A silver-titanium composite functional layer low-radiation energy-saving glass and its preparation method

A composite function, energy-saving glass technology, applied in the field of silver-titanium composite functional layer low-emission energy-saving glass and its preparation field, can solve the problems of poor weather resistance, poor corrosion resistance, loss of low-emission energy-saving effect, reduced energy-saving effect, etc., to achieve corrosion resistance. Strong performance, suitable for off-site processing and transportation, and the effect of improving weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

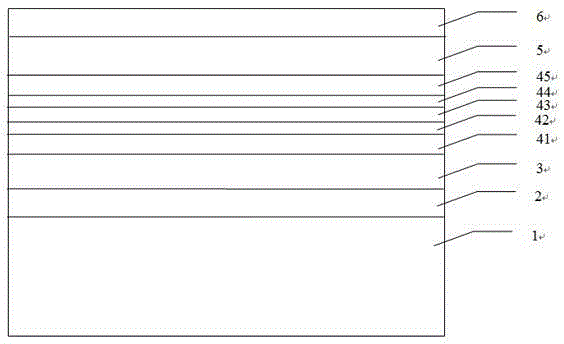

[0027] refer to figure 1 Said, a silver-titanium composite functional layer low-radiation energy-saving glass, the continuous deposition barrier layer sequentially stacked on the coated glass substrate, the first indium tin oxide film layer, silver titanium composite functional layer, the second indium tin oxide film layer ,The protective layer. The barrier layer is used to prevent sodium ions and calcium ions in the glass substrate from entering the functional layer to affect the energy-saving effect. The material of the barrier layer can be silicon oxide or silicon nitride. Silicon oxide or silicon nitride is non-toxic and pollution-free, and is resistant to corrosion and Wear-resistant, the thickness of the layer is 25-35nm; the first indium tin oxide film layer and the second indium tin oxide film layer can effectively reflect infrared rays, cut off part of ultraviolet rays, further improve the energy-saving effect, and the chemical resistance of indium tin oxide film It ...

Embodiment 2

[0031]The invention discloses a method for preparing multifunctional low-radiation energy-saving glass, which adopts manual or automatic coating, and puts the coating surface of the glass substrate in the direction facing the target material into the substrate frame and sends it into the magnetron sputtering equipment. After the glass substrate is sent into the magnetron sputtering chamber, turn on the mechanical pump to evacuate. According to the production cycle requirements, when the vacuum degree reaches the order of 1Pa, start the transmission system and open the isolation valve between the chamber and the buffer chamber. , the substrate rack enters the buffer chamber, open the vacuum to about 0.1Pa, open the isolation valve, enter the process chamber, turn on the vacuum pump to evacuate to 1.0-4Pa, fill in the working gas argon, process gas oxygen or nitrogen (according to Silicon oxide and silicon nitride are different, for the convenience of the front and rear processes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com