Preparation method of iridium tin metal oxide

A technology of oxides and metals, which is applied in the field of preparation of oxygen evolution electrocatalyst iridium tin oxide, which achieves the effect of less environmental pollution and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

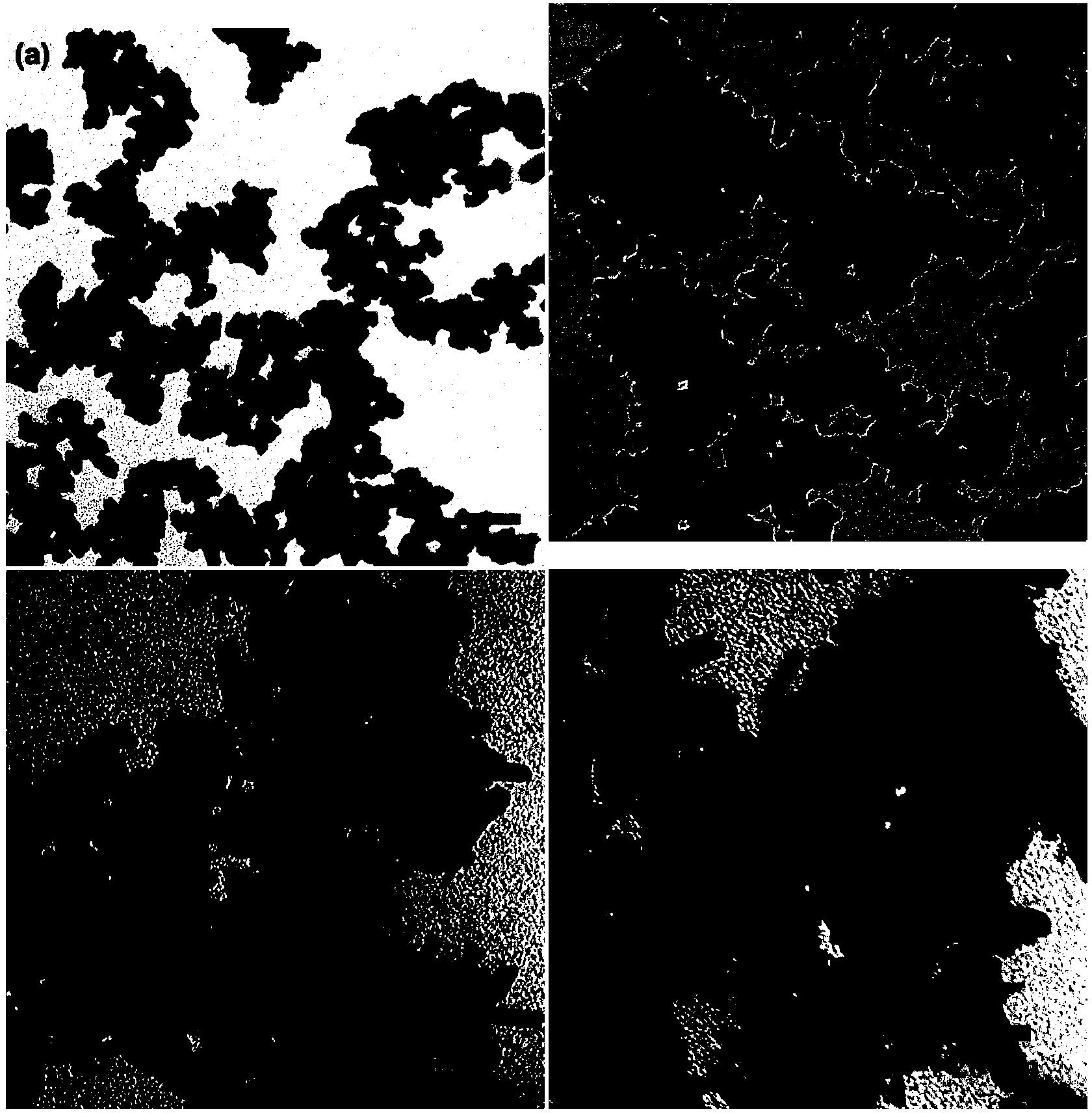

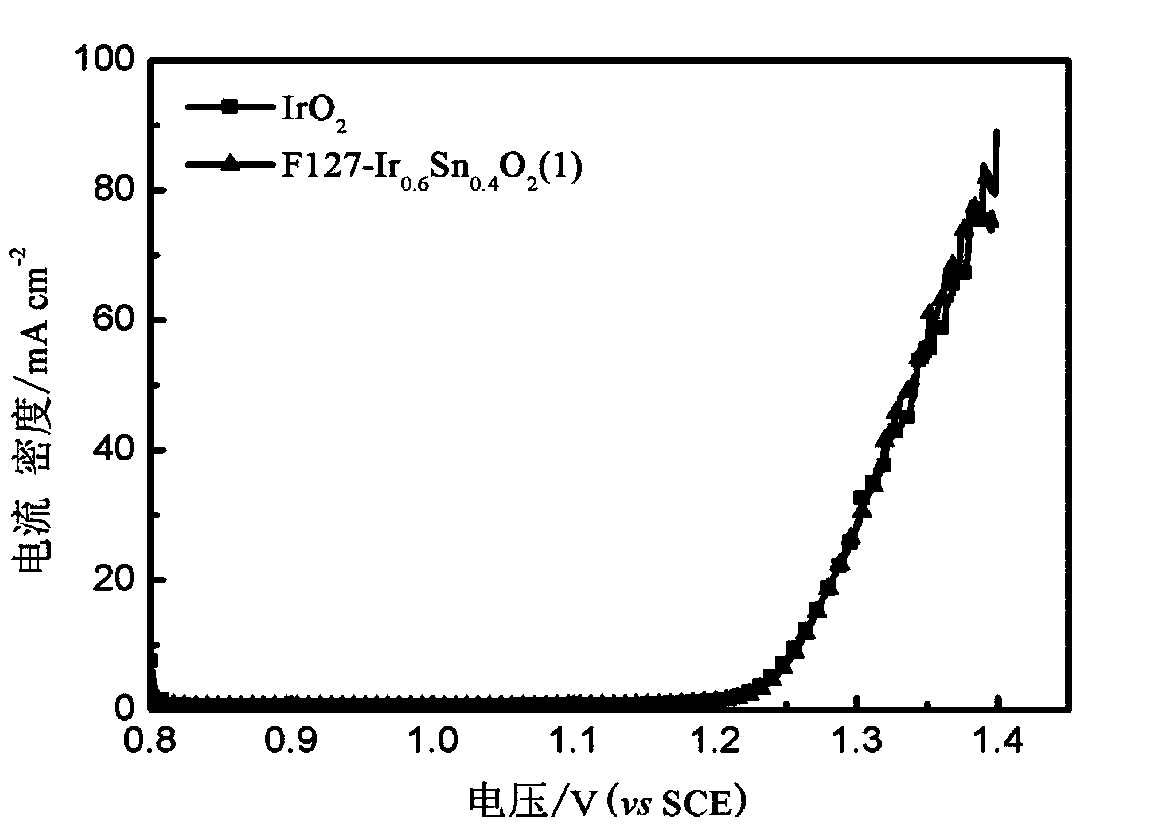

Embodiment 1

[0025] The precursor salt of iridium IrCl 3 ·xH 2 O (Ir content 54%) was added to the triblock polymer In the aqueous solution of F127, make Ir:F127=100:1 (by mol, the same below), stir at a high speed in an oil bath at 60°C for 6 hours, and slowly add a solution of 1M NaBH4+F127 dropwise (the concentration of F127 and the dissolved metal salt Same), make NaBH4:Ir=10:1, stir for 12h, let stand at room temperature for 6h, and centrifuge the sample. The lower layer of powder was washed 4 times with anhydrous ethanol solution, and placed in a vacuum desiccator at 60°C for 24 hours. After careful grinding, it was transferred to a tube furnace and baked at 500 °C for 2 h with a heating rate of 2 °C min -1 . After natural cooling, the IrO 2 .

