Hierarchic porous La2Zr2O7 ceramic and preparation method thereof

A hierarchical porous and ceramic technology, which is applied to ceramic products, other household utensils, household utensils, etc., can solve the problem of hierarchical porous multi-element rare earth compound ceramics, etc., achieve uniform and stable structure, no corrosion of equipment, and improve high temperature stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

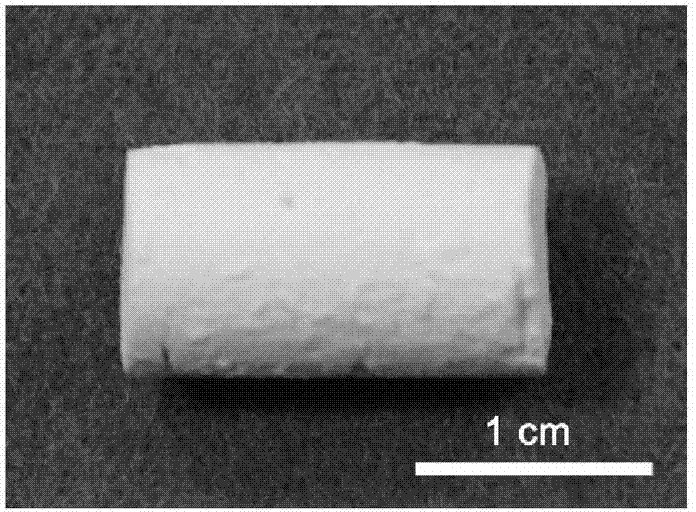

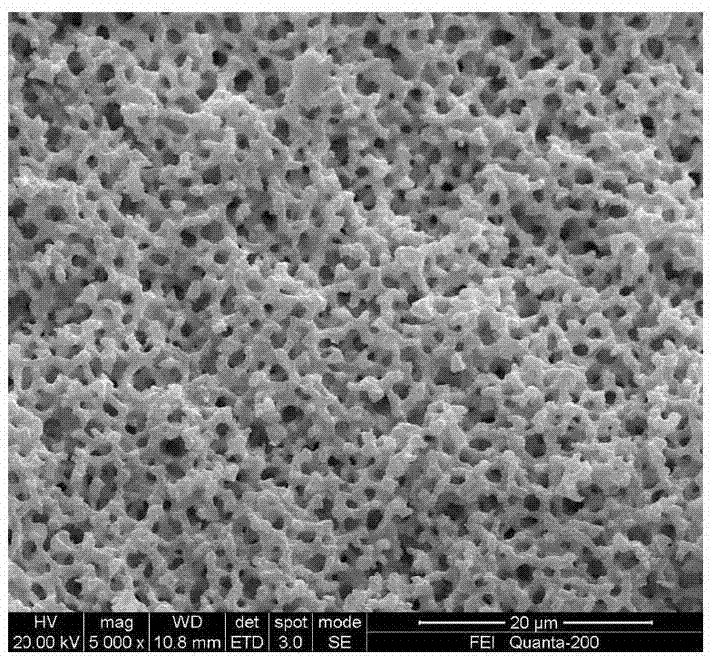

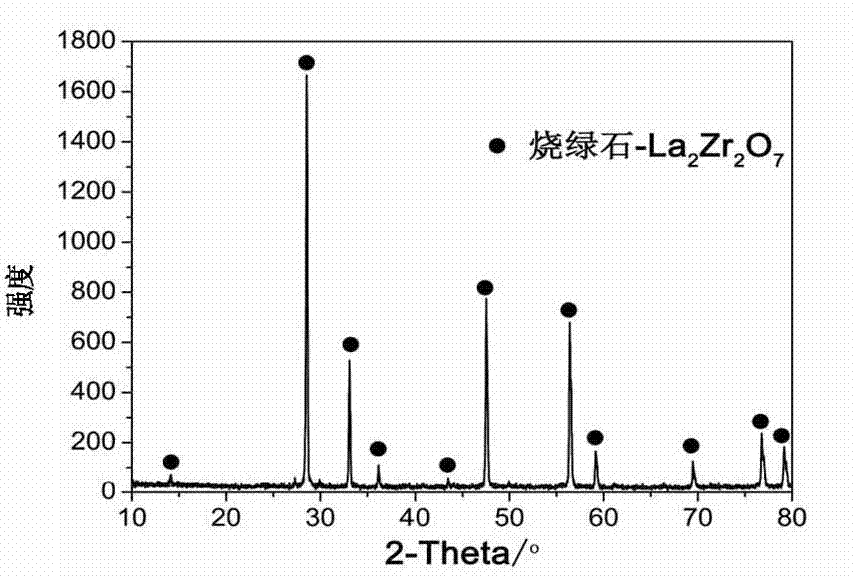

[0032] A kind of hierarchical porous La of the present invention 2 Zr 2 o 7 ceramic, the graded porous La 2 Zr 2 o 7 Ceramics are binary oxide hierarchical porous ceramics with micro-mesopores and macro-pores, in which the diameter of micro-mesopores is 1nm-4nm, the diameter of macropores is 1μm-3μm, and the specific surface area is 149.94m 2 / g, no phase change after heat treatment at 1600°C in air, no corrosion in concentrated nitric acid.

[0033] A kind of hierarchical porous La of above-mentioned present embodiment 2 Zr 2 o 7 The preparation method of pottery, comprises the following steps:

[0034] (1) Preparation of precursor solution: ZrOCl 2 ·8H 2 O, La(NO 3 ) 3 ·6H 2 O was slowly added to a mixed solvent composed of deionized water and ethanol, and stirred continuously until dissolved to obtain a precursor solution, in which ZrOCl 2 ·8H 2 O:La(NO 3 ) 3 ·6H 2 The molar ratio of O: deionized water: ethanol is 1:1:50:20.

[0035] (2) Prepare the sol: ...

Embodiment 2

