y are H) and 0.2mmol indole-1 (R 1 ﹑ R 2 ﹑ R 3 ﹑ R 4 ﹑ R 5 H) was dissolved in 1 mL of acetonitrile to obtain an acetonitrile solution. Further, 4 mL of the mixed aqueous solution was added to the acetonitrile solution to obtain 5 mL of the mixed solution. Wherein the concentration of photosensitizer is 2.0×10 -4 M, the catalyst concentration is 2.0×10 -4 M. Nitrogen deoxygenated for 30 minutes, sealed with wax, injected with 600 μL of internal standard methane, and then irradiated with 525nm±10nm GreenLEDs at 40°C for 12 hours, using gas chromatography (TCD as the detector, Shanghai Techmei Scientific Instrument Co., Ltd., Techmate 7890II type) )...

Embodiment 2

[0034] With embodiment 1, difference is: add 1.44mg photosensitizer, the concentration of photosensitizer is 4.0 * 10 -4 M. Approximately 315 μL of hydrogen gas was produced. The product is 1-(1H-indol-3-yl)-2-phenyl-1,2,3,4-tetrahydroisoquinoline. The conversion of the starting material was 15%, the yield of the coupling product was 11%, and the amount of hydrogen evolved was 14% relative to the theoretical value.

Embodiment 3

[0036] With embodiment 1, difference is: add 2.04mg photosensitizer, the concentration of photosensitizer is 6.0×10 -4 M. Approximately 427 μL of hydrogen gas was produced. The product is 1-(1H-indol-3-yl)-2-phenyl-1,2,3,4-tetrahydroisoquinoline. The conversion of the starting material was 21%, the yield of the coupling product was 13%, and the amount of hydrogen evolved was 19% relative to the theoretical value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com