Method for preparing fluorine-free super-hydrophobic textile surface

A super-hydrophobic and fabric technology, applied in plant fibers, textiles, papermaking, fiber treatment, etc., can solve problems such as toxicity of fluorine compounds, expensive silane compounds, coating peeling off, etc., to achieve improved wettability, great application value, Effect of improving surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

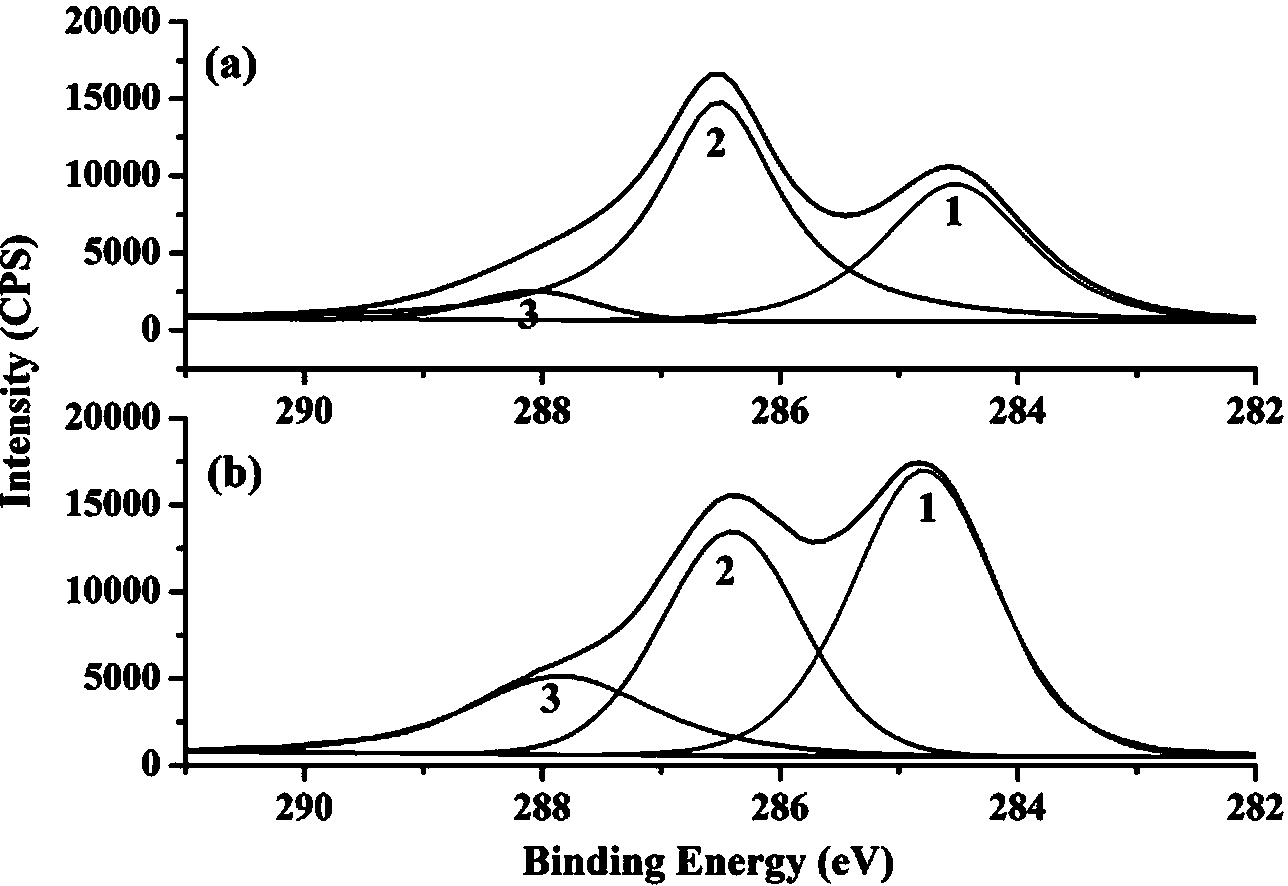

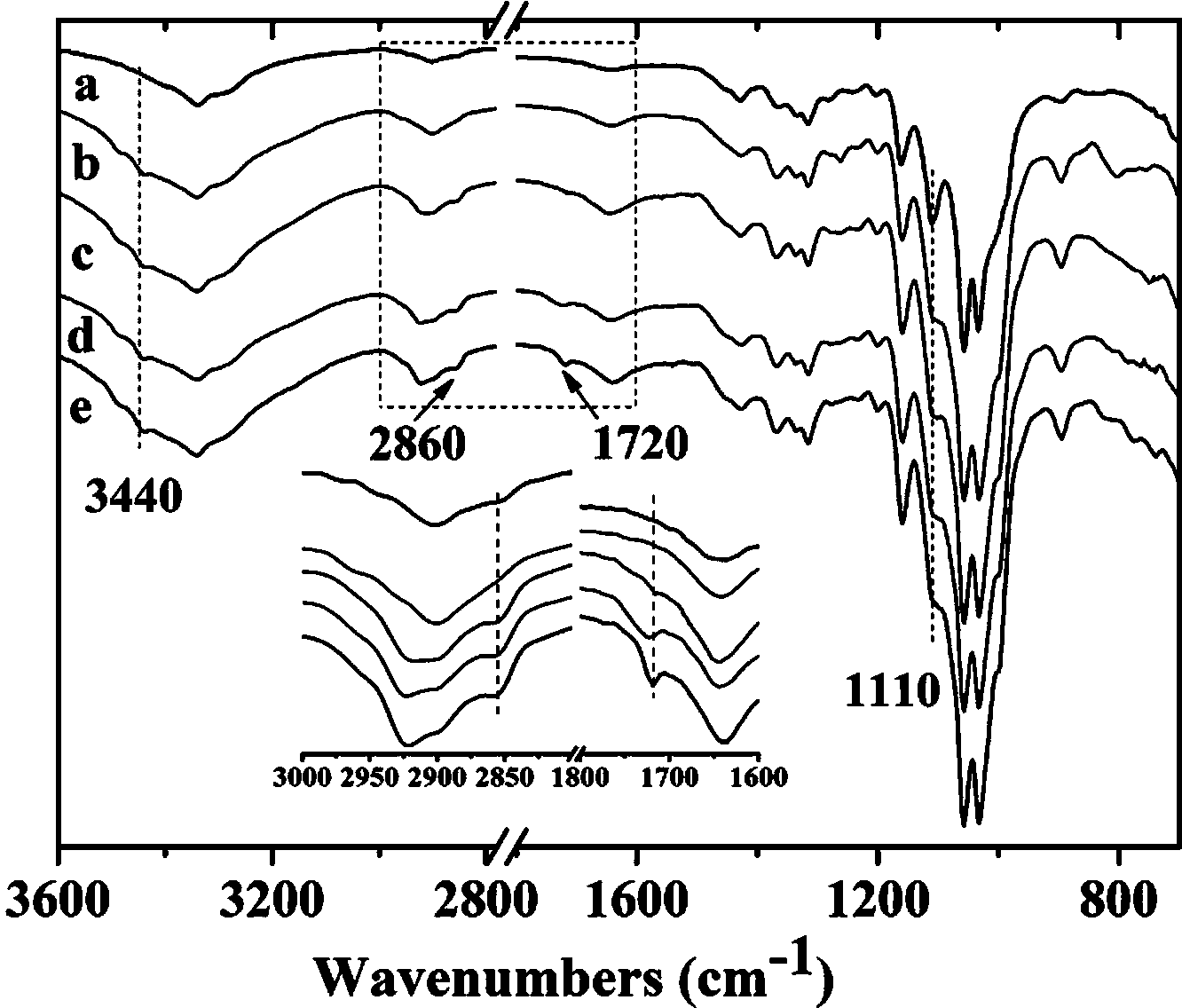

Method used

Image

Examples

Embodiment 1

[0040] a), the first atomization treatment: cut the textile fabric into 1.5 cm x 1.5 cm for use. Weigh cerium ammonium nitrate (ACN) and dissolve in water to prepare 0.8wt% cerium ammonium nitrate (ACN) aqueous solution, get 5 milliliters of cerium ammonium nitrate (ACN) solution and pour it into the atomization cup for atomization treatment, the atomized cerium nitrate The ammonium (ACN) solution is sprayed out in the form of smoke, and the textile fabric is placed about 5 cm from the fog outlet for the first atomization treatment, which ends after about 2 minutes.

[0041] The role of ceric ammonium nitrate (ACN) is an initiator, because ceric ammonium nitrate (ACN) can oxidize groups such as hydroxyl groups into active species, and the active species triggers the polymerization of hydrophobic monomers, so that the polymer layer is directly connected to the cotton fiber matrix, which can No additional monomer was added as a fixative. In order to only generate active species...

Embodiment 2

[0049] a), atomization treatment for the first time: prepare 1.2wt% ceric ammonium nitrate (ACN) aqueous solution;

