Insulating coating, electrical steel material and preparation method of electrical steel material

A technology of insulating paint and electrical steel, applied in metal material coating process, coating, device for coating liquid on the surface, etc., can solve the problems of poor punching and shearing workability and adhesion, and achieve excellent heat resistance, insulation, etc. Excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The present invention also provides a method for preparing an electrical steel material, the method comprising: attaching the above-mentioned insulating coating to the electrical steel substrate, and then curing the insulating coating, and the curing temperature is 150- 250°C.

[0036] According to the preparation method of the electrical steel material of the present invention, the curing temperature is further preferably 180-210°C.

[0037] According to the preparation method of the electrical steel material of the present invention, the amount of the insulating coating may be 5-15 grams, more preferably 7.5-12.5 grams per square meter of the surface of the electrical steel substrate.

[0038] According to the preparation method of the electrical steel material of the present invention, the curing time of the curing may be 10-60s, more preferably 25-40s.

[0039]According to the preparation method of the above electrical steel material provided by the present inventi...

Embodiment 1-18

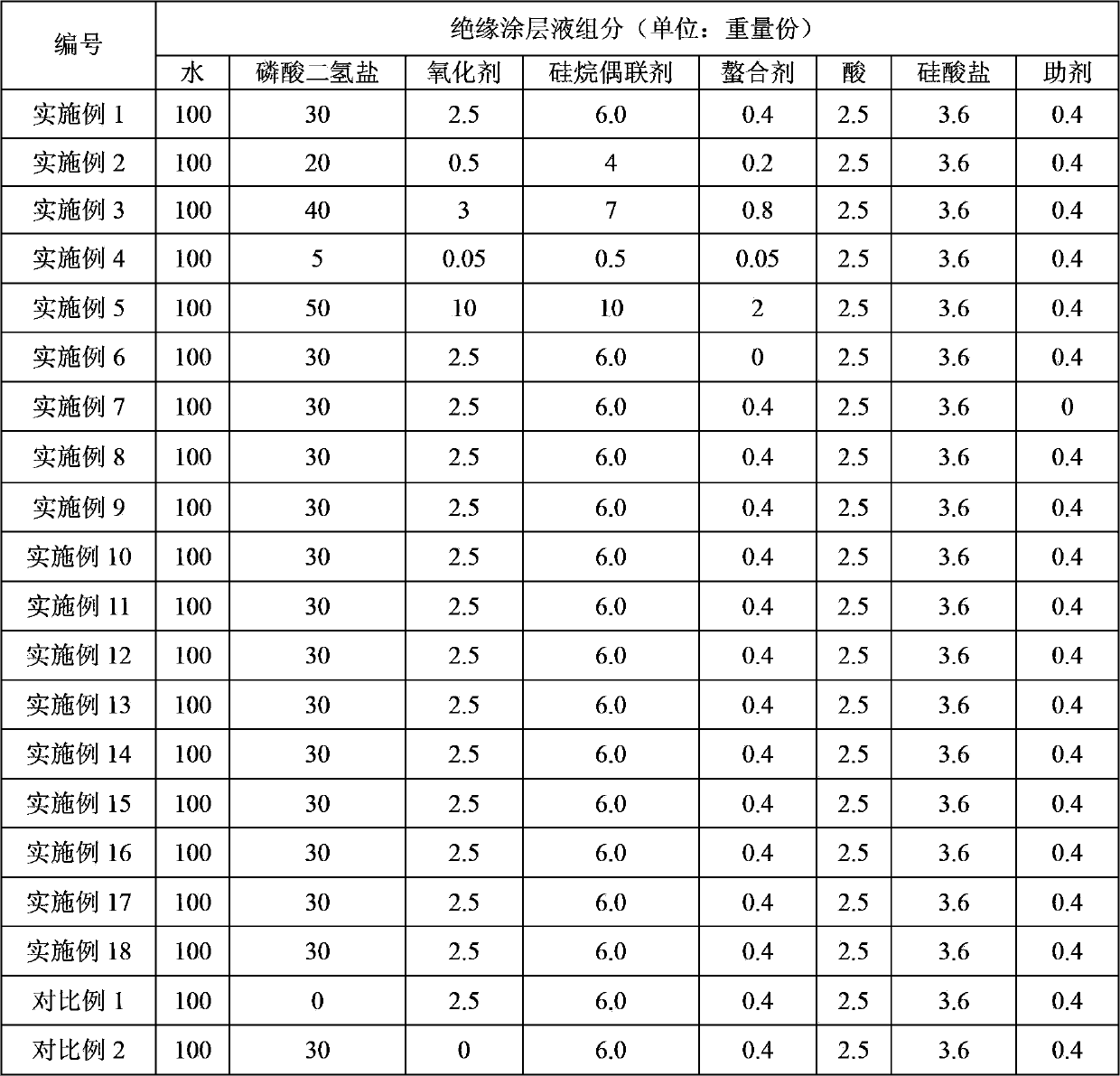

[0046] According to the component contents listed in Table 1, the components were uniformly mixed under stirring conditions to obtain insulating coatings 1-18 respectively.

[0047] Table 1

[0048]

[0049] In embodiment 1-18, the specific selection of each component is as follows:

[0050] Among the embodiment 1-5, the dihydrogen phosphate is manganese dihydrogen phosphate, the oxidant is sodium molybdate, the gamma-aminopropyltriethoxysilane that the silane coupling agent selects, the chelating agent is calcium lignosulfonate, and the acid is Boric acid, the silicate is sodium silicate, relative to 100 parts by weight of water, the content of surfactant in the auxiliary agent is 0.05 parts by weight, the content of leveling agent is 0.10 parts by weight, and the content of defoamer is 0.10 parts by weight parts, the content of the dispersant is 0.15 parts by weight.

Embodiment 6

[0052] The insulating coating was prepared according to the method of Example 1, except that the chelating agent was replaced with water of equal weight to obtain insulating coating 6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com