Pd/C-SiC catalyst for p-phthalic acid hydrorefining, preparation method and application thereof

A technology for terephthalic acid and hydrorefining reactions, which is used in physical/chemical process catalysts, carboxylate preparation, organic compound preparation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] [Example 1] Preparation of C-SiC carrier

[0028] (a) First, put 1.2g a-phase SiC particles (particle size is 2um) into a tube furnace, and program the temperature to 800°C, 900°C, and 1000°C respectively under the He gas atmosphere, and the heating rate is 5°C / min , then pure CCl 4 The liquid is passed through the form of He gas bubbling (that is, He is passed into the CCl-containing 4 After the solvent is removed, the He carrying the chlorine-containing organic solvent is introduced into the reaction system where the SiC particles are located at room temperature), the helium flow rate is 51ml / min, and CCl is continuously introduced into the reaction system. 4 2h, and then switch to a pure He atmosphere to lower the temperature. The prepared material is named C-SiC-T (T is the preparation temperature).

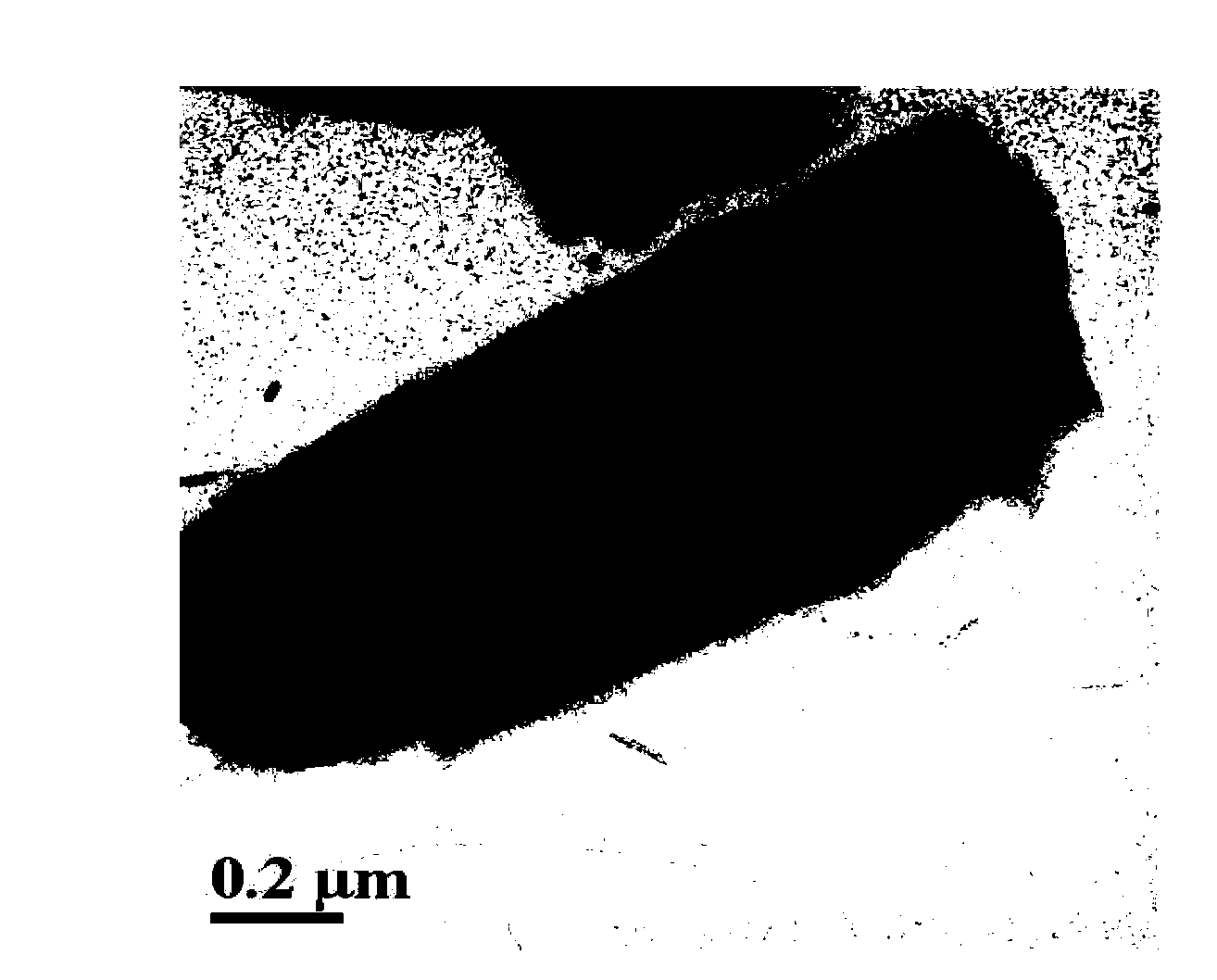

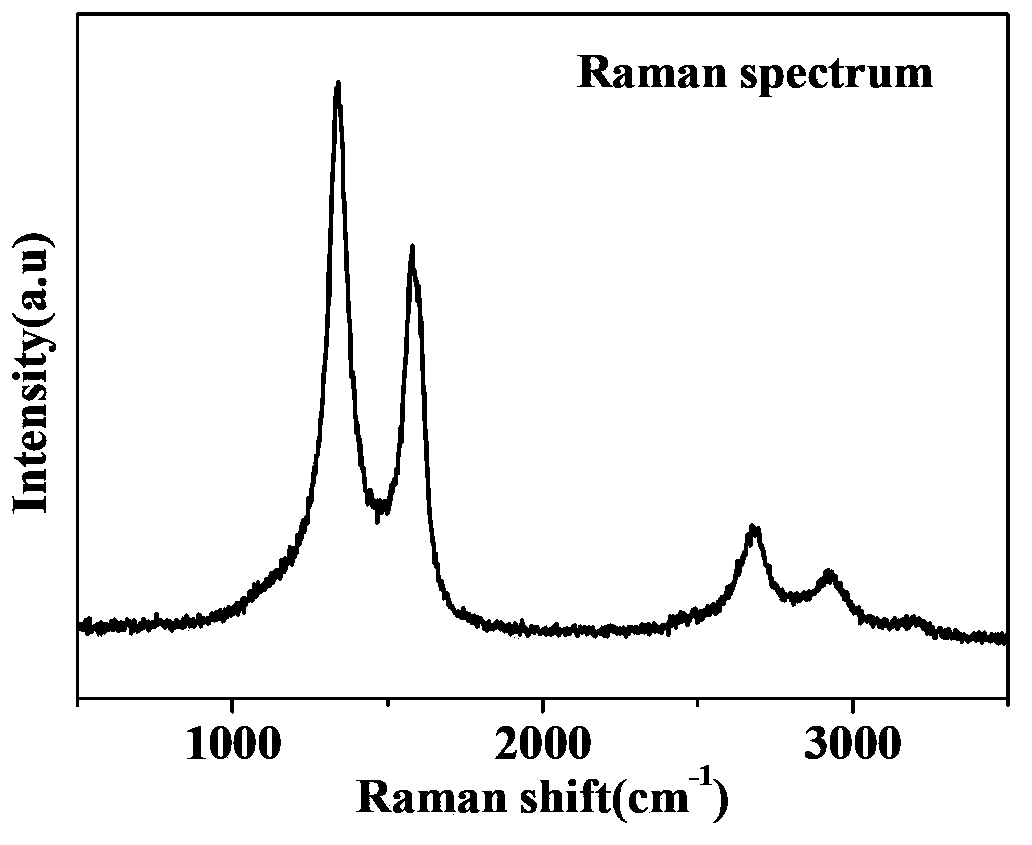

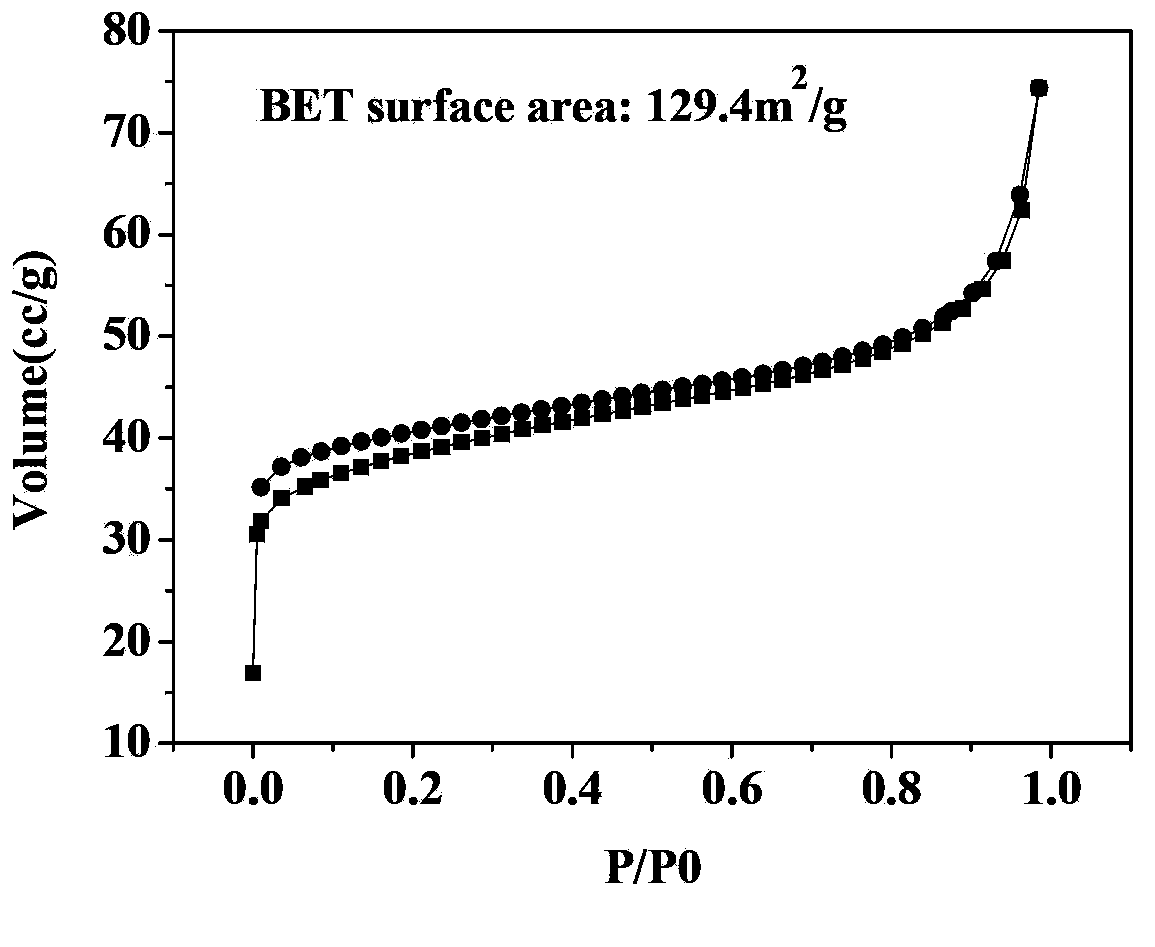

[0029] Such as figure 1 The surface of SiC shown in the electron microscope photo is uniformly covered with carbon layer, figure 2 The Raman spectrum shows the c...

Embodiment 2

[0032] [Example 2] Preparation of Pd / C-SiC catalyst

[0033] (a) The C-SiC carrier of [Example 1] was calcined in air at 400°C for 2 hours.

[0034] (b) Add 0.577g PdCl dropwise to the calcined 0.521g C-SiC carrier with stirring 2 Aqueous solution (Pd mass percentage: 0.457%), stirred until dry, dried overnight at 60°C, reduced with hydrogen at 250°C for 2 hours, to obtain 0.5% Pd / -C-SiC-T (T represents the preparation temperature), And Pd / O-C-SiC-900, Pd / N-C-SiC-800 samples. The comparative Pd / AC (coconut shell carbon) catalyst was prepared as described above using chloropalladium acid as the precursor.

Embodiment 3

[0035] [Example 3] CBA hydrogenation reaction

[0036] Activity evaluation of Pd / C-SiC catalyst for hydrorefining of terephthalic acid was carried out in a batch reactor. 0.200 g of 4-CBA was added to 70 ml of water, and 0.050 g of the Pd / -C-SiC catalyst of [Example 2] was added. 130 DEG C of temperature, hydrogen pressure 0.4MPa, 50 minutes of reaction time, regular sampling, adopt the content of the 4-CBA in the high performance liquid chromatography analysis reaction process, utilize reaction formula ln(C 0 / C i )=kt(C 0 is the concentration of CBA before the reaction, C i is the instant concentration of CBA, k is the kinetic coefficient, and t is the reaction time) in the k value to reflect the catalytic performance of the catalyst. Depend on Figure 5 As shown, the activity of the Pd catalyst supported on C-SiC-900 and C-SiC-1000 is significantly higher than that of the catalyst supported on coconut shell carbon, and the activity of the Pd catalyst supported on C-SiC...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com