A kind of triphenoxy biscyclopentadienyl titanium catalyst and its preparation method and application

A technology of triphenoxydicyclopentadiene and biphenylbistetramethylcyclopentadiene, which is applied in the field of polymer polymerization catalysts, can solve the problems of loss of active ingredients, cumbersome preparation steps, and high consumption of cocatalysts, and achieves Wide molecular weight distribution, simple loading process, and reduced usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

