Preparation method of HfC-SiC modified carbon/carbon composite material

A carbon composite material and modification technology, applied in the field of preparation of HfC-SiC modified carbon/carbon composite material, can solve the problems of carbon fiber damage, weak bonding strength, serious carbon fiber damage, etc., and improve wettability. , improve the density, improve the effect of anti-ablation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

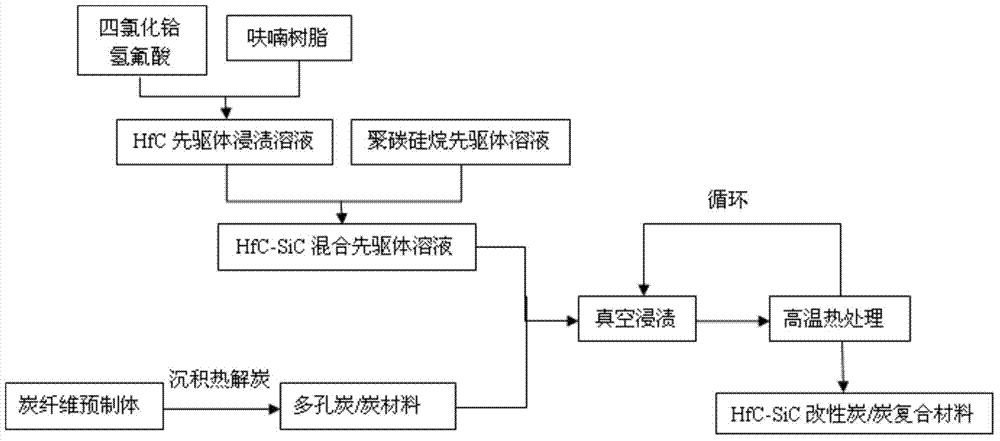

[0022] This example is a method for preparing a modified carbon / carbon composite material mixed with HfC-SiC.

[0023] Step 1, cleaning of the carbon fiber prefabricated body. After cleaning the carbon fiber prefabricated body with absolute ethanol for 10 minutes, put it into an oven to dry for later use. The drying temperature is 60°C.

[0024] Step 2, preparation of porous carbon / carbon composites. The carbon fiber preform was placed in a thermal gradient chemical vapor deposition furnace, with natural gas as the precursor, the deposition temperature was 900 °C, and the deposition time was 3 h. After the deposition, graphitization treatment is performed at 2300°C to obtain a porous carbon / carbon composite material.

[0025] Step 3, introduction of HfC and SiC. The specific process is:

[0026] 1) Weigh hafnium tetrachloride, hydrofluoric acid and furan resin respectively according to the mass ratio of 5:1:4, and first mix hafnium tetrachloride and hydrofluoric acid to p...

Embodiment 2

[0032] Step 1, cleaning of the carbon fiber prefabricated body. After cleaning the carbon fiber prefabricated body with absolute ethanol for 20 minutes, put it into an oven to dry for later use. The drying temperature is 75°C.

[0033] Step 2, preparation of porous carbon / carbon composites. The carbon fiber preform was placed in a thermal gradient chemical vapor deposition furnace, with natural gas as the precursor, the deposition temperature was 1050 °C, and the deposition time was 4.5 h. After the deposition, a graphitization treatment at 2400°C is carried out to obtain a porous carbon / carbon composite material.

[0034] Step 3, introduction of HfC and SiC. The specific process is:

[0035]1) Weigh hafnium tetrachloride, hydrofluoric acid and furan resin respectively according to the mass ratio of 5:1:4, and first mix hafnium tetrachloride and hydrofluoric acid to prepare an acidic solution containing hafnium. Hafnium hafnium powder was 20g, hydrofluoric acid was 4g, fu...

Embodiment 3

[0046] Step 1, cleaning of the carbon fiber preform. After the carbon fiber prefabricated body was cleaned with absolute ethanol for 30 minutes, it was dried in an oven for later use. The drying temperature is 85°C.

[0047] Step 2, preparation of porous carbon / carbon composites. The carbon fiber preform was placed in a thermal gradient chemical vapor deposition furnace, with natural gas as the precursor, the deposition temperature was 1200 °C, and the deposition time was 6 h. After the deposition, a graphitization treatment at 2500°C is carried out to obtain a porous carbon / carbon composite material.

[0048] Step 3, introduction of HfC and SiC. The specific process is:

[0049] 1) Weigh hafnium tetrachloride, hydrofluoric acid and furan resin respectively according to the mass ratio of 5:1:4, and first mix hafnium tetrachloride and hydrofluoric acid to prepare an acidic solution containing hafnium. Hafnium hafnium powder was 25g, hydrofluoric acid was 5, furan resin was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com