[0041] A kind of hierarchical porous La of the present invention 2 Zr 2 o 7 ceramic, the graded porous La 2 Zr 2 o 7 Ceramics are binary oxide hierarchical porous ceramics with micro-mesopores and macro-pores, in which the pore size of the micro-mesopores is 1nm-3nm, the pore size of the macro-pores is 1μm-5μm, and the specific surface area is 118.81m 2 / g, no phase change after heat treatment at 1600°C in air, no corrosion in concentrated nitric acid.

[0042] A kind of hierarchical porous La of above-mentioned present embodiment 2 Zr 2 o 7 The preparation method of pottery, comprises the following steps:

[0043] (1) Preparation of precursor solution: Zr(NO 3 ) 4 ·5H 2 O, La(NO 3 ) 3 ·6H 2 O was slowly added into a mixed solvent composed of deionized water and ethanol, and stirred continuously until dissolved to obtain a precursor solution, in which Zr(NO 3 ) 4 ·5H 2 O:La(NO 3 ) 3 ·6H 2 The molar ratio of O: deionized water: ethanol is 1:1:80:40.

[0044...

Embodiment 3

[0050] A kind of hierarchical porous La of the present invention 2 Zr 2 o 7 ceramic, the graded porous La 2 Zr 2 o 7 Ceramics are binary oxide hierarchical porous ceramics with micro-mesopores and macro-pores, in which the diameter of micro-mesopores is 2nm-5nm, the diameter of macropores is 0.5μm-2μm, and the specific surface area is 43.05m 2 / g, no phase change after heat treatment at 1600°C in air, no corrosion in concentrated nitric acid.

[0051] A kind of hierarchical porous La of above-mentioned present implementation 2 Zr 2 o 7 The preparation method of pottery, comprises the following steps:

[0052] (1) Preparation of precursor solution: ZrOCl 2 ·8H 2 O, LaCl 3 ·6H 2 O was slowly added to a mixed solvent composed of deionized water and ethanol, and stirred continuously until dissolved to obtain a precursor solution, in which ZrOCl 2 ·8H 2 O: LaCl 3 ·6H 2 The molar ratio of O: deionized water: ethanol is 1:1:10:10.

[0053] (2) Preparation of sol: Stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com