Bifidobacterium longum microcapsule and preparation method thereof

A technology of bifidobacteria longum and microcapsules, applied in bifidobacteria, food preparation, bacteria used in food preparation, etc., can solve problems such as the decrease in the number of viable bacteria, and achieve longer shelf life, less survival, and tolerance. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

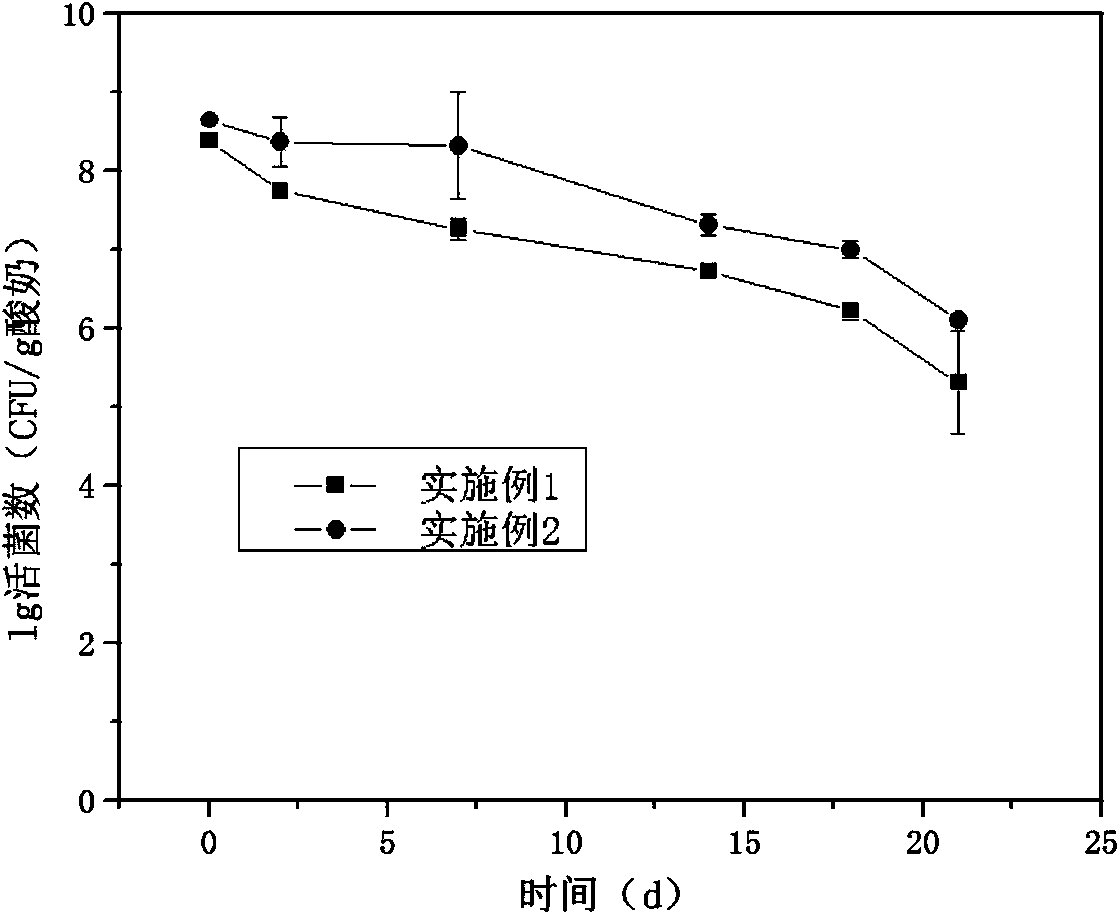

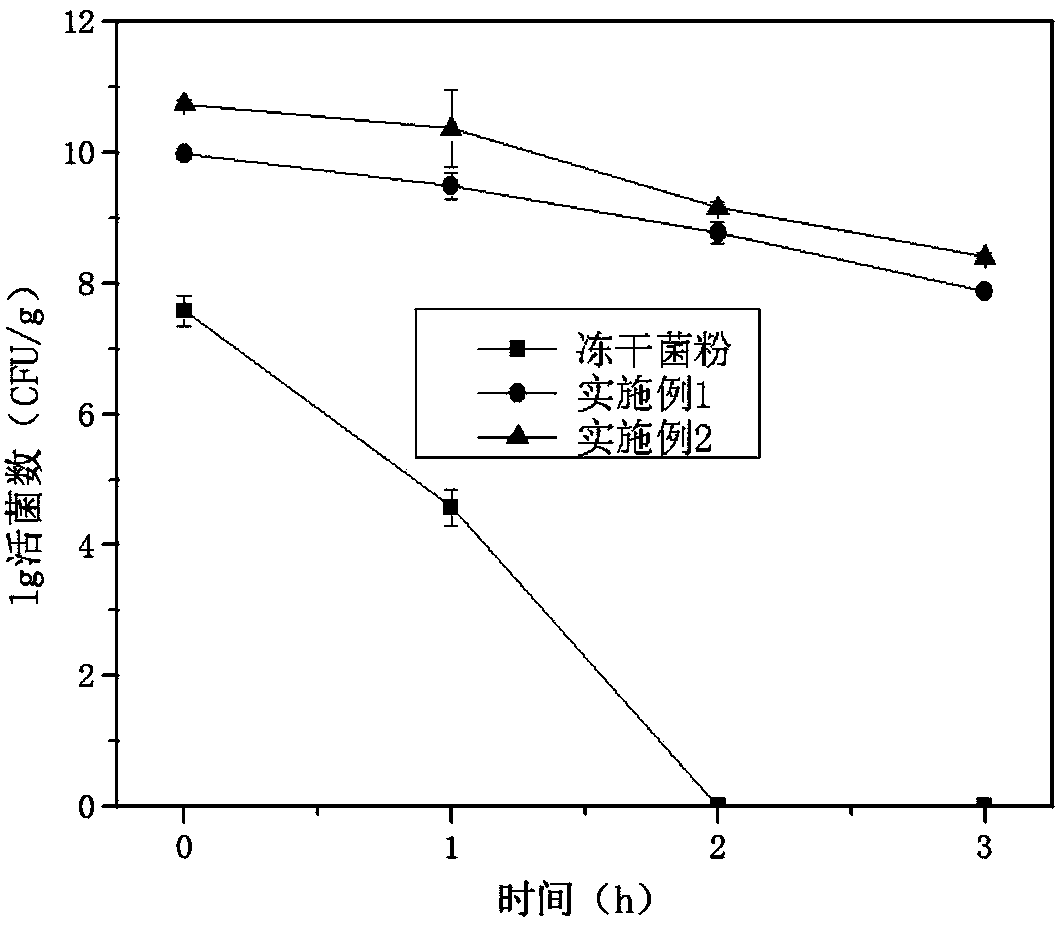

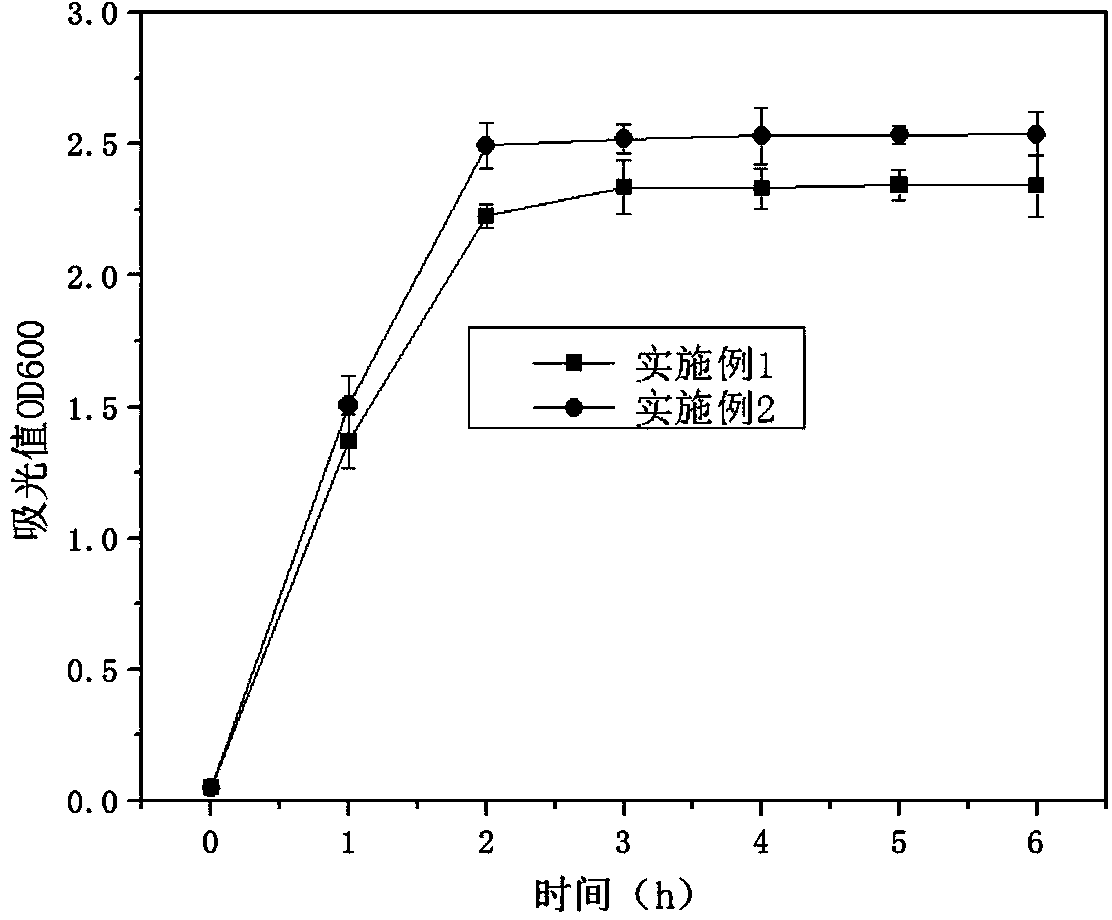

[0043] Example 1 Bifidobacterium longum BBMN68 is used as the core material, and sodium alginate and whey protein are used as the wall material

[0044] (1) Preparation of bacterial strains: In the ultra-clean workbench, inoculate 0.1ml of the frozen Bifidobacterium