Organic electroluminescent device and preparing method thereof

An electroluminescent device and electroluminescent technology, which are applied in the directions of organic semiconductor devices, materials of organic semiconductor devices, and electric solid devices, etc., can solve the problems of failure, penetration, and poor water vapor and oxygen barrier properties of organic electroluminescent devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

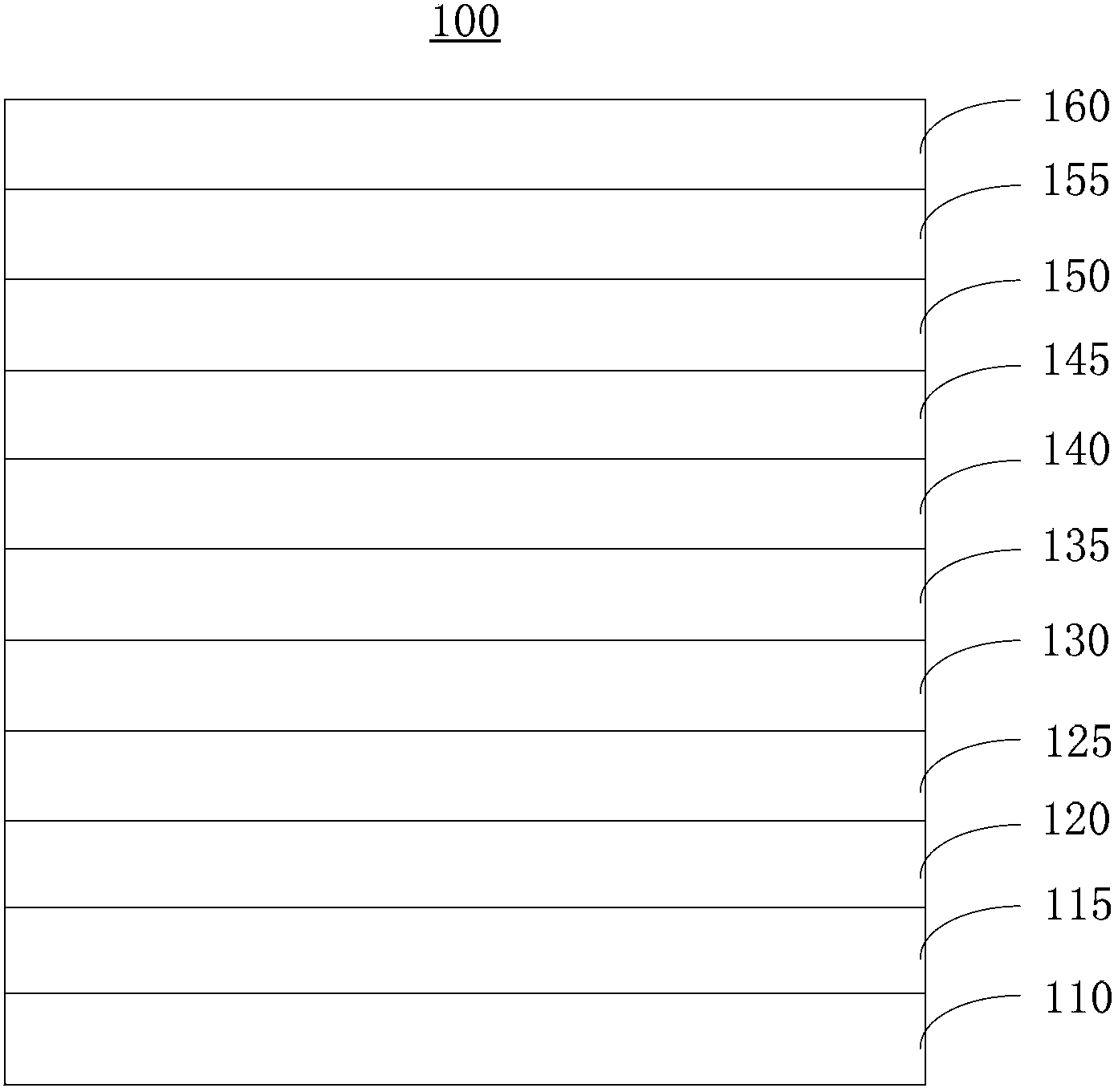

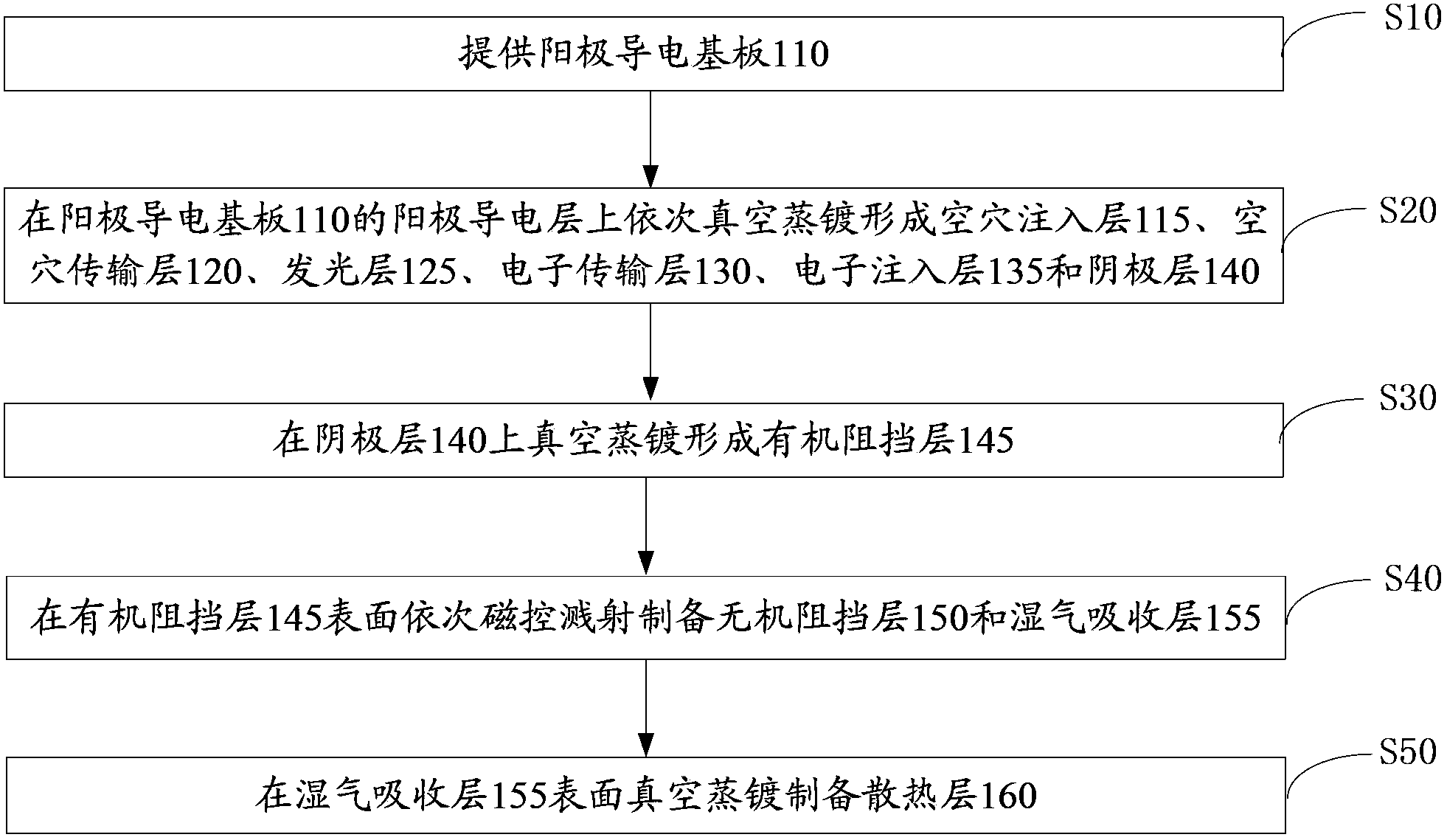

[0062] Such as figure 2 As shown, the preparation method of the above-mentioned organic electroluminescent device comprises the following steps:

[0063] S10 , providing an anode conductive substrate 110 .

[0064] Including the anode conductive layer and the substrate, the substrate can be a glass substrate or an organic film substrate, and the material of the anode conductive layer can be a conductive oxide, such as indium tin oxide (ITO), aluminum-doped zinc oxide (AZO), indium-doped zinc oxide (IZO) or fluorine-doped tin oxide (FTO), these conductive oxides are prepared on glass substrates, referred to as ITO glass, AZO glass, IZO glass, FTO glass. The anode conductive substrate can be self-made or purchased from the market. In practical applications, other suitable materials can be selected as the anode conductive substrate 110 as required. In practical applications, desired anode patterns of organic electroluminescent devices can be prepared on the anode conductive s...

