Nitrogen oxide fluorescent powder, preparation method thereof and luminescent device containing the fluorescent powder

A technology of nitrogen oxides and phosphors, applied in chemical instruments and methods, luminescent materials, electrical components, etc., can solve the problems of decreased luminous brightness and poor thermal stability, and achieve low cost, excellent thermal stability, and high color rendering performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

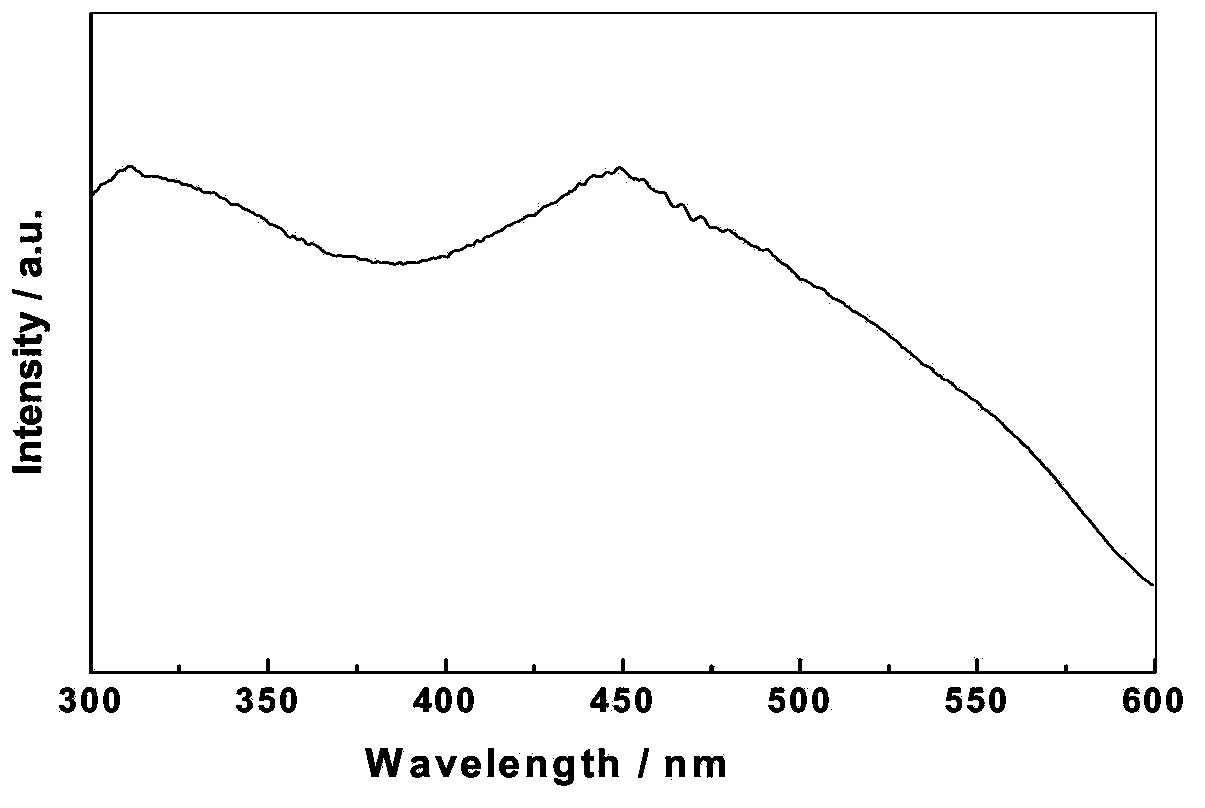

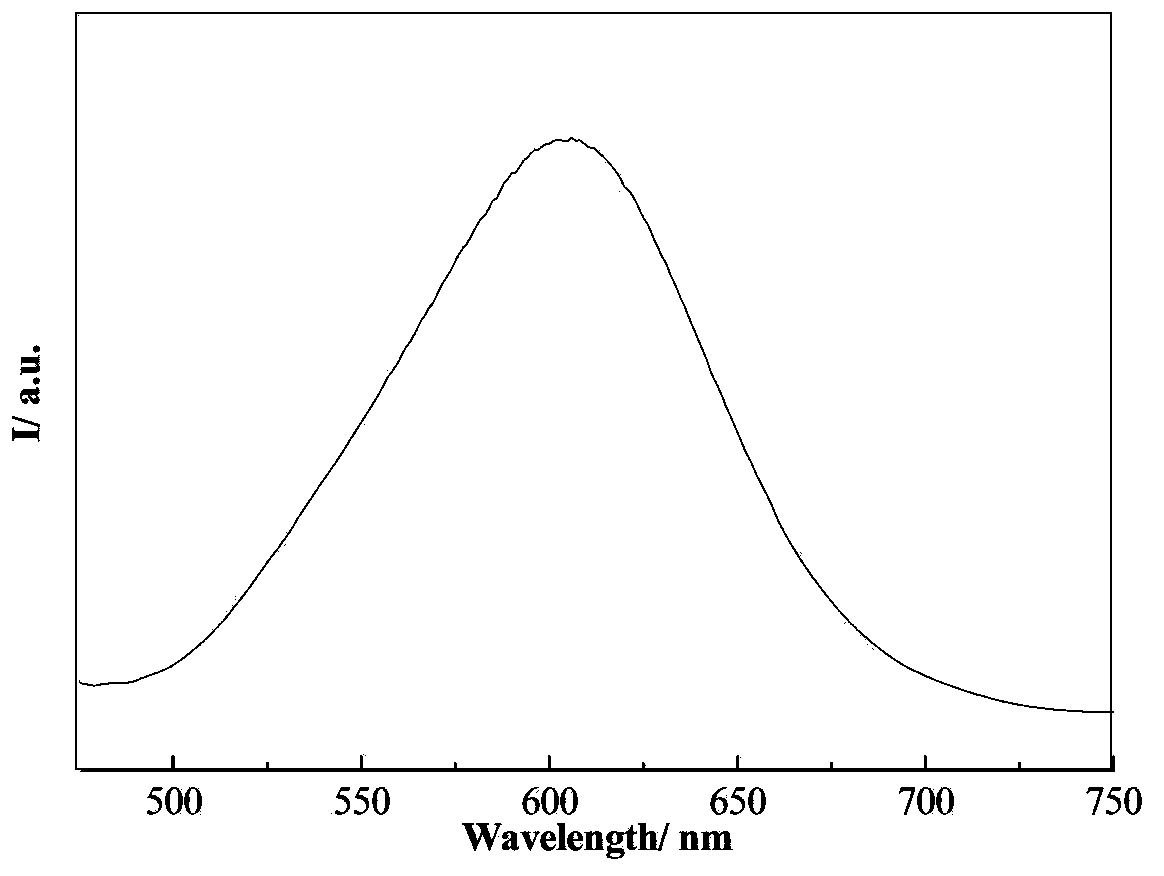

Image

Examples

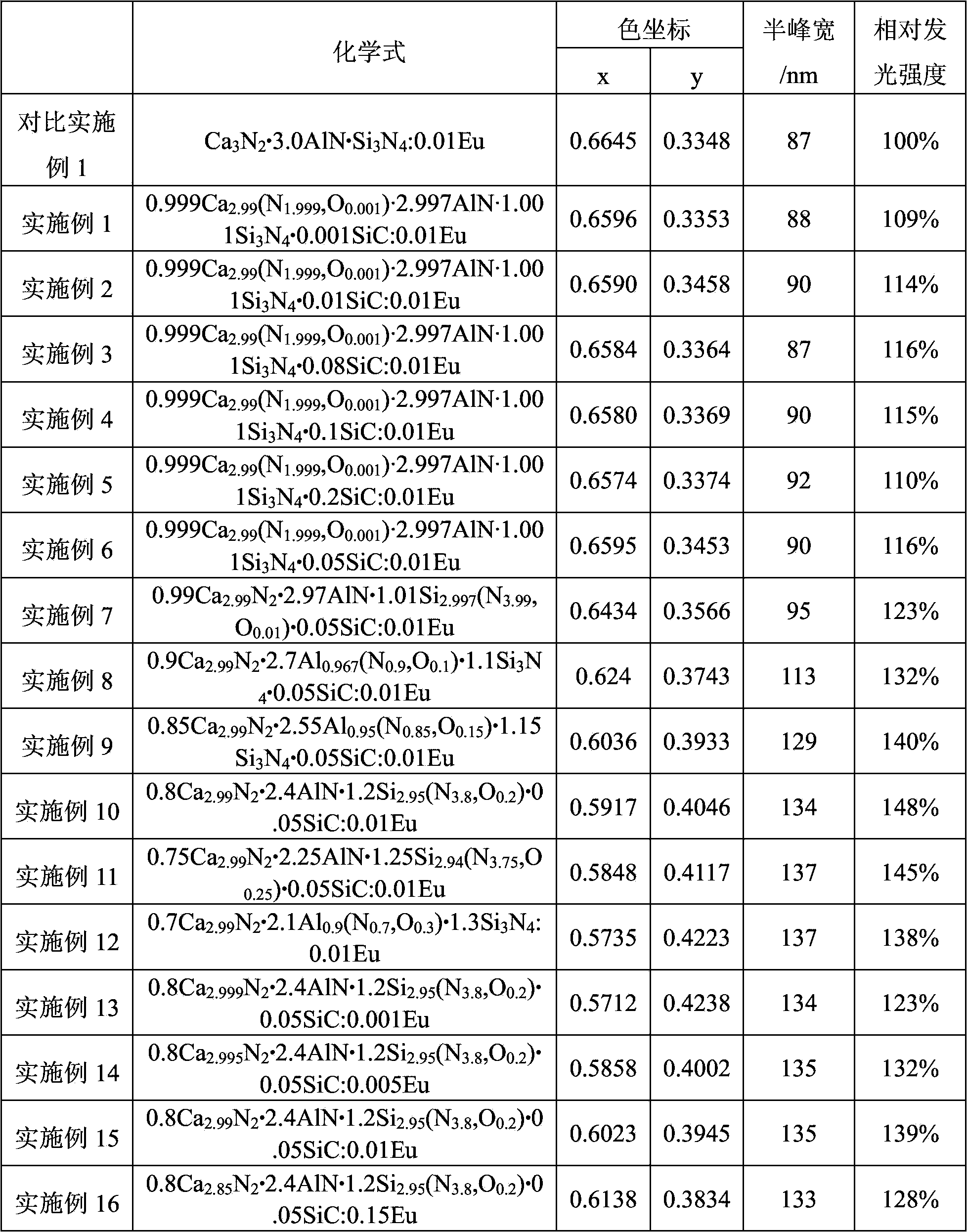

Embodiment 1

[0040] The chemical formula of this embodiment is 0.999Ca 2.99 (N 1.999 , O 0.001 )·2.997AlN·1.001Si 3 N 4 0.001SiC:0.01Eu. The manufacturing method is to weigh silicon nitride (4N), silicon dioxide (4N), aluminum nitride (4N), calcium nitride (4N), europium nitride (4N), silicon carbide (4N) according to the stoichiometric ratio and metal calcium, and mix them evenly. After the mixed raw materials are kept at 1500°C for 3 hours under a nitrogen-hydrogen atmosphere, the temperature is lowered to below 100°C. After taking them out, they are ground, washed, dried and sieved. deal with. The color coordinates, half-peak width and relative luminous intensity of the obtained phosphor powder are shown in Table 1.

Embodiment 2

[0042] The chemical formula of this embodiment is 0.999Ca 2.99 (N 1.999 , O 0.001 )·2.997AlN·1.001Si 3 N 4 0.01SiC:0.01Eu. The manufacturing method is to weigh silicon nitride (4N), aluminum nitride (4N), aluminum oxide (4N), calcium nitride (4N), europium oxide (4N), calcium carbonate (4N), carbonized Silicon (4N) and fully mixed evenly. After the mixed raw materials were kept at 1500°C for 3 hours under a nitrogen-hydrogen atmosphere and a pressure of 1MPa, the temperature was lowered to below 100°C. After taking them out, they were ground, washed, dried and passed Sieve and other post-processing. The color coordinates, half-peak width and relative luminous intensity of the obtained phosphor powder are shown in Table 1.

Embodiment 3

[0044] The chemical formula of this embodiment is 0.999Ca 2.99 (N 1.999 , O 0.001 )·2.997AlN·1.001Si 3 N 4 0.08SiC:0.01Eu. Weigh silicon nitride (4N), aluminum nitride (4N), aluminum nitrate (4N), aluminum oxide (4N), calcium nitride (4N), calcium oxide (4N), europium oxide (4N) according to the stoichiometric ratio , silicon carbide (4N) and mix well. Its manufacturing method and post-treatment process are basically the same as in Example 1. The color coordinates, half-peak width and relative luminous intensity of the obtained phosphor powder are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| color rendering index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com