Preparation methods and applications of graphene oxide composite and nickel oxide supported graphene composite

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

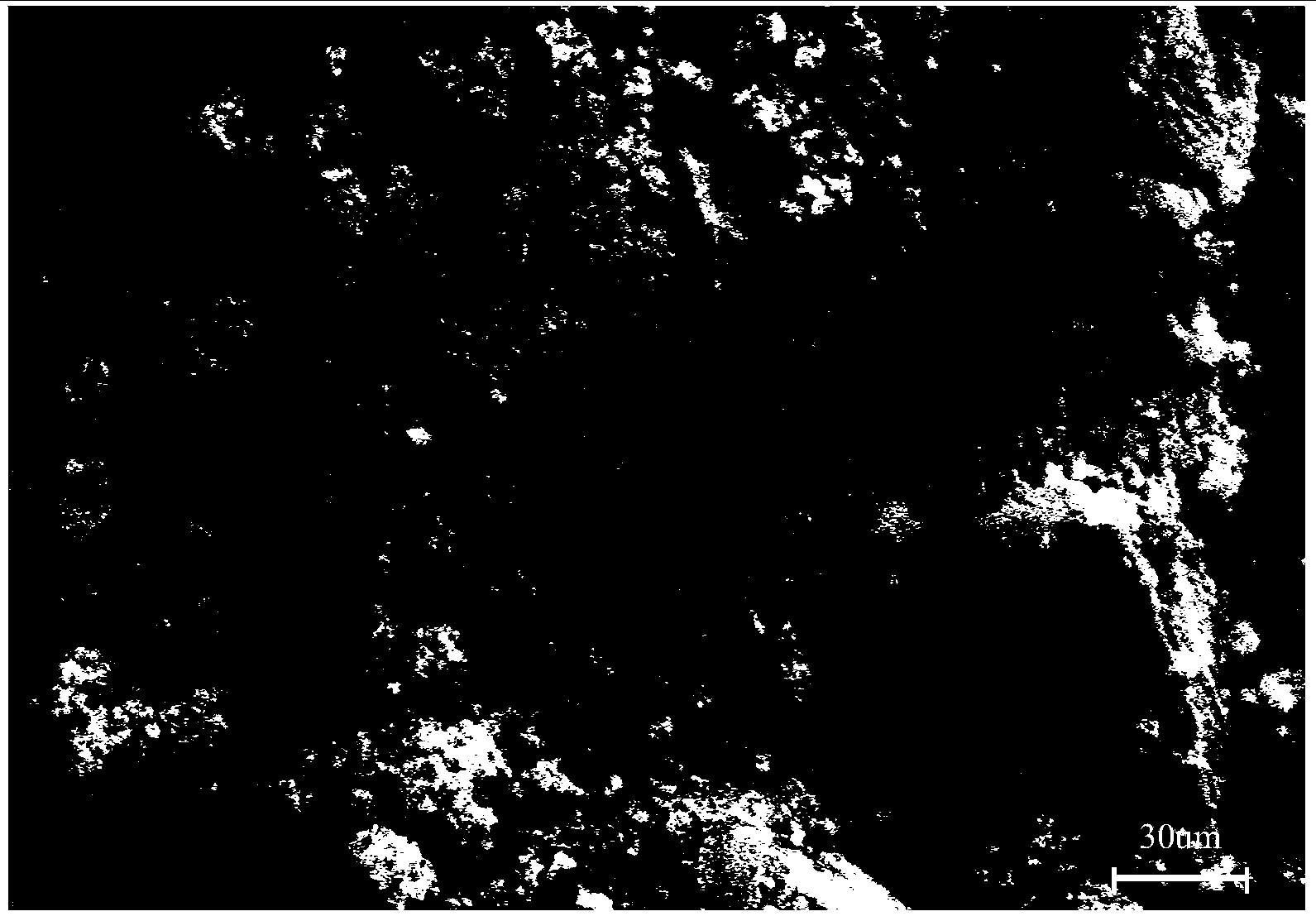

Image

Examples

Embodiment 1

[0045] The preparation method of the composite graphene oxide adsorbent of the present embodiment may further comprise the steps:

[0046] (1) Disperse graphene oxide in water, and obtain a graphene oxide suspension with a concentration of 4 mg / mL after ultrasonic dispersion for 30 minutes;

[0047] The graphene oxide of this example was synthesized by the modified Hummers method, and the specific steps were as follows: slowly add 10 g of graphite and 5 g of sodium nitrate into a flask containing 230 mL of concentrated sulfuric acid, and stir in an ice-water mixture. After 30 min, slowly add 30 g of potassium permanganate, during the stirring process, control the reaction temperature to always be less than 15°C, and keep it for 90 min; transfer the reaction system to a constant temperature water bath at 35°C, keep the reaction temperature at 35°C, and stir for 30 min; Add 460mL of deionized water, control the reaction temperature at 90°C, and stir for 30 min; then add 100mL of...

Embodiment 2

[0059] The preparation method of the composite graphene oxide adsorbent of the present embodiment may further comprise the steps:

[0060] (1) Disperse graphene oxide (prepared by the preparation method in Example 1) in water, and obtain a graphene oxide suspension with a concentration of 6 mg / mL after ultrasonic dispersion for 60 minutes;

[0061] (2) adding camphor wood chips and carboxymethyl cellulose to the graphene oxide suspension obtained in step (1); wherein the mass ratio of graphene oxide, camphor wood chips and carboxymethyl cellulose is 2:1:6, Stir well, react at 50°C for 5 hours, and obtain a reaction solution after complete reaction;

[0062] (3) The mixture obtained after step (2) is subjected to suction filtration, washing and freeze-drying to obtain a composite graphene oxide adsorbent.

[0063] The preparation method of the nickel oxide-supported graphene composite of the present embodiment may further comprise the steps:

[0064] (1) Add the composite gra...

Embodiment 3

[0069] The preparation method of the composite graphene oxide adsorbent of the present embodiment may further comprise the steps:

[0070] (1) Disperse graphene oxide (prepared by the preparation method in Example 1) in water, and obtain a graphene oxide suspension with a concentration of 5 mg / mL after ultrasonic dispersion for 45 minutes;

[0071] (2) adding camphor wood chips and carboxymethyl cellulose to the graphene oxide suspension obtained in step (1); wherein the mass ratio of graphene oxide, camphor wood chips and carboxymethyl cellulose is 2:1:5, Stir well, react at 52°C for 4 hours, and obtain a reaction solution after complete reaction;

[0072] 3) The mixture obtained after step (2) is subjected to suction filtration, washing and freeze-drying to obtain a composite graphene oxide adsorbent.

[0073] The preparation method of the nickel oxide-supported graphene composite of the present embodiment may further comprise the steps:

[0074] (1) Add the composite grap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Layer spacing | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com