Yellowing-resistant photosensitive solder resist ink and preparation method thereof

A photosensitive solder resist ink, yellowing resistance technology, applied in ink, optomechanical equipment, optics, etc., can solve the core technology in the hands of foreigners, can not meet the requirements of LED use, poor chemical resistance, heat resistance and other problems , to achieve the effect of good light curing performance, good UV curing performance and strong heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

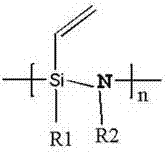

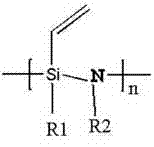

Method used

Image

Examples

Embodiment 1

[0034] With 150gβ-hydroxyethyl acrylate modified melamine formaldehyde resin, 5g polysilazane resin, 118g titanium dioxide, 5g octadecylamine acetate dispersant, 5g TEPO photoinitiator, 5g 1173 photoinitiator, 10g gas phase dioxide Mix silicon and 2g ultramarine blue evenly, use a high-speed disperser, adjust the speed to 1100rpm, stir and disperse for 30min, and then grind 5 times with a three-roller machine until the fineness is below 20μm to obtain the main agent.

[0035] Mix 50g trimethylolpropane triacrylate, 50g pentaerythritol tetraacrylate, 80g titanium dioxide, and 50g epoxy resin evenly, use a high-speed disperser, adjust the speed to 1100rpm, stir and disperse for 30min, and then grind 5 times with a three-roller machine , until the fineness is below 20 μm, the curing agent is prepared.

[0036] Mix the main agent and the curing agent in a ratio of 6:1, add 5 g of silicone defoamer, stir and disperse evenly, and then the anti-yellowing photosensitive solder resist ...

Embodiment 2

[0048]With 100gβ-hydroxyethyl acrylate modified melamine formaldehyde resin, 10g polysilazane resin, 100g titanium dioxide, 3g octadecylamine acetate dispersant, 3g TEPO photoinitiator, 3g 1173 photoinitiator, 6g talcum powder, Mix 1.5g of ultramarine blue evenly, use a high-speed disperser, adjust the speed to 1100rpm, stir and disperse for 30min, and then use a three-roller to grind 5 times until the fineness is below 20μm to obtain the main agent.

[0049] Mix 30g trimethylolpropane triacrylate, 40g pentaerythritol tetraacrylate, 60g titanium dioxide, and 40g epoxy resin evenly, use a high-speed disperser, adjust the speed to 1100rpm, stir and disperse for 30min, and then grind 5 times with a three-roller machine , until the fineness is below 20 μm, the curing agent is prepared.

[0050] Mix the main agent and the curing agent in a ratio of 4:1, add 4g of silicone defoamer, stir and disperse evenly, and then the anti-yellowing photosensitive solder resist ink for LEDs of th...

Embodiment 3

[0062] With 50gβ-hydroxyethyl acrylate modified melamine formaldehyde resin, 15g polysilazane resin, 79g titanium dioxide, 2g octadecylamine acetate dispersant, 2g TEPO photoinitiator, 2g 1173 photoinitiator, 4g kaolin, 1g Mix the ultramarine blue evenly, use a high-speed disperser, adjust the speed to 1100rpm, stir and disperse for 30 minutes, and then grind it with a three-roller machine for 5 times until the fineness is below 20μm to obtain the main ingredient.

[0063] Mix 15g trimethylolpropane triacrylate, 20g pentaerythritol tetraacrylate, 40g titanium dioxide, and 15g epoxy resin evenly, use a high-speed disperser, adjust the speed to 1100rpm, stir and disperse for 30min, and then grind 5 times with a three-roller machine , until the fineness is below 20 μm, the curing agent is prepared.

[0064] Mix the main agent and the curing agent in a ratio of 2:1, add 2g of silicone defoamer, stir and disperse evenly, and then the anti-yellowing photosensitive solder resist ink ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gloss | aaaaa | aaaaa |

| Gloss | aaaaa | aaaaa |

| Gloss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com