Stable methylacryloyl cage type silsesquioxane emulsion with Pickering effect and preparation thereof

A technology of methacryloyloxy cage and silsesquioxane, which is applied in the field of emulsion polymerization preparation, can solve the problems of narrow range of inorganic particles, and achieve the effects of simple post-processing, stable emulsion, and reduced use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

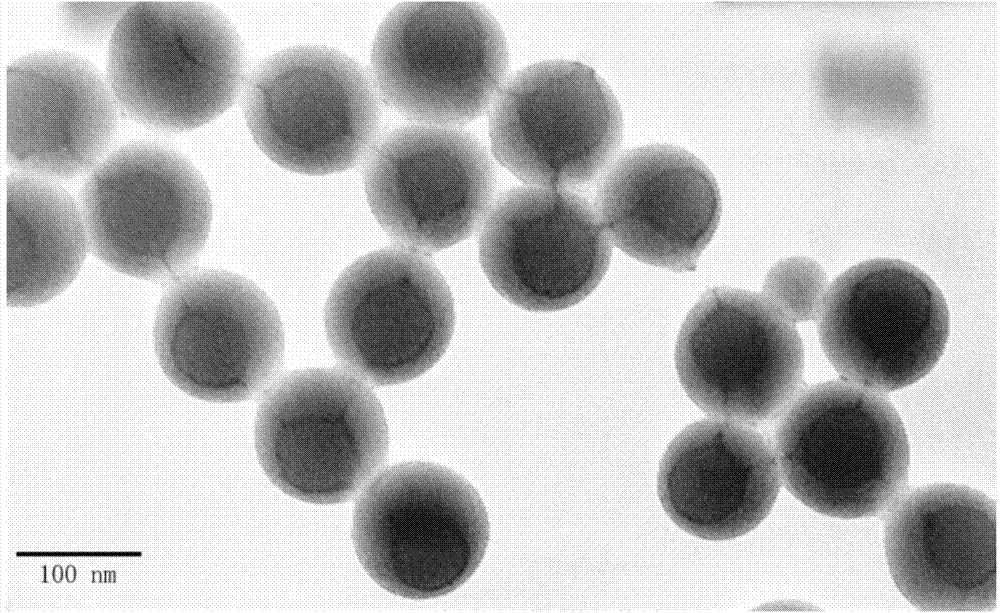

[0038] Example 1: Preparation of MA-POSS Stabilized Emulsion with Pickering Effect

[0039] (1) Preparation of pre-emulsion

[0040] Add 10 g of styrene to the four-necked flask, T 8 -MA-POSS1g, water 20g, sodium dodecyl sulfonate 0.037g, OP-100.018g, 3g sodium bicarbonate solution with mass concentration of 3% to adjust the pH to 7~8. A mechanical stirrer was used to carry out the stirring reaction, the rotating speed was 700 rpm, and the pre-emulsification was stopped after 40 min at normal temperature to obtain a white emulsion.

[0041] (2) Preparation of polymer emulsion by seed emulsion polymerization

[0042] The pre-emulsion obtained in the above steps was transferred to a constant pressure funnel, and about 20% of the remaining in the flask was used as a seed, and an initiator solution, that is, 3 g of a 3% ammonium persulfate (APS) solution, was added, and about 20% of the ammonium persulfate (APS) solution was added to the flask. APS solution. A constant pressur...

Embodiment 2

[0045] Example 2: Preparation of MA-POSS Stabilized Emulsion with Pickering Effect

[0046] (1) Preparation of pre-emulsion

[0047] Add 10 g of styrene to the four-necked flask, T 8 -MA-POSS 2g, water 20g, sodium dodecyl sulfonate 0.028g, OP-100.014g, 4g sodium bicarbonate solution with a mass concentration of 3% to adjust the pH to 7-8. The stirring reaction was carried out with a mechanical stirrer, the rotating speed was 700 rpm, and the temperature was normal. After 40 min, the pre-emulsification was stopped to obtain a white emulsion.

[0048] (2) Preparation of polymer emulsion by seed emulsion polymerization

[0049] The pre-emulsion obtained in the above steps was transferred to a constant pressure funnel, and the remaining about 20% in the flask was used as a seed. A constant pressure funnel was loaded on the four-necked flask, and the pre-emulsion was uniformly added dropwise, and the constant-flow pump was uniformly added dropwise to the ammonium persulfate sol...

Embodiment 3

[0052] Example 3: Preparation of MA-POSS Stabilized Emulsion with Pickering Effect

[0053] (1) Preparation of pre-emulsion

[0054] Add 10 g of styrene to the four-necked flask, T 8 -MA-POSS 3g, water 22g, sodium dodecyl sulfonate 0.017g, OP-100.009g, 4g sodium bicarbonate with a mass concentration of 4% to adjust the pH to 8-9. A mechanical stirrer was used to carry out the stirring reaction, the rotating speed was 700 rpm, and the pre-emulsification was stopped after 40 min at normal temperature to obtain a white emulsion.

[0055] (2) Preparation of polymer emulsion by seed emulsion polymerization

[0056] The pre-emulsion obtained in the above steps was transferred to a constant pressure funnel, and about 30% of the remaining in the flask was used as a seed. A constant pressure funnel was loaded on the four-necked flask, and the pre-emulsion was uniformly added dropwise, and the constant-flow pump was uniformly added dropwise to the ammonium persulfate solution, the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com