Building integrated air conditioner

An integrated and architectural technology, applied in buildings, building components, air-conditioning systems, etc., can solve the problems of energy loss in air-water heat exchangers, failure to provide heating in the north, and reduced efficiency, so as to save air-conditioning electricity costs, reduce operating costs, and reduce carbon emissions. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

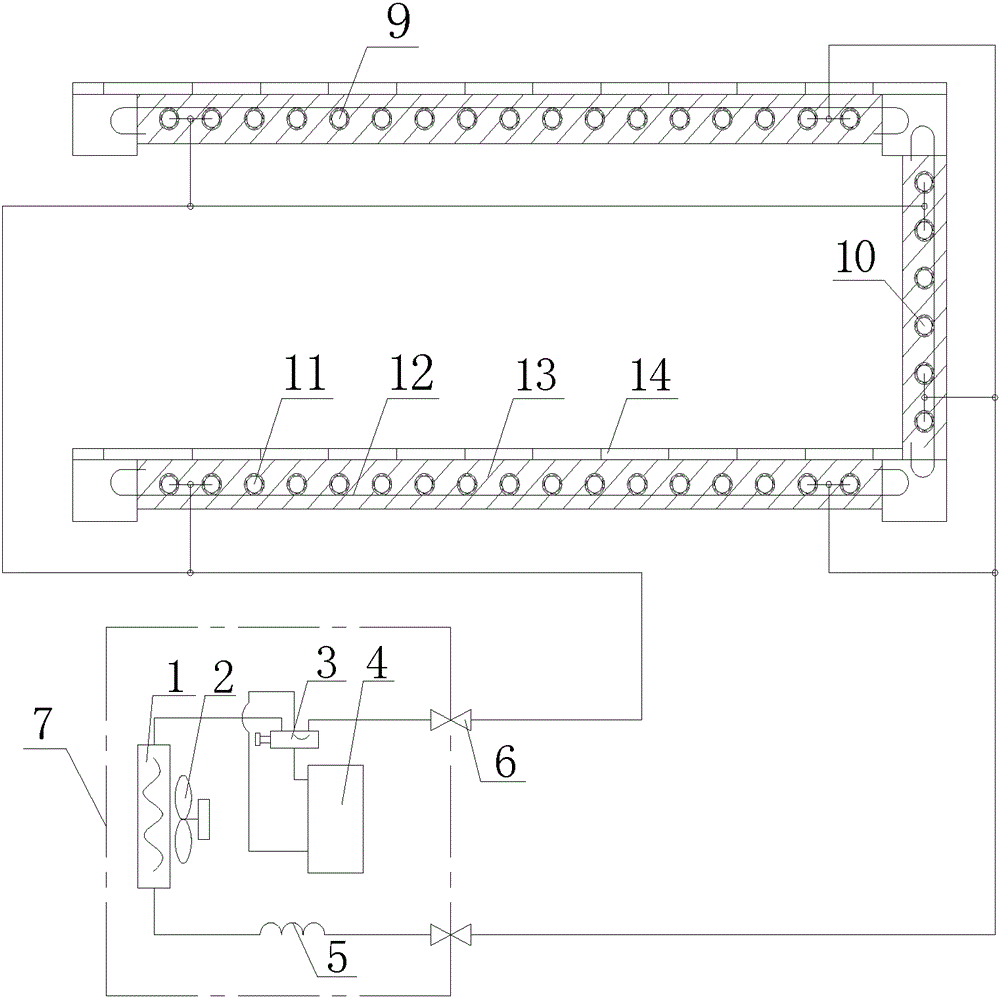

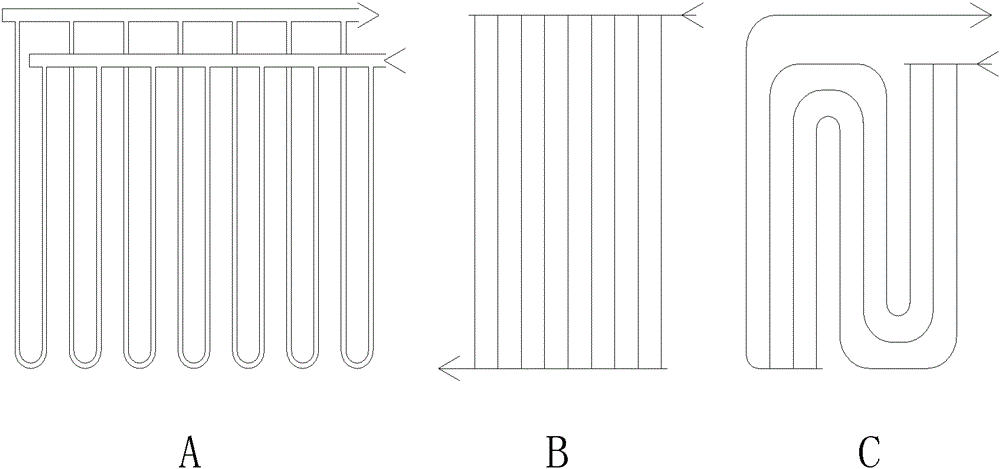

[0046] like figure 1 As shown, in a 16m wide slab building, the wall thickness is 0.6mm, the outer diameter is 2.4mm ceiling microporous pipeline 9, the pressure is 30MPa, the single length is 30m, the distance is 8cm, and the two ends are respectively welded on the guide pipe. Folded to 15m, fixed with clips in the middle to form a pipe network with a pipe distance of 4cm, such as figure 2 -A shown (can also use figure 2 -B, C plane mode), laid on site on the building steel bar 12 and tied up, and cast into one body with cement, 100m 2 A total of 2,500 extended meters are laid on the floor, and the heat exchange surface area is 18.8m 2 , the total flow cross-sectional area: 2cm 2 , Internal volume ratio: 2.8L, using 3.5-10kw carbon dioxide digital frequency conversion outdoor unit; when connecting with R410 refrigerant outdoor unit, the length of a single tube is 5-30m, and the wall thickness is 0.3-0.5mm, which can meet the pressure; The design value of the evaporation...

Embodiment 2

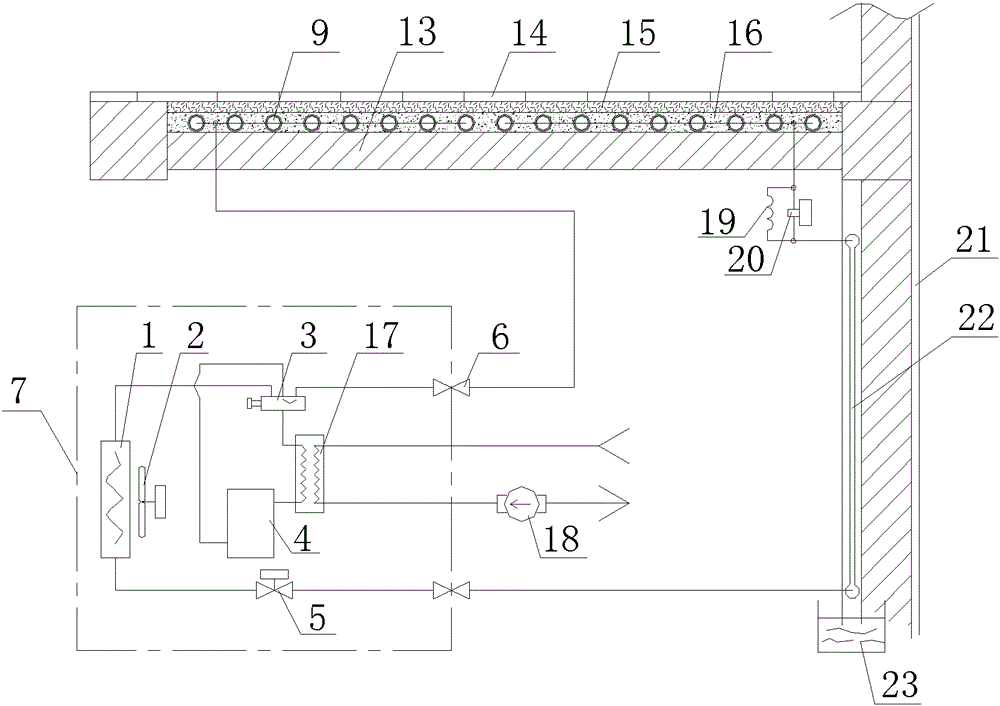

[0054] like image 3 , Figure 4 As shown, PERT or PB microporous tubes are used, the inner hole is 0.5-1 mm, the wall thickness is 1-1.5 mm, and the tube spacing is 2-3 mm. Multiple parallel welding can be pasted on the lower part of the floor 13 with cement glue, or vertically pasted on the wall Body surface, water tank 23 is set below, can also be paved on the ground with cement, sand, graphite.

[0055] Due to the low pressure of this kind of microporous tube, it is more suitable for R22, R134A, R404 and other medium and low pressure refrigerant units to work. During cold storage work in summer, segmental pressure control can be performed, the solenoid valve 20 is closed, and the throttling part 5 is adjusted. Make the cooling evaporation temperature of the pipeline 22 on the surface of the wall between 22-27°C to avoid condensation and keep the indoor temperature constant. The pressure of the return air is equal. Because the floor 13 is thicker, there will be no condens...

Embodiment 3

[0063] like Figure 5 As shown, the carbon conduit fiber cloth 26 is adopted, and the guide pipe 24 is hot-injected with plastics such as PB, PP or PE at both longitudinal ends, and bonded with high-strength heat-conducting adhesive 25 on the ground, ceiling or wall of the completed building. A reinforced adhesive layer is formed to connect the guide pipe 24 to the outdoor unit 7 .

[0064] From the pressure bearing calculation expression ρ=2·wall thickness×(tensile strength / 2) / diameter, it can be seen that the carbon fiber tube with a wall thickness of 30 μm and an inner hole of 20 μm bears a pressure greater than 10 MPa, and the surface area around the fabric tube can be greater than the laying area, while The carbon conduit also has good thermal conductivity. The thickness of the single-layer fabric paving is less than 2mm. Even if there are some accidental damage parts, the high-strength thermal conductive adhesive 25 will seal them. The cross-sectional area of the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com