Mn-doped sodium bismuth titanate-potassium bismuth titanate-strontium titanate ternary series piezoelectric film material and preparation method thereof

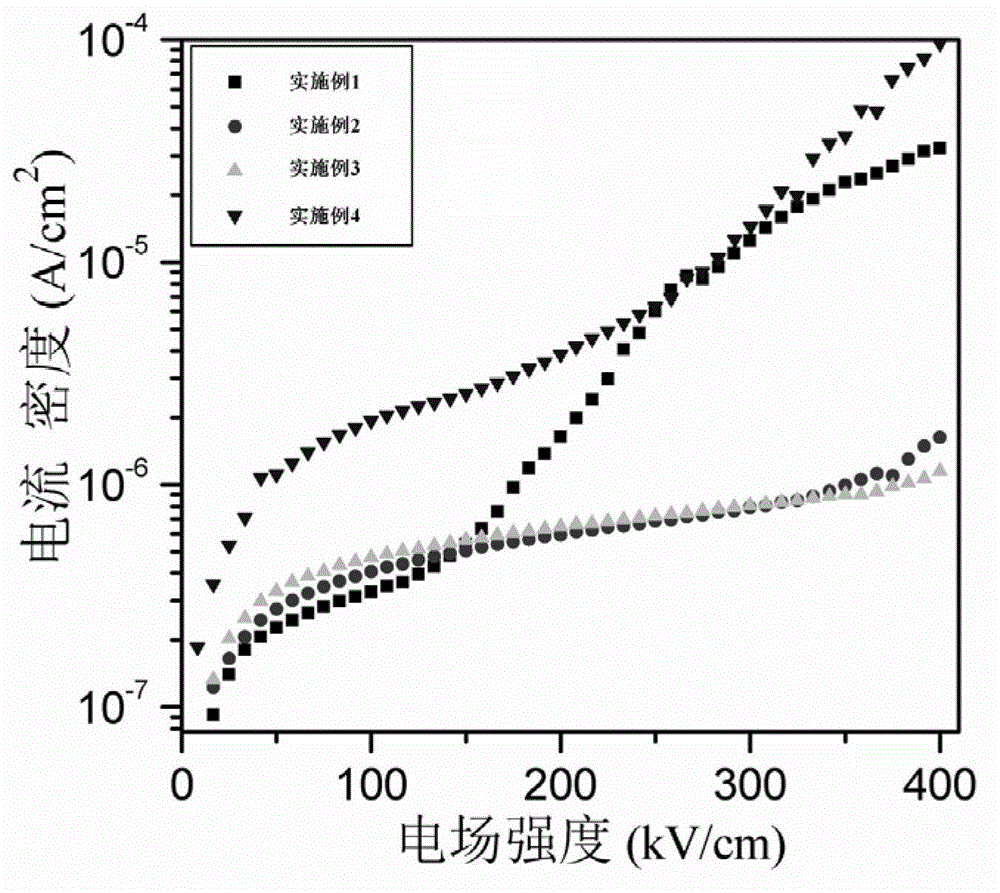

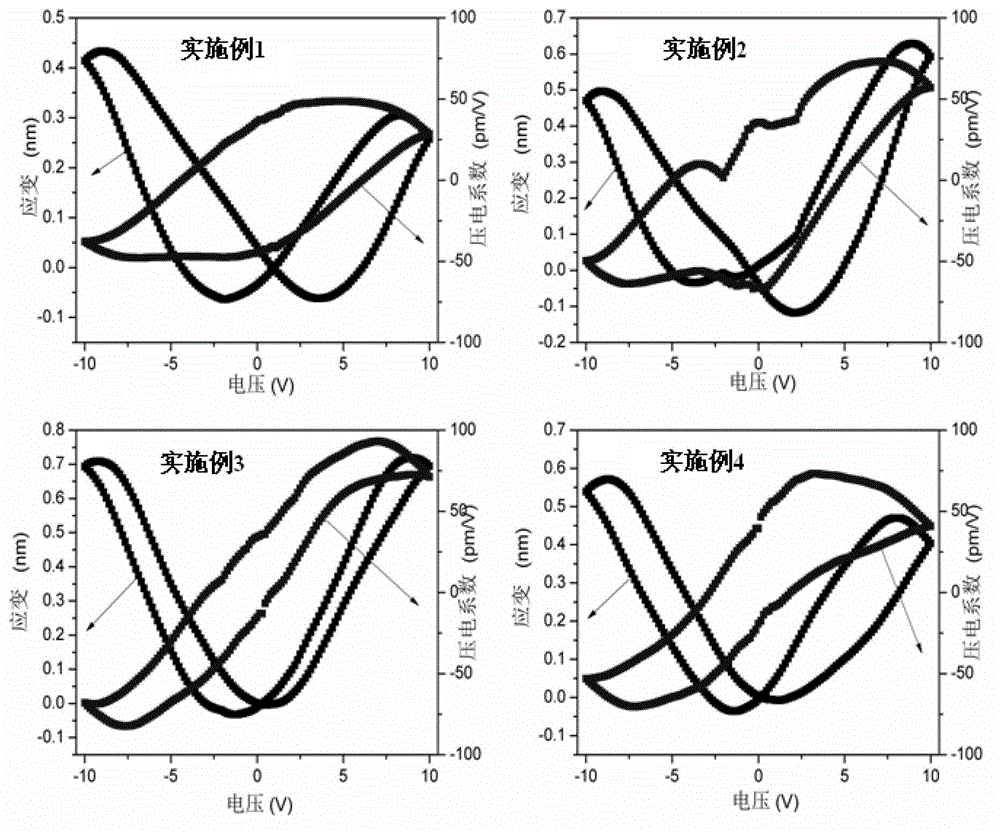

A bismuth potassium titanate and piezoelectric thin film technology is applied in the field of bismuth titanate sodium-bismuth potassium titanate-strontium titanate ternary piezoelectric thin film material and its preparation to reduce leakage current, increase polarization voltage, Effect of performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] (2) Preparation of thin film: the precursor solution C prepared in step (1) was coated on Pt / Ti / SiO by spin coating 2 / Si substrate:

[0031] a) Pt / Ti / SiO 2 / Si substrate is pretreated at 300-500°C for 10-20 minutes.

[0032] b) Spin-coat precursor solution C on the substrate obtained after step a) at a rotation speed of 3000 rpm for 20 seconds.

[0033] c) Treat the film obtained after step b) in a tube furnace in sequence at 100-200°C for 2-3 minutes, and at 300-400°C for 5-10 minutes, repeat this step to obtain a film of required thickness, and finally Annealing at ~800° C. for 20 to 40 minutes to prepare Mn-doped bismuth titanate sodium-bismuth potassium titanate-strontium titanate ternary piezoelectric film material.

