Process and device for continuously producing glycyrrhetinic acid monoglucuronide by using immobilized cells

A technology of immobilizing cells and glycyrrhetic acid is applied in biochemical cleaning devices, enzymology/microbiology devices, microorganism-based methods, etc., which can solve the problems of complicated separation and purification steps, many impurities in products, and high costs, and achieve Long service life, high product purity and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

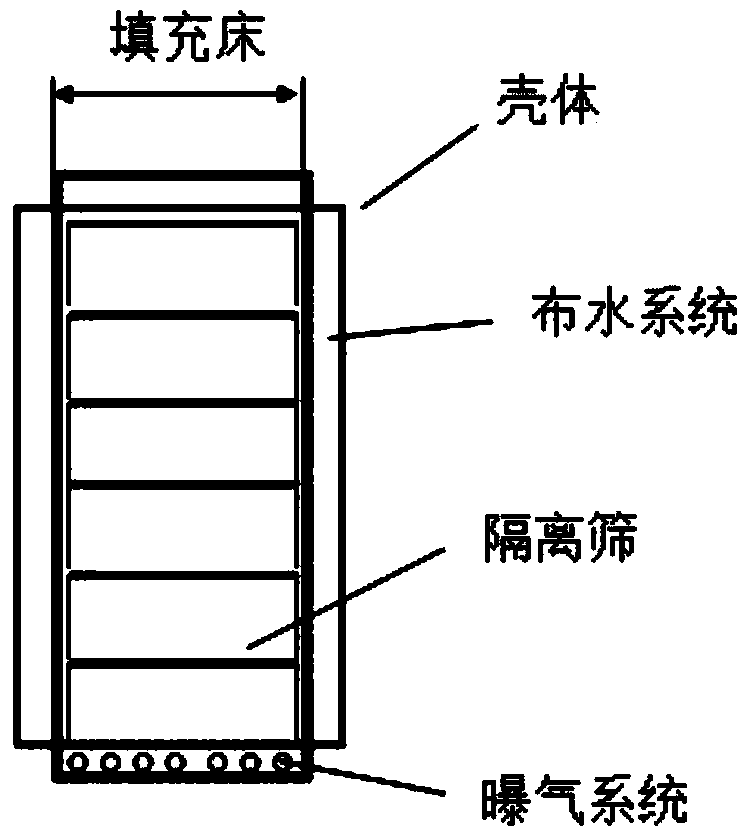

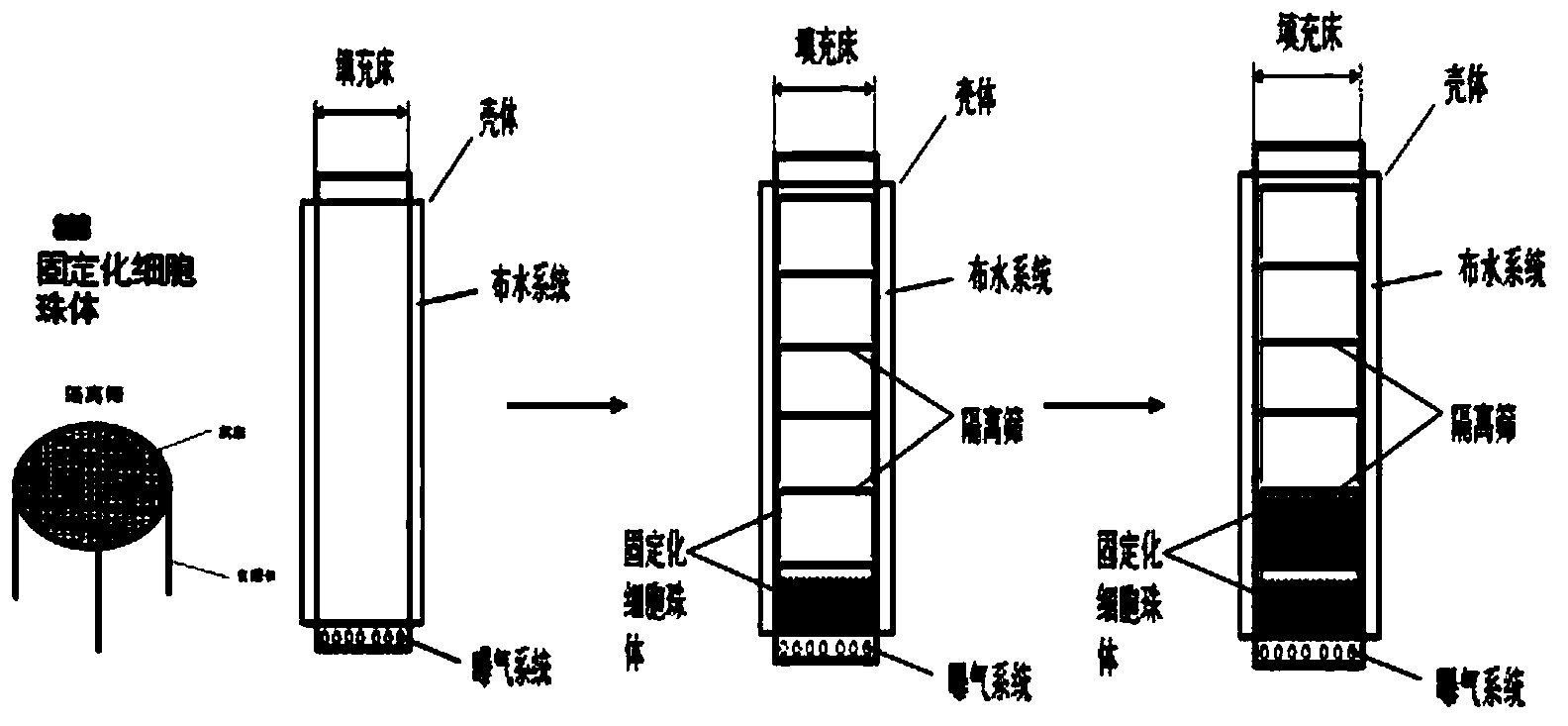

[0024] Fabrication of packed bed reactors

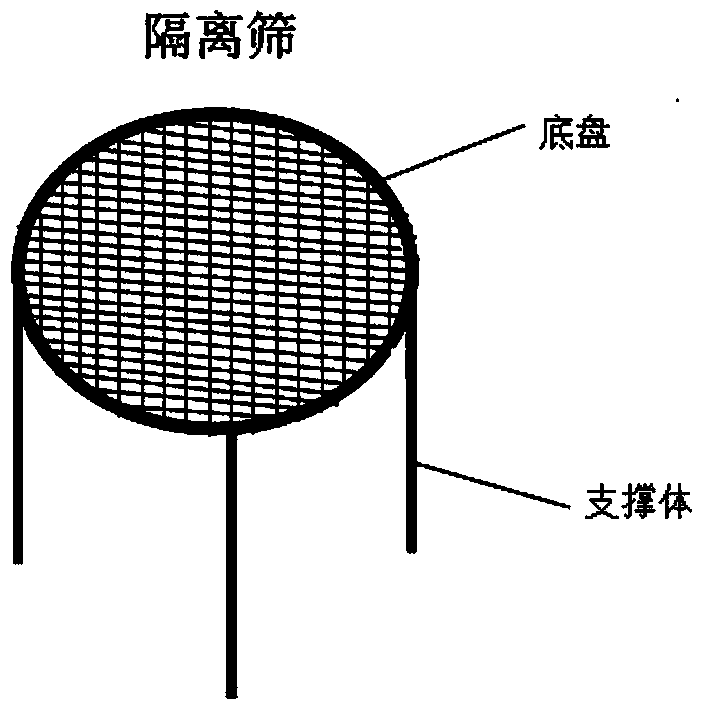

[0025] The packed bed reactor provided in this example is a plexiglass column with an inner diameter of 50 mm, a height of 500 mm, a reactor volume of 981 mL, a diameter of the isolation sieve chassis of 48 mm, and a support column height of 50 mm.

Embodiment 2

[0027] (1) Preparation of Penicillium purpurea Li-3CGMCC NO.5446 cells

[0028] Inoculate the Penicillium purpurea Li-3 cultured on the slant into the seed medium, cultivate at 32°C, 170r / min for 72h, and then transfer to the secondary seed medium at 32°C, 170r / min with an inoculation amount of 1.5% Cultivate for 24 hours to obtain secondary seed liquid. The cultivated secondary seed culture solution was inoculated into a 1000mL Erlenmeyer flask containing 300mL fermentation medium at an inoculum volume of 10% (v / v) for fermentation at a fermentation temperature of 30°C and a rotational speed of 170r / min. The obtained Penicillium purpogenum Li-3 was centrifuged at 12000 rpm for 10 min, and then the thalline was washed 3 times with distilled water.