[0050] b) Preparation of fog polymerization solution: Lauryl methacrylate (LMA) was used as monomer, divinylbenzene was used as crosslinking agent, and octanol was used as solvent to prepare fog polymerization solution. Among them, the concentration of lauryl methacrylate (LMA) is 2.057mol / L, and the molar ratio of divinylbenzene to lauryl methacrylate (LMA) is 1:80~120, so the concentration of divinylbenzene is 17.1417 ~25.7125mmol / L;

[0051] c), atomize the polymerization solution; the range of spray treatment time is 10s~2min.

[0052] d) Initiate precipitation of polymerized droplets: the textile fabric treated with fog is placed in an oven at 80° C. for 10 hours.

[0053] All the other are identical with embodiment 1, obtain the lining with superhydrophobic characteristic on one side.

[0054] Tested by the same analysis method, the results show that la...

Embodiment 3

[0057] a) Prepare fog polymerization solution: use lauryl methacrylate (LMA) as monomer, ethylene glycol dimethacrylate (EGD) as crosslinking agent, and isocyanoethyl methacrylate (ICM) As a fixative, use dibenzoyl peroxide (BPO) as an initiator and ethanol as a solvent to prepare a mist polymerization solution. Among them, the concentration of lauryl methacrylate (LMA) is 0.17mol / L; the molar ratio of ethylene glycol dimethacrylate (EGD) to lauryl methacrylate (LMA) is 1:80~120, so, B The concentration of diol dimethacrylate (EGD) is 1.425~2.1375 mmol / L; isocyanoethyl methacrylate (ICM) is 3.4 mmol / L; the dibenzoyl peroxide (BPO) is 8.0 mmol / L.

[0058] b), atomized mist polymerization solution: take 5 milliliters of mist polymerization solution and put it into the atomization cup for atomization treatment, atomize the mist polymerization solution into tiny droplets with a particle size of 5 microns or less, and the atomized mist polymerization solution It is sprayed out i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com