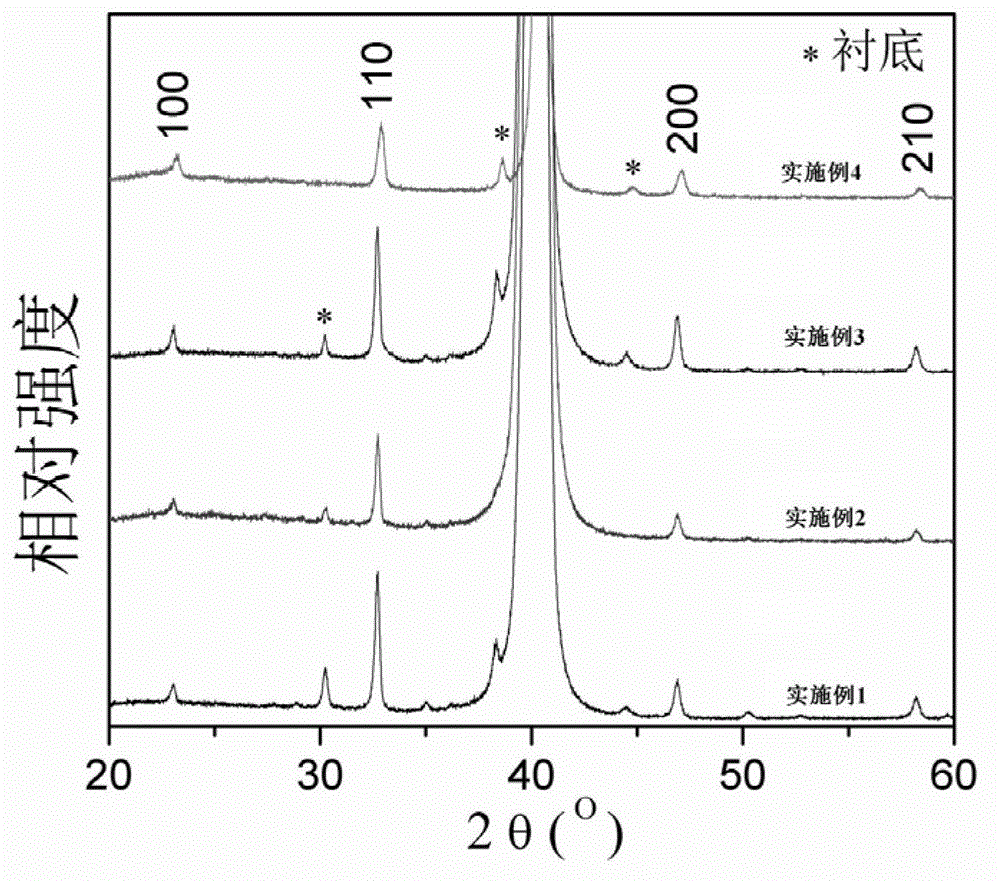

Embodiment 1

[0036] Preparation of bismuth titanate sodium-bismuth potassium titanate-strontium titanate thin film Mn doping amount is 0.

[0037] a, according to the general chemical formula (0.8Bi 1 / 2 Na 1 / 2 TiO 3 -0.2Bi 1 / 2 K 1 / 2 )TiO 3 Weigh raw materials, dissolve bismuth nitrate, sodium acetate, potassium acetate, in acetic acid, stir and heat to boiling for 15-30 minutes to prepare solution ①; use acetylacetone as complexing agent to dissolve titanium isopropoxide in ethyl alcohol Glycol ether was stirred at 50-70°C for 60 minutes to prepare solution ②; finally, solution ② was poured into solution ①, and the concentration of the solution was controlled at 0.3M, and stirred at 50-70°C for 120 minutes to prepare precursor solution A.

[0038] b. According to the general chemical formula SrTiO 3 The stoichiometric ratio of the raw material strontium acetate was weighed and stirred and heated to boiling for 15-30 minutes to obtain a solution ③, titanium isopropoxide was dissolved ...

Embodiment 2

[0045] The bismuth titanate sodium-bismuth potassium titanate-strontium titanate thin film was prepared with a Mn doping amount of 0.2%.

[0046] a, according to the general chemical formula (0.8Bi 1 / 2 Na 1 / 2 TiO 3 -0.2Bi 1 / 2 K 1 / 2 )T1O 3 The stoichiometric ratio of +0.2mol% Mn weighs the raw materials, dissolves bismuth nitrate, sodium acetate, potassium acetate, manganese acetate, in acetic acid, stirs and heats to boiling for 15-30 minutes to prepare the solution ①; use acetylacetone as complexing agent Dissolve titanium isopropoxide in ethylene glycol ether and stir at 50-70°C for 60 minutes to prepare solution ②; finally, pour solution ② into solution ①, control the concentration of the solution at 0.3M, and stir at 50-70°C for 120 minutes Prepare precursor solution A.

[0047] b. According to the general chemical formula SrTiO 3 The stoichiometric ratio of the raw material strontium acetate was weighed and stirred and heated to boiling for 15-30 minutes to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Leakage current | aaaaa | aaaaa |

| Piezoelectric coefficient | aaaaa | aaaaa |

| Piezoelectric coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com