Embodiment 2

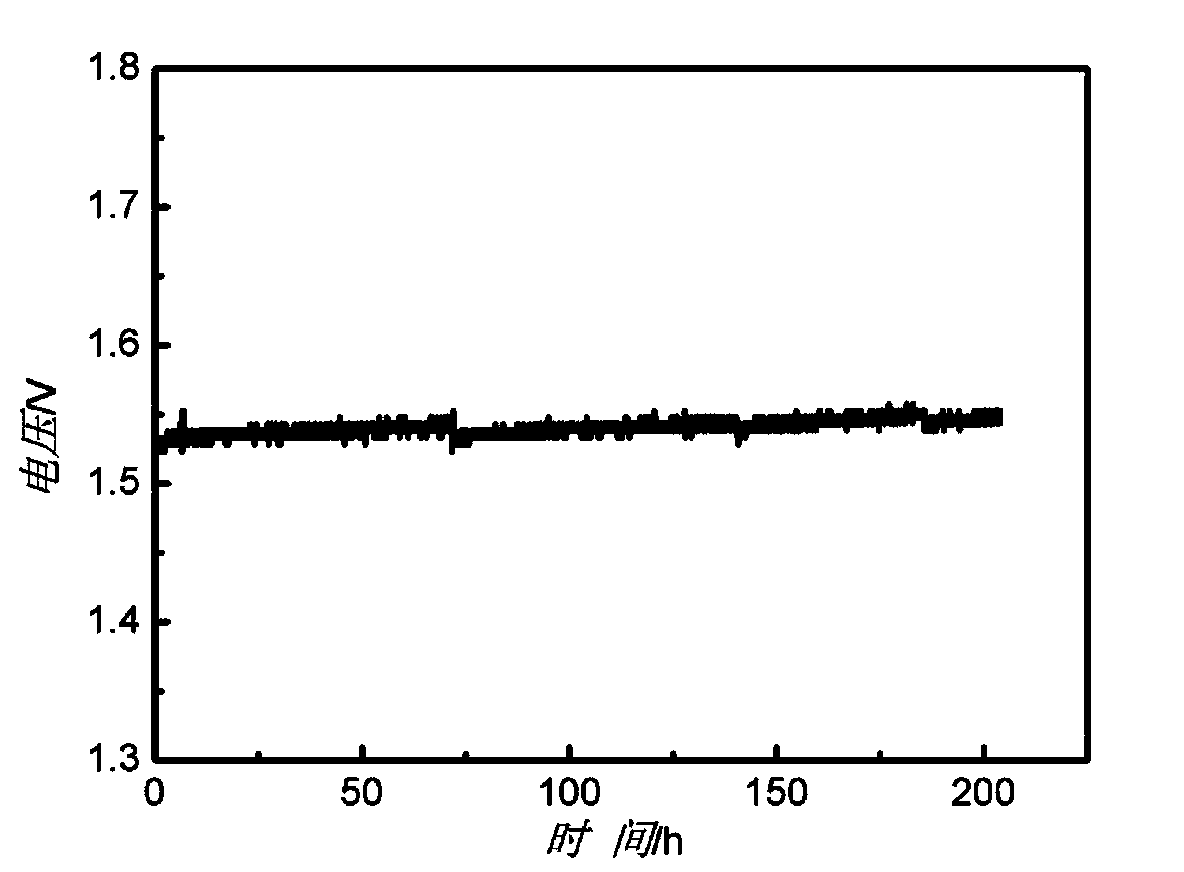

[0027] Adopt the same method of embodiment 1 to test, but the added IrCl 3 ·xH 2 O is changed to SnCl containing 3 to 5 crystal waters 4 with H 2 IrCl 6 , making Ir 0.6 sn 0.4 o 2 , denoted as F127-Ir 0.6 sn 0.4 o 2 (1).

Embodiment 3

[0029] The same method as in Example 2 was used to test, but the amount of F127 added was changed to Ir: F127=10:1 to obtain F127-Ir 0.6 sn 0.4 o 2 , denoted as F127-Ir 0.6 sn 0.4 o 2 (2).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com