Zero discharge treatment process of saline sewage produced by refining

A treatment process and zero-emission technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as reducing fresh steam consumption, and meet long-term operation and failure The effect of low efficiency and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

[0020] The zero-discharge treatment process for refinery salty sewage provided by the present invention includes the following three steps:

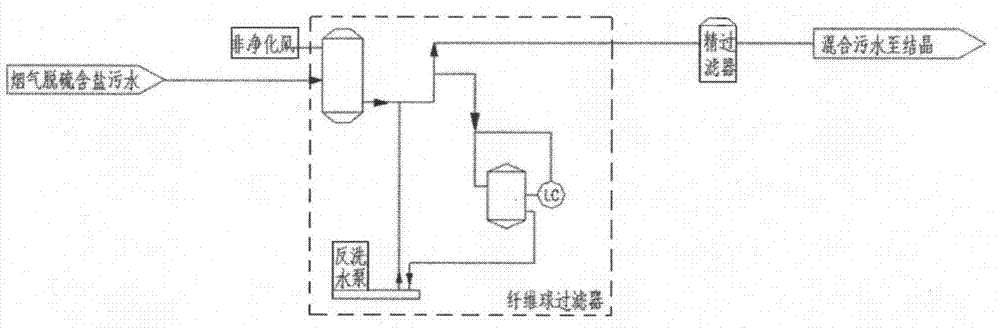

[0021] Step 1: Combine figure 1 , the salty sewage from the flue gas desulfurization PTU (waste liquid treatment unit), the salt contained is sodium sulfite or ammonium sulfate, the mass concentration is 7.5% to 20%, and most of the solid particles are first filtered through a fiber filter , and then pass through the fine filter for secondary fine filtration, the filtration accuracy is 1-15 microns, and the solid particles in the filtered water are less than 2mg / L.

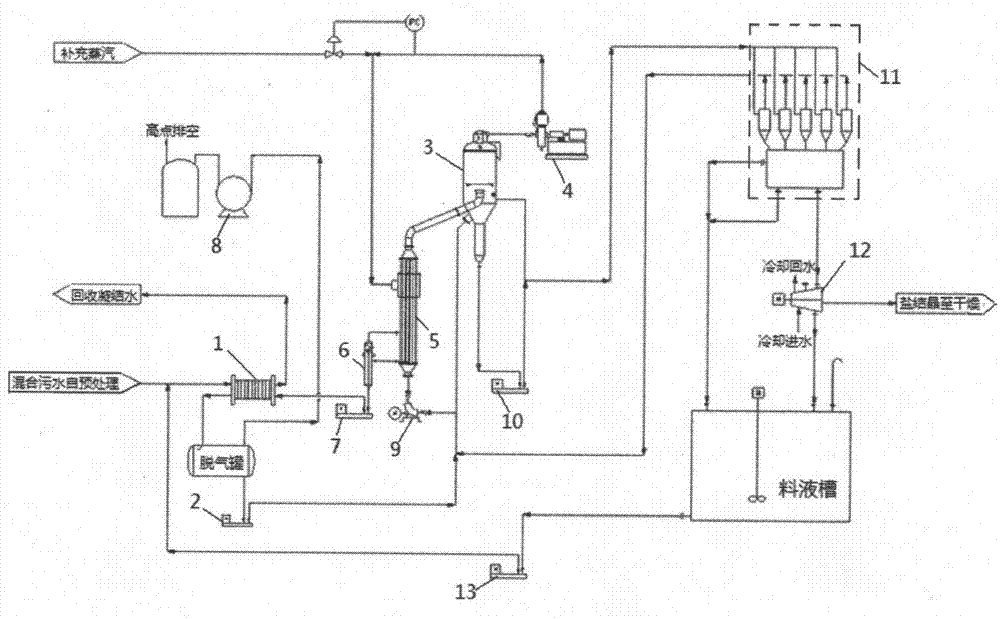

[0022] Step 2: Combine figure 2 , the finely filtered salty sewage passes through the plate heat exchanger 1 to exchange heat with the recovered condensed water, enters the degassing tank, uses vacuum degassing to remove the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com