A bioabsorbable hemostatic membrane

A hemostatic film, biological technology, applied in the direction of absorbent pads, medical science, bandages, etc., can solve the problems of poor hemostatic effect, slow degradation speed, and long preparation time of cross-linked films, and achieve excellent hemostasis, promote healing, and short process cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

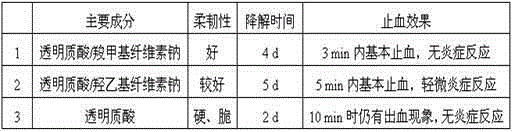

[0032] In order to investigate the effect of cellulose on the efficacy of the hemostatic membrane, in this example, hyaluronic acid / sodium carboxymethyl cellulose, hyaluronic acid / sodium hydroxyethyl cellulose and simple hyaluronic acid were prepared respectively The hemostatic membrane, compare the difference among the three.

[0033] (1) Use NaOH to adjust the pH value of deionized water to 10~12, add 1,4-butanediol diglycidyl ether, and mix well to obtain a mixed solution;

[0034] (2) Prepare three sets of gels: No. 1 dissolves 1000 kD sodium hyaluronate and 500 kD sodium carboxymethylcellulose in the mixed solution, and the mass ratio of sodium hyaluronate to sodium carboxymethylcellulose is 4 : 1, mix well and fully dissolve the biological polysaccharide, prepare sodium hyaluronate and sodium carboxymethylcellulose with 10% gel Ⅰ, the amount of 1,4-butanediol diglycidyl ether accounts for 10% of hyaluronic acid 1.25% of the total mass of sodium alginate and sodium carbo...

Embodiment 2

[0041] (1) Use NaOH to adjust the pH value of deionized water to 10~12, add 1,4-butanediol diglycidyl ether, and mix well to obtain a mixed solution;

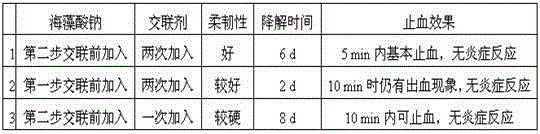

[0042] (2) Prepare three groups of gels, the mass ratio of sodium hyaluronate to sodium carboxymethylcellulose is 2:1, and the mass ratio of sodium hyaluronate to sodium alginate is 1:0.1; in gel Ⅰ, 1, The amount of 4-butanediol diglycidyl ether added is 1.25% of the total weight of sodium hyaluronate and sodium hydroxymethylcellulose: No. 1 dissolves 1500 kD sodium hyaluronate and 500 kD sodium carboxymethylcellulose in In the mixed solution, mix evenly and fully dissolve the biopolysaccharide, prepare gel I with a sodium hyaluronate concentration of 10% and a sodium carboxymethylcellulose concentration of 5%, react at 35°C for alkaline cross-linking for 4 h, and then add Gel II with 1500 kD 1% sodium alginate and cross-linking agent dissolved, the amount of 1,4-butanediol diglycidyl ether in gel II is half of that in gel I, a...

Embodiment 3

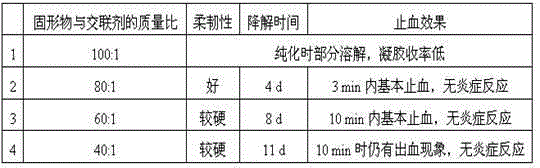

[0049] In this example, the effects of hyaluronic acid with different molecular weights on the physicochemical properties and hemostatic application effect in the preparation of the hemostatic film were investigated.

[0050] (1) Use 0.25 N NaOH to adjust the pH value of deionized water to 10~12, add 1,4-butanediol diglycidyl ether, and mix well to obtain a mixed solution;

[0051] (2) Dissolve sodium hyaluronate and 500 kD sodium carboxymethyl cellulose with molecular weights of 500 kD, 1000 kD, 1500 kD and 2000 kD respectively in the mixed solution. The mass ratio is 2:1, 1,4-butanediol diglycidyl ether accounts for 1.25% of the total weight of sodium hyaluronate and sodium carboxymethyl cellulose, mix well and fully dissolve the biological polysaccharide to prepare sodium hyaluronate Gel Ⅰ with a concentration of 10% was reacted at 35°C for alkaline cross-linking for 4 h;

[0052] (3) Add 500 kD sodium alginate into deionized water mixed with 1,4-butanediol diglycidyl ethe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com