Method for preparing antase titanium dioxide nanowire array by virtue of one-step process

A nanowire array, anatase phase technology, applied in the directions of titanium dioxide, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problem of no synthesis, and achieve low cost, simple preparation process, and controllable size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

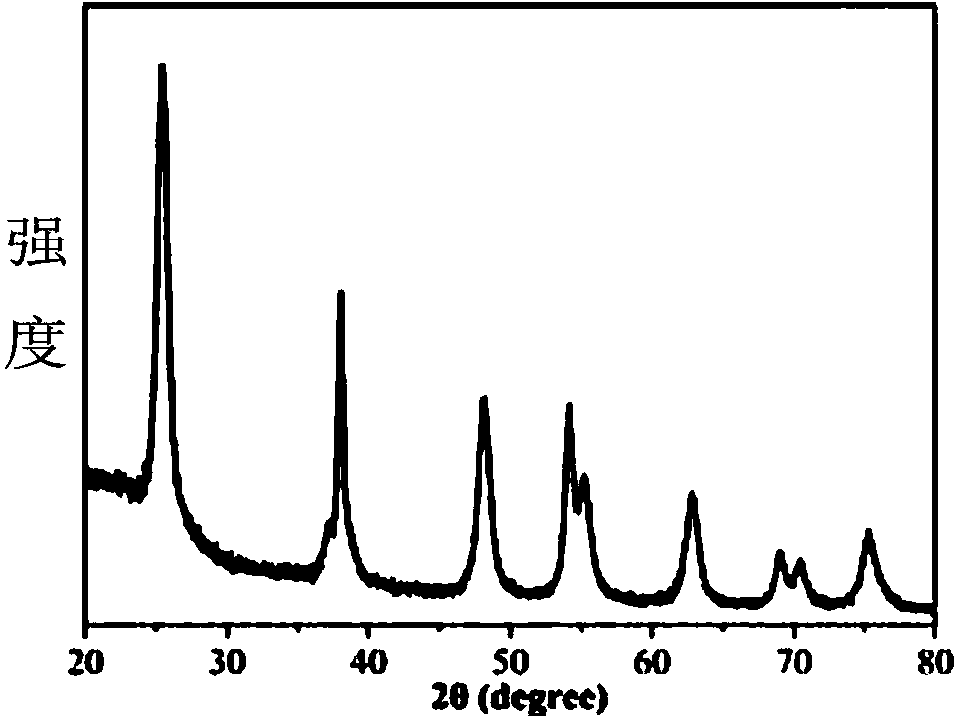

[0020] First, add 1g of crystal face inducer lithium acetate into the beaker, then add 35g of acetic acid, stir ultrasonically, then add 35g of nitrogen nitrogen dimethylacetamide, stir ultrasonically, and finally add 15g of tetrabutyl titanate, mix well Add it into the hydrothermal reaction kettle with the conductive substrate spin-coated with 0.5mol / L tetrabutyl titanate ethanol solution, put it in an oven and react at 160°C for 12h, after the reaction is over, open the reaction kettle and take out the sample , rinse the surface of the sample, and then dry it to obtain a nanowire array, and the length of the nanowire is 500nm. The SEM and XRD patterns of the prepared nanowire arrays are as follows: figure 1 and 2 shown, from figure 1 It can be seen that the nanowires grow uniformly, and the nanowires grow directly on the conductive substrate; from figure 2 It can be seen that this nanowire is an anatase nanowire.

Embodiment 2

[0022] First, add 1g of crystal face inducer sodium acetate into the beaker, then add 35g of acetic acid, stir ultrasonically, then add 35g of nitrogen nitrogen dimethylacetamide, stir ultrasonically, and finally add 15g of tetrabutyl titanate, mix well Add it into the hydrothermal reaction kettle with the conductive substrate spin-coated with 0.5mol / L tetrabutyl titanate ethanol solution, put it in an oven and react at 160°C for 12h, after the reaction is over, open the reaction kettle and take out the sample , rinse the sample surface, and then blow dry. The nanowire length is 2500nm.

Embodiment 3

[0024] First, add 1g of potassium acetate as a crystal face inducer into the beaker, then add 35g of acetic acid, stir ultrasonically, then add 35g of nitrogen nitrogen dimethylacetamide, stir ultrasonically, and finally add 15g of tetrabutyl titanate, mix well Add it into the hydrothermal reaction kettle with the conductive substrate spin-coated with 0.5mol / L tetrabutyl titanate ethanol solution, put it in an oven and react at 160°C for 60h, after the reaction is over, open the reaction kettle and take out the sample , rinse the sample surface, and then blow dry. The nanowire length is 2310nm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com