Compound microbial fertilizer produced by fermentation and industrial waste residue and preparation method thereof

A technology for compounding microbial fertilizers and industrial waste residues, applied in fertilizer mixtures, applications, agriculture, etc., can solve problems such as environmental pollution and waste of energy, and achieve the effects of improving crop quality, improving utilization, and inhibiting growth and reproduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

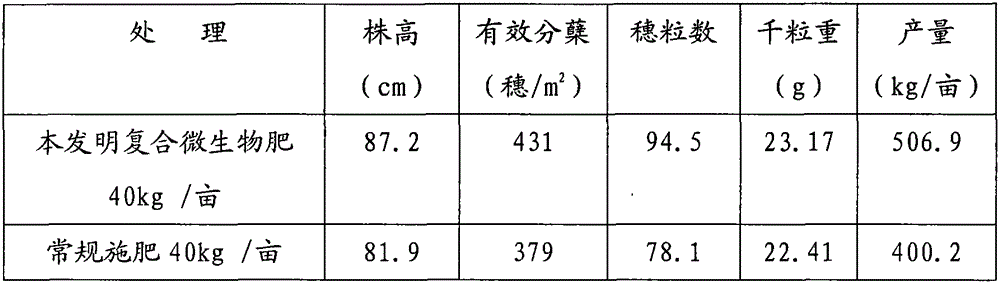

Examples

Embodiment 1

[0019] A compound microbial fertilizer produced by fermentation and industrial waste residue, the formula is as follows by weight percentage: 43% of monosodium glutamate leftover powder, 35% of 1,3-propanediol fermentation waste residue, 13.5% of dried chicken manure, 7.95% of diammonium phosphate, 0.25% of Trichoderma harzianum, 0.15% of Bacillus subtilis, and 0.15% of Bacillus jelly-like; the bacterial content of the Bacillus jelly-like powder is 10 billion cfu / g; The bacteria content is 10 billion cfu / g; the bacteria content in the Trichoderma harzianum powder is 1 billion cfu / g. Production method: grind monosodium glutamate leftover powder, 1,3-propanediol fermentation waste residue, dried chicken manure, and phosphate fertilizer into 100-mesh powder. Then use the disc granulation system to granulate, and screen the fertilizer granules with a particle size of 2mm-4mm. After Trichoderma harzianum, Bacillus subtilis, and Bacillus jelly-like are mixed according to the above ...

Embodiment 2

[0021] A compound microbial fertilizer produced by fermentation and industrial waste residue, the formula is as follows by weight percentage: 45% of monosodium glutamate leftover powder, 38% of 1,3-propanediol fermentation waste residue, 10% of dried chicken manure, 6.5% of diammonium phosphate, 0.3% of Trichoderma harzianum, 0.1% of Bacillus subtilis, 0.1% of Bacillus jelly-like; the bacterial content of the Bacillus jelly-like powder is 10 billion cfu / g; the Bacillus subtilis powder The bacteria content is 10 billion cfu / g; the bacteria content in the Trichoderma harzianum powder is 1 billion cfu / g. The preparation method is as follows: crushing monosodium glutamate leftover powder, 1,3-propanediol fermentation waste residue, dried chicken manure and phosphate fertilizer into 100-mesh powder. Then use the disc granulation system to granulate, and screen the fertilizer granules with a particle size of 2mm-4mm. After Trichoderma harzianum, Bacillus subtilis, and Bacillus jell...

Embodiment 3

[0023] A compound microbial fertilizer produced by fermentation and industrial waste residue, the formula is as follows by weight percentage: 35% of monosodium glutamate leftover powder, 45% of 1,3-propanediol fermentation waste residue, 9% of dried chicken manure, 10.5% of diammonium phosphate, 0.24% of Trichoderma harzianum, 0.13% of Bacillus subtilis, 0.13% of Bacillus jelly-like, and the bacterial content in the Bacillus jelly-like powder is 10 billion cfu / g; in the Bacillus subtilis powder The bacteria content is 10 billion cfu / g; the bacteria content in the Trichoderma harzianum powder is 1 billion cfu / g. The preparation method is as follows: crushing monosodium glutamate leftover powder, 1,3-propanediol fermentation waste residue, dried chicken manure and phosphate fertilizer into 100-mesh powder. Then use the disc granulation system to granulate, and screen the fertilizer granules with a particle size of 2mm-4mm. After Trichoderma harzianum, Bacillus subtilis, and Bac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com