longum BBMN68 bacterial solution into 10ml of MRS liquid medium, and use an anaerobic tube in a constant temperature and humidity box at 36.5- Cultivate at a temperature of 37.5°C for 12 hours, repeat passage for 2-3 times, and obtain activated Bifidobacterium longum.

[0045] The activated Bifidobacterium longum was inoculated into 250ml of MRS liquid medium at a volume ratio of 0.1%, placed in a constant temperature and humidity chamber, cultivated at a temperature of 36.5-37.5°C for 15h, and centrifuged at 4500rpm for 15min to collect the bacteria. Then the thallus was washed with 0.9% physiological saline, centrifuged at 4500 rpm for 15 min, and washed twice to obtain muddy wet thallus of Bifidobacterium longum...

Embodiment 2

[0052] Example 2 Bifidobacterium longum BBMN68 is used as the core material, and sodium alginate, whey protein and glycerin are used as the wall material

[0053] The polysaccharide solution is prepared by dissolving the polysaccharide in 50wt% glycerin aqueous solution. The mass ratio of glycerin, sodium alginate and whey protein in the final product is 12.5:1:1. Other specific preparation methods are the same as in the above-mentioned Example 1.

Embodiment 3

[0055] The specific preparation method is the same as in Example 2, but sodium alginate is dissolved in 50wt% glycerol aqueous solution, wherein the mass ratio of glycerol to sodium alginate is 25:1, and it is mixed with 8wt% whey protein, and the final product is The mass ratio of glycerin, whey protein and chitosan is 25:5:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com