High-resistance temperature coefficient vanadium oxide film preparation method

A technology of vanadium oxide thin film and temperature coefficient, applied in ion implantation plating, metal material coating process, coating, etc., can solve the problem of increasing vanadium oxide thin film, increasing the complexity and difficulty of reactive sputtering process, and intrinsic noise of thin film Increase and other issues to achieve good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

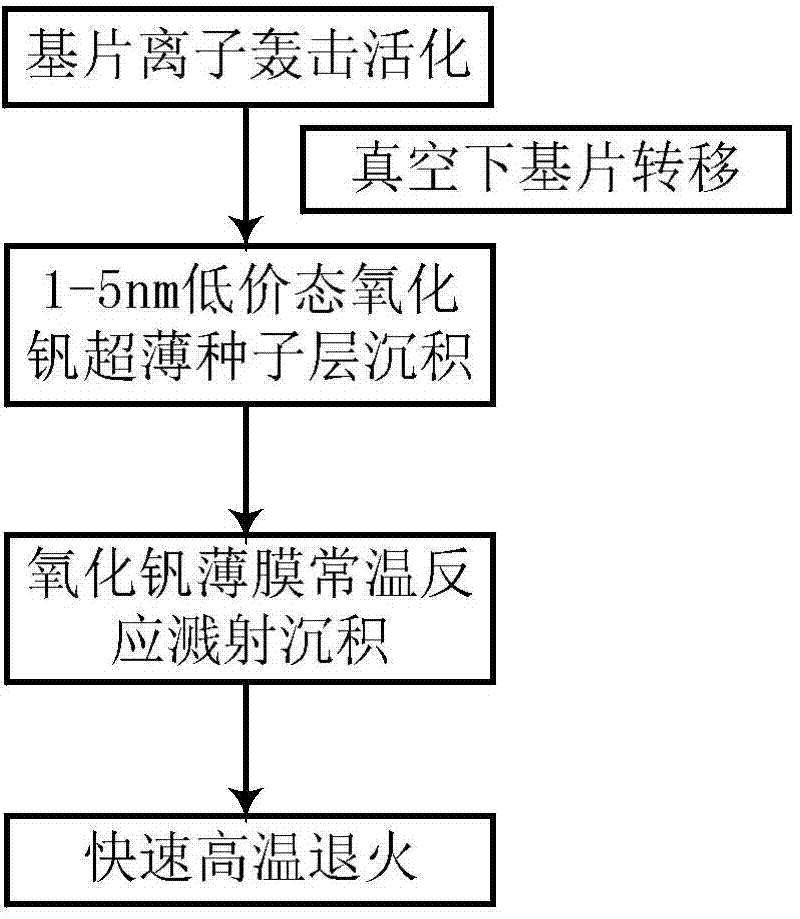

[0022] The preparation method provided by the present invention is suitable for preparing vanadium oxide thermosensitive films with high resistance temperature coefficient, and the preparation process is as follows:

[0023] (1) Activate the surface of the substrate in an oxygen-rich atmosphere, and then transfer the processed substrate to the sputtering chamber.

[0024] (2) Two-step sputtering deposition: at room temperature, first sputter with low oxygen or even oxygen free, deposit a seed layer of 1-5nm thick with high nucleation density on the surface of the substrate, and then sputter the vanadium oxide film with normal reaction Deposition.

[0025] (3) Rapid annealing treatment: in the same atmosphere as reactive sputtering, at a predetermined temperature of 300~500℃, using annealing equipment such as infrared rapid annealing furnace, the sputtered vanadium oxide film is subjected to a short time high temperature for 2-10 minutes Heat treatment.

Embodiment 1

[0028] This example is used to evaluate the temperature coefficient of resistance of the vanadium oxide thin film prepared on the silicon wafer deposited with the silicon nitride thin film by the method of the present invention. details as follows:

[0029] Deposit ~100nm thick Si on silicon wafer using CVD process 3 N 4 The thin film is cleaned and dried by a standard semiconductor cleaning process and used as the substrate for the deposition of the vanadium oxide thin film; before sputtering, the vacuum degree of the vacuum chamber where the Kaufman source is located is pumped to better than 5.0×10 -4 After Pa, open the intake valve and pass in O 2 / Ar flow ratio 1:6 ultra-high purity Ar and O 2 , And maintain the vacuum at ~3.0×10 -1 Pa, and then ion bombard the surface of the substrate for 3 minutes. The activated substrate is transferred to the sputtering chamber under the vacuum environment, and the two-step sputtering deposition at room temperature is carried out: 2 / Ar flo...

Embodiment 2

[0037] Through this example to evaluate the method of the present invention in depositing SiO 2 The temperature coefficient of resistance of the vanadium oxide thin film prepared on the thin silicon wafer. details as follows:

[0038] Deposit ~100nm thick SiO on silicon wafer using CVD process 2 The thin film is cleaned and dried by a standard semiconductor cleaning process and used as the substrate for the deposition of the vanadium oxide thin film; before sputtering, the vacuum degree of the vacuum chamber where the Kaufman source is located is pumped to be better than 5.0×10 -4 After Pa, open the intake valve and pass in O 2 / Ar flow ratio 1:15 ultra-high purity Ar and O 2 , And maintain the vacuum at ~5.0×10 -1 Pa, then ion bombard the surface of the substrate for 5 minutes. The activated substrate is transferred to the sputtering chamber under the vacuum environment, and the two-step sputtering deposition at room temperature is carried out: 2 / Ar flow ratio is 1:45 to deposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com