Multilayer AlCrN cutting tool coating and preparation method thereof

A cutting tool and coating technology, applied in the field of tool coating and its preparation, can solve problems such as reducing internal stress, and achieve the effect of reducing internal stress and improving tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

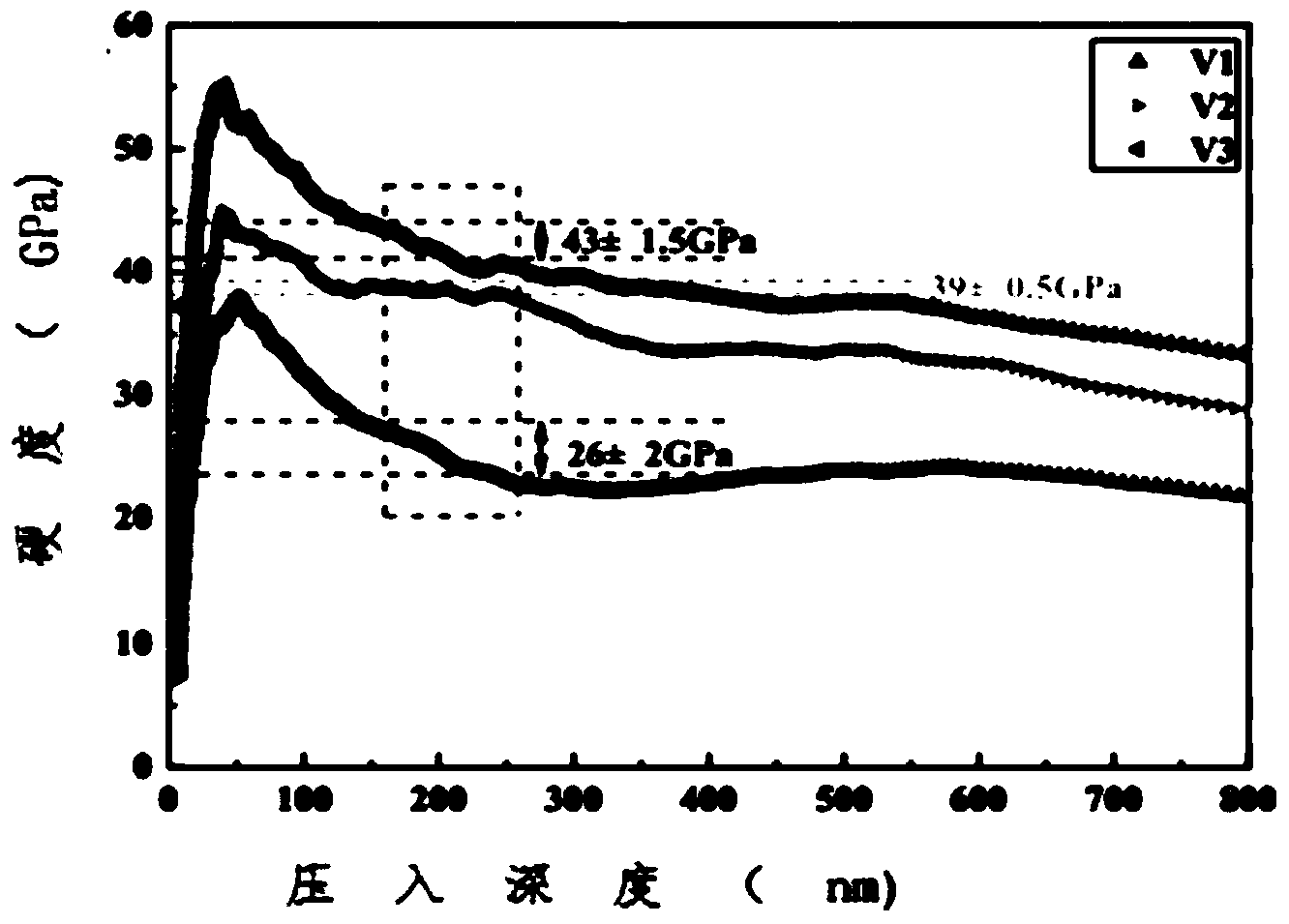

[0025] Clean the cemented carbide sample with alcohol and acetone, dry it with an air gun, and place it on the substrate holder in the chamber. Use a mechanical pump and a molecular pump to pump the background vacuum of the vacuum chamber to 3-5×10 -3 Pa, enter Ar gas, increase the pressure to 0.2Pa, apply a high bias voltage of -1000V, and glow clean for 5 to 30 minutes; after cleaning, adjust the vacuum to 3×10 -1 Pa, open the metal Cr target, bombard the workpiece substrate with a Cr interface implant layer with a thickness of about 150nm for 20 minutes, and keep the bias voltage at -500~-800V; after the bombardment is completed, the bias voltage drops to -150V, and the duty cycle is 80%. Cut off the Ar gas, pass in N 2 , control N 2 The gas pressure is 1.2-2Pa, and the metal CrN bonding layer is deposited, the arc voltage is 20-30V, the arc current is 65-80A, and the deposition time is 10-20min. After the deposition of the CrN binding layer is completed, the AlCrX alloy...

Embodiment 2

[0030]Clean the solid carbide rod-shaped milling cutter with alcohol and acetone, dry it with an air gun, and place it on the substrate holder in the chamber. Use a mechanical pump and a molecular pump to pump the background vacuum of the vacuum chamber to 3-5×10 -3 Pa, introduce Ar gas, increase the pressure to 0.2-1Pa, apply a high bias voltage of -1000V, and glow clean for 10-30min; after cleaning, adjust the vacuum to 3×10 -1 Pa, open the metal Cr target, bombard a Cr implantation layer with a thickness of about 150nm on the workpiece substrate for 20 minutes, and keep the bias voltage at -500~-800V; Out of Ar gas, into N 2 , control N 2 The gas pressure is 1.2-2Pa, and the metal CrN bonding layer is deposited, the arc voltage is 20-30V, the arc current is 65-80A, and the deposition time is 10-20min. After the deposition of the CrN binding layer is completed, the AlCrX alloy target is turned on. In the AlCrX alloy target of this embodiment, X is a C element, the target ...

Embodiment 3

[0034] Clean the carbide end mill with alcohol and acetone, dry it with an air gun and place it on the substrate holder in the chamber. Use a mechanical pump and a molecular pump to pump the background vacuum of the vacuum chamber to 3-5×10 -3 Pa, introduce Ar gas, increase the pressure to 0.2-1Pa, apply a high bias voltage of -1000V, and glow clean for 10-30min; after cleaning, adjust the vacuum to 3×10 -1 Pa, open the metal Cr target, bombard the workpiece substrate with a Cr implantation layer with a thickness of about 150nm for 20min, and keep the bias voltage at -600~-900V; Out of Ar gas, into N 2 , control N 2 The gas pressure is 1.2-2Pa, and the metal CrN bonding layer is deposited, the arc voltage is 20-30V, the arc current is 65-80A, and the deposition time is 10-20min. After the deposition of the CrN binding layer is completed, the AlCrX alloy target is turned on. In the AlCrX alloy target of this embodiment, X is the Y element, the target current is controlled at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com