Jujube polysaccharide and preparation method thereof

A technology of jujube and polysaccharide, which is used in food preparation, antidote, food science, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

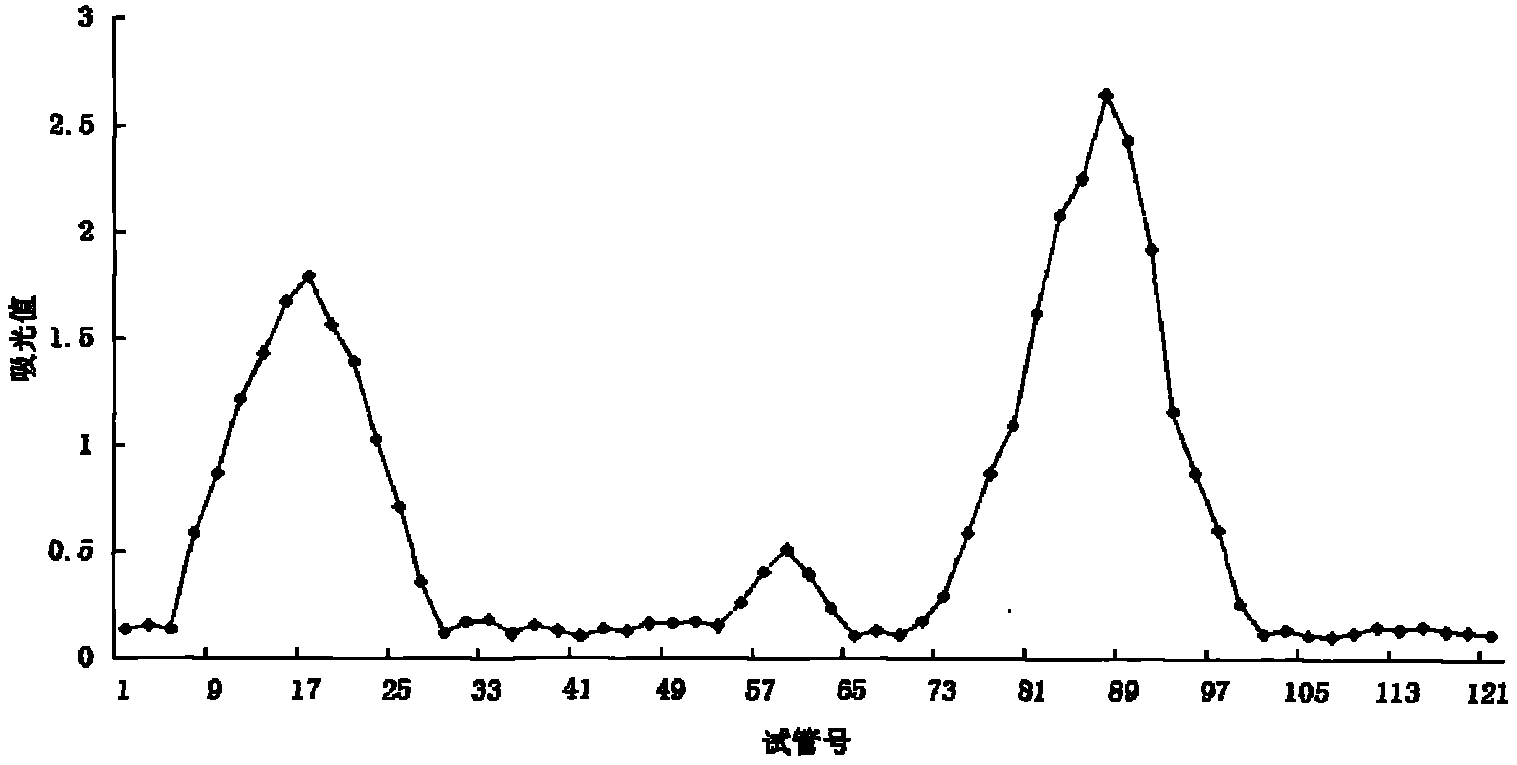

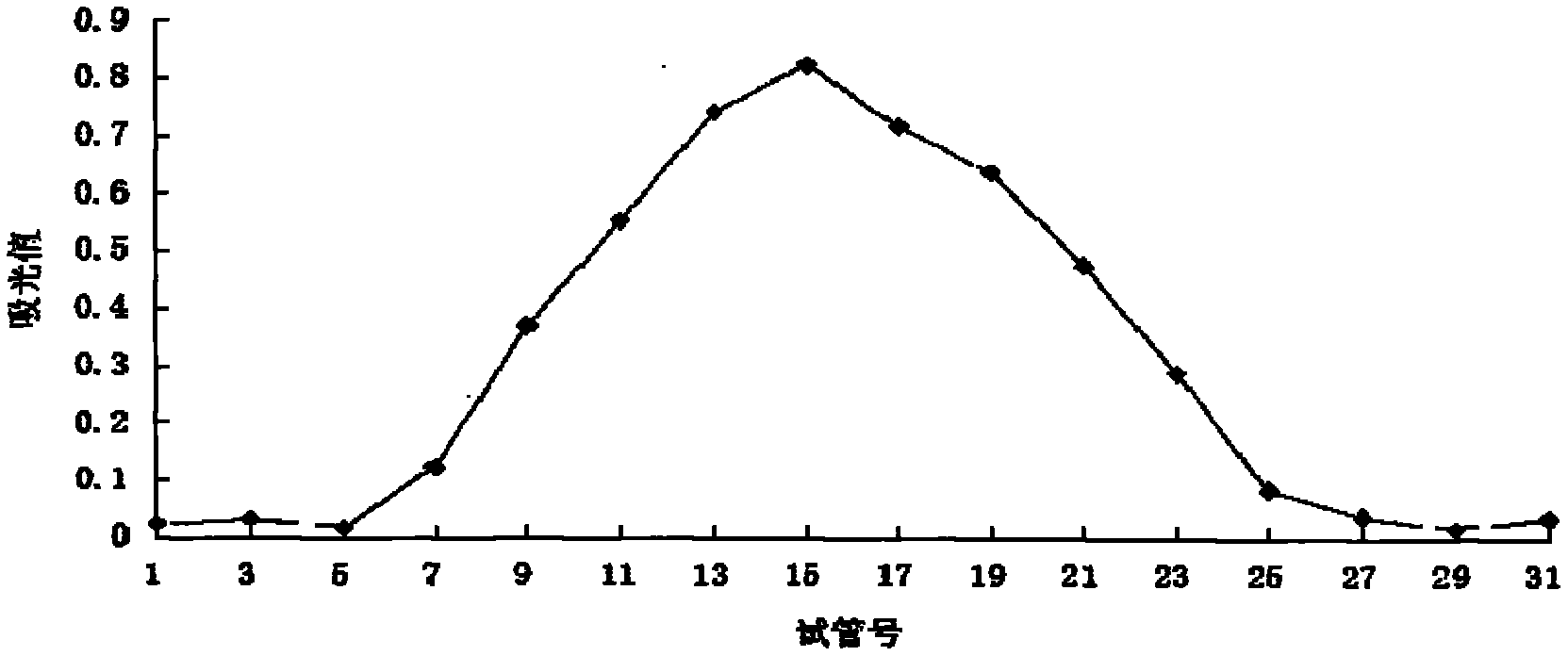

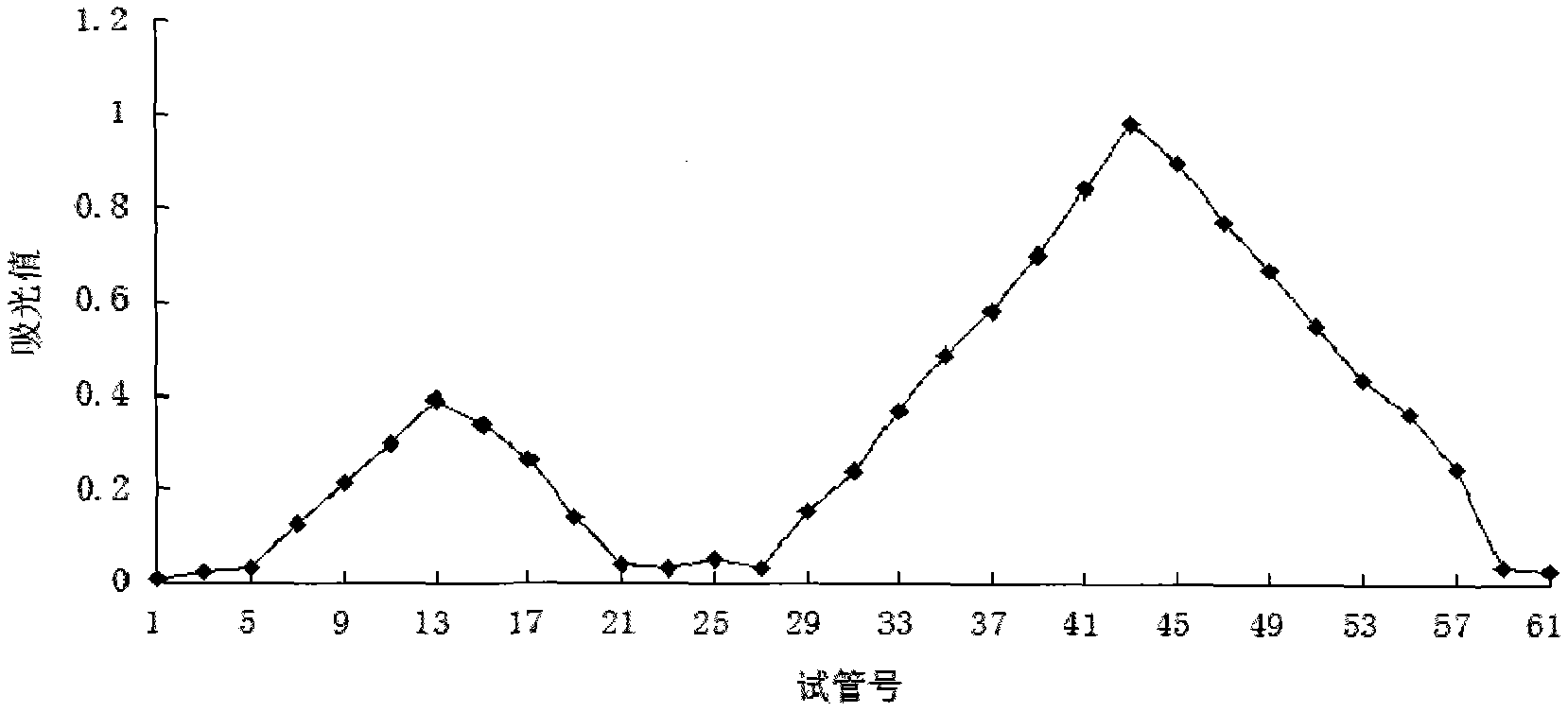

Image

Examples

Embodiment 1

[0066] Example 1: Weigh 40g of jujube, control the ratio of solid to liquid to 1:8, extract in hot water at 75°C for 4h, place in an ultrasonic vessel, and extract at 45°C for 17min, the obtained crude polysaccharide (JP) The yield was 2.91%; the obtained crude polysaccharide was made into a 4% solution, and 70 mL of crude polysaccharide solution was shaken at a constant temperature (120 r / min) for 3 hours with 10 g of activated carbon, and then filtered. The decolorization rate and polysaccharide preservation rate of the obtained solution were 50.91 %, 64.71%; take 20mL of decolorized polysaccharide solution, put it in a water bath at 37°C to preheat for 10min, add 0.3% papain and enzymolyze it at 50°C for 1h, put it in