[0029] The composition of the seed liquid medium is 5.0g glucose and 3.0g NaNO per liter of water 3 , 1.0g K 2 HPO 4 , 0.5gMgSO 4 ·7H 2 O, 0.5g KCl, 0.01g FeSO 4 ·7H 2 O; The composition of the fermenter medium is 4.5g glyc...

Embodiment 3

[0037] (1) The preparation of Penicillium purpogenum Li-3CGMCC NO.5446 cells was the same as described in Example 2.

[0038] (2) Preparation of immobilized Penicillium purpogenum Li-3CGMCC NO.5446

[0039] Add distilled water to prepare 20% bacterial suspension for the fermented bacteria, add 1% diatomaceous earth, stir evenly, and mix with twice the volume of 2.5% sodium alginate solution sterilized at 121°C for 20 minutes. Draw the suspension of sodium alginate bacteria with a syringe, drop into 2% CaCl on a magnetic stirrer running at low speed 2 Immobilize in the solution to form immobilized gel beads of uniform size, the maximum difference in diameter ≤ 0.5mm, immobilize for 12 hours, and prepare gel beads with a diameter of 3mm, and store them in 0.9% physiological saline in a refrigerator at 4°C middle.

[0040] (3) Packing of immobilized cells into a column is the same as described in Example 2.

[0041] (4) Production of monoglucuronyl glycyrrhetinic acid by conti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com