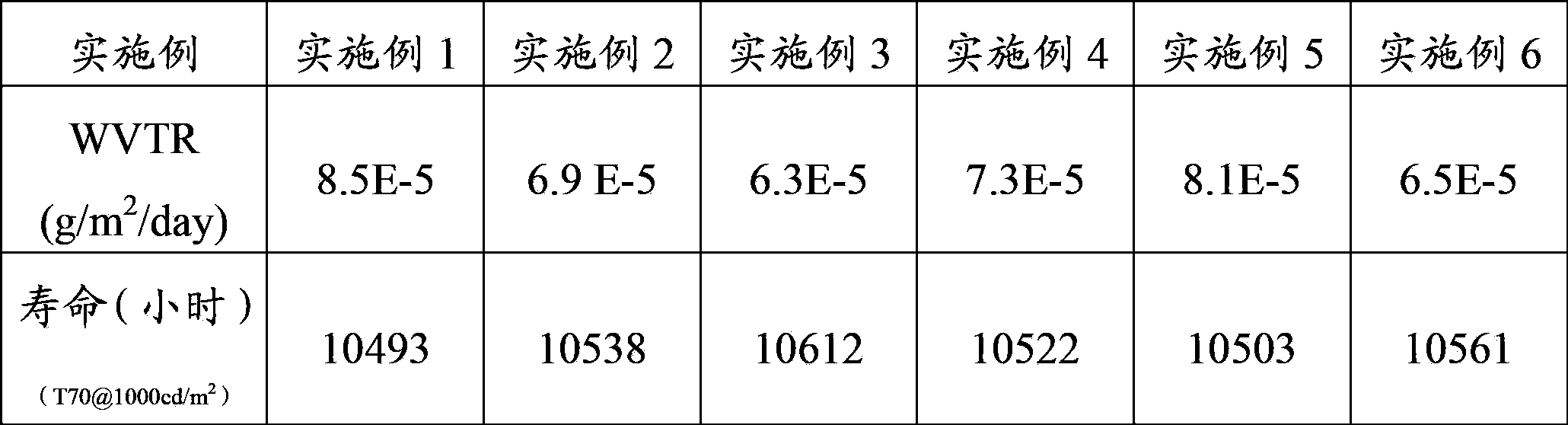

Embodiment 1

[0100] Provide an ITO glass substrate with a thickness of 100nm as a conductive substrate, and process it as follows: cleaning with acetone→cleaning with ethanol→cleaning with deionized water→cleaning with ethanol, all cleaning with an ultrasonic cleaner, each cleaning time is 5 minutes, and then Blow dry with nitrogen, and dry in an oven for later use. Surface activation treatment is also required for the cleaned ITO glass to increase the oxygen content on the surface of the conductive layer and improve the work function of the surface of the conductive layer.

[0101] In a vacuum of 3×10 -5 Under the condition of Pa, with Evaporation speed, vacuum evaporation method is used to form a hole injection layer on the ITO substrate; the material of the hole injection layer is doped with MoO 3 NPB, where MoO 3 The weight percentage of the hole transport layer is 30%, and the thickness of the formed hole transport layer is 10nm.

[0102] In a vacuum of 3×10 -5 Under the conditi...

Embodiment 2

[0112] The preparation method of the organic electroluminescence device of embodiment 2 is basically the same as embodiment 1, the difference is:

[0113] The desired anode pattern of the organic electroluminescent device is prepared on the surface-activated ITO glass.

[0114] In a vacuum of 5 x 10 -5 Under the condition of Pa, with The evaporation rate is high, and an organic barrier layer is formed on the cathode layer by vacuum evaporation. The material of the organic barrier layer is NPB, and the thickness of the formed organic barrier layer is 250 nm.

[0115] The background vacuum is 5×10 -4 Under the condition of Pa, an inorganic barrier layer is formed on the organic barrier layer by magnetron sputtering. The material of the inorganic barrier layer is Bi 2 Te and TaS 2 , where TaS 2 It accounts for 15% by weight of the inorganic barrier layer. The formed inorganic barrier layer had a thickness of 120 nm.

[0116] The background vacuum is 5×10 -4 Under the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com