a boiling water bath to inactivate the enzyme for 10min, cool to room temperature, then add 2 mL of 12% trichloroacetic acid, stir magnetically for 30 min, let stand for 2 h, and centrifuge at 4000 r / min for 10 min to discard the precipitate. The protein remova...

Embodiment 2

[0067] Example 2: Weigh 40g of jujube, control the ratio of solid to liquid to be 1:15, extract in hot water at 75°C for 4 hours, cool it down to 40°C, add 0.3% pectinase, control the pH to 4.5, and extract Extracted for 2h, the obtained crude polysaccharide (JP) yield was 3.63%; the obtained crude polysaccharide was made into a 4% solution, and 30% H 2 o 2 5mL, stirred evenly, and kept at 40°C for 1h. The decolorization rate and polysaccharide preservation rate of the obtained solution were 73.63% and 33.82% respectively; % papain was enzymatically hydrolyzed at 50°C for 1.5h, put it in a boiling water bath to inactivate the enzyme for 10min, cooled to room temperature, then added 2mL of 12% trichloroacetic acid, stirred magnetically for 30min, stood still for 2h, centrifuged at 4000r / min for 10min and discarded Remove the precipitate, and the protein removal rate and polysaccharide preservation rate of the obtained solution are 55.02% and 63.55% respectively; put the decolo...

Embodiment 3

[0068] Example 3: Weigh 40g of jujube, control the ratio of solid to liquid to 1:12, extract in hot water at 75°C for 4h, place in an ultrasonic vessel, and extract at 50°C for 17min, the obtained crude polysaccharide (JP) The yield was 1.73%; the obtained crude polysaccharide was made into a 4% solution, and 70 mL of the crude polysaccharide solution was shaken at a constant temperature (120 r / min) for 3 hours with 10 g of macroporous resin AB-8, and then filtered. The decolorization rate of the obtained solution and the polysaccharide The preservation rates were 38.37% and 76.54% respectively; put the decolorized and deproteinized polysaccharide solution into a dialysis bag, dialyze in deionized water, replace the deionized water every 6 hours, and continue dialysis for 48 hours; -52 column, eluted with 0.1mol / L NaCl, no eluted peak was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com