Method and device for producing crude antimony by smelting antimony oxide-containing material in smelting furnace

A molten pool smelting technology containing antimony oxide, applied in the field of antimony smelting, can solve the problems of low direct metal recovery rate, low production efficiency, and high labor intensity, and achieve good economic benefits, high production efficiency, and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The method for producing crude antimony by melting in a molten pool containing antimony oxide material in this embodiment specifically includes the following steps:

[0042] In this embodiment, the furnace materials (including antimony oxide-containing materials, anthracite, iron ore, lime, etc.) comprehensive silicate gangue composition: SiO 2 :FeO:CaO=1:1.2:0.6;

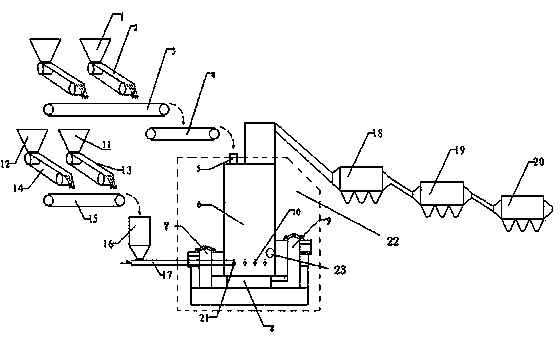

[0043] Crush the anthracite to a particle size of less than 2mm, and measure the coarse antimony trioxide powder, anthracite, hematite, and quicklime according to the mass ratio of 100:20:6:1; the coarse antimony trioxide powder is measured from the silo II11 through batching Belt Ⅱ13 metering, the crushed anthracite powder is metered from silo Ⅲ12 and batching metering belt Ⅲ14, and then transferred to the pressure-feeding pneumatic conveying pump 16 through the transfer belt Ⅱ15. 21 is sprayed into the molten pool melting furnace;

[0044] Iron ore and lime are respectively measured from silo Ⅰ1 through ...

Embodiment 2

[0049] The method of utilizing antimony oxide-containing material molten pool smelting to produce crude antimony in this embodiment is the same as that in embodiment 1, except that:

[0050] The materials (including materials containing antimony oxide, reducing agent, flux iron ore, flux lime, etc.) put into the furnace in this embodiment satisfy the following mass ratio of SiO 2 : FeO: CaO = 1: 1.3: 0.5.

[0051] The antimony oxide ore, anthracite, iron ore, and lime are measured by the electronic belt scale according to the ratio of 100:25:12:5, and then continuously put into the oxygen-enriched side blowing molten pool melting furnace through the feeding port 5; the temperature in the furnace is controlled at 1200 ℃~1300℃, the depth of the molten pool is 1500~1750mm; the oxygen volume ratio of the oxygen-enriched air is 85%; the pressure of the oxygen-enriched air is controlled at 0.05~0.08MPa, and the wind speed is 185m / s; Contains 0.8% antimony.

[0052] The bed capacit...

Embodiment 3

[0054] The method of utilizing antimony oxide-containing material molten pool smelting to produce crude antimony in this embodiment is the same as that in embodiment 1, except that:

[0055] The materials (including materials containing antimony oxide, reducing agent, flux iron ore, flux lime, etc.) put into the furnace in this embodiment satisfy the following mass ratio of SiO 2 : FeO: CaO = 1: 0.8: 0.8.

[0056] The antimony oxide ore, anthracite, iron ore, and lime are measured by the electronic belt scale according to the ratio of 100:12:8:3, and then continuously put into the oxygen-enriched side blowing molten pool melting furnace through the feeding port 5; the temperature in the furnace is controlled at 1200 ℃~1300℃, the depth of the molten pool is 1500~1750mm; the oxygen volume ratio of the oxygen-enriched air is 35%; the pressure of the oxygen-enriched air is controlled at 0.05~0.08MPa, and the wind speed is 150m / s; Contains 0.8% antimony.

[0057] The bed capacity...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com