Diflubenzuron and emamectin benzoate complex agent

A technology of emamectin benzoate and diflubenzuron, applied in the direction of insecticides, biocides, animal repellants, etc., can solve the problems of poor photolysis resistance and easy decomposition, and achieve good effect and low drug cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1: Preparation method: According to the designed formula, add the weighed original medicine, emulsifier, wetting agent, thickener and water into the sand mill cylinder, stir evenly, and disperse under high-speed stirring for 30 minutes, and stop pre-dispersion. Add the sanding medium (glass beads) and defoamer, start the motor, and start sanding. After 2 to 4 hours, stop sanding, filter, remove glass beads, add other additives, antifreeze and stabilizer to mix, to obtain a suspension.

[0037] How to use: Dilute with water at 70 g / 667m2 and spray.

Embodiment 2

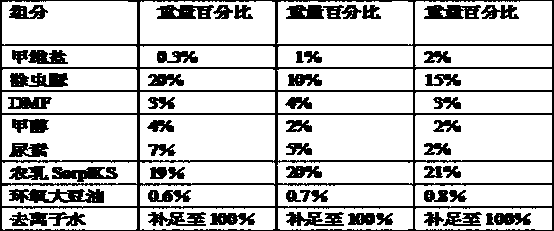

[0038] Example 2: The weight ratio of each component of the microemulsion type compound

[0039]

[0040] Preparation method: phase inversion method. Fully dissolve and mix the original medicine, solvent and emulsifier into a uniform and transparent oil phase. Under stirring, slowly add distilled water or deionized water to form a W / O type emulsion, and then stir and heat to make it rapidly phase inversion O / W type microemulsion is formed, cooled to room temperature, standing and filtered to obtain O / W type microemulsion.

[0041] Usage: Dilute with water at 70 g / 667m2 and spray.

Embodiment 3

[0042] Example 3: The weight ratio of each component of the water dispersible granule type compound agent

[0043] Component weight percentage weight percentage weight percentage

[0044] Emamectin benzoate 0.5% 1% 3%

[0045] Diflubenzuron 30% 20% 15%

[0046] Polyethylene glycol 3% 2% 6%

[0047] Sodium dodecylbenzene sulfonate 6% 5% 9%

[0048] Urea 14% 12% 15%

[0049] Sodium naphthalenesulfonate formaldehyde condensate (NNO) 6% 5% 9%

[0050] White carbon black Make up to 100% Make up to 100% Make up to 100%

[0051] Preparation method: dry method. The original medicine and various additives are mixed uniformly, and then pulverized to the specified fineness by airflow to make a wettable powder. Extrusion granulation. The wettable powder and a certain amount of water (or with a binder) are added to the kneader and kneaded at the same time to form a plastic material with a moisture content of 15-20%. Finally, the material is sent to the extrusion granulator for making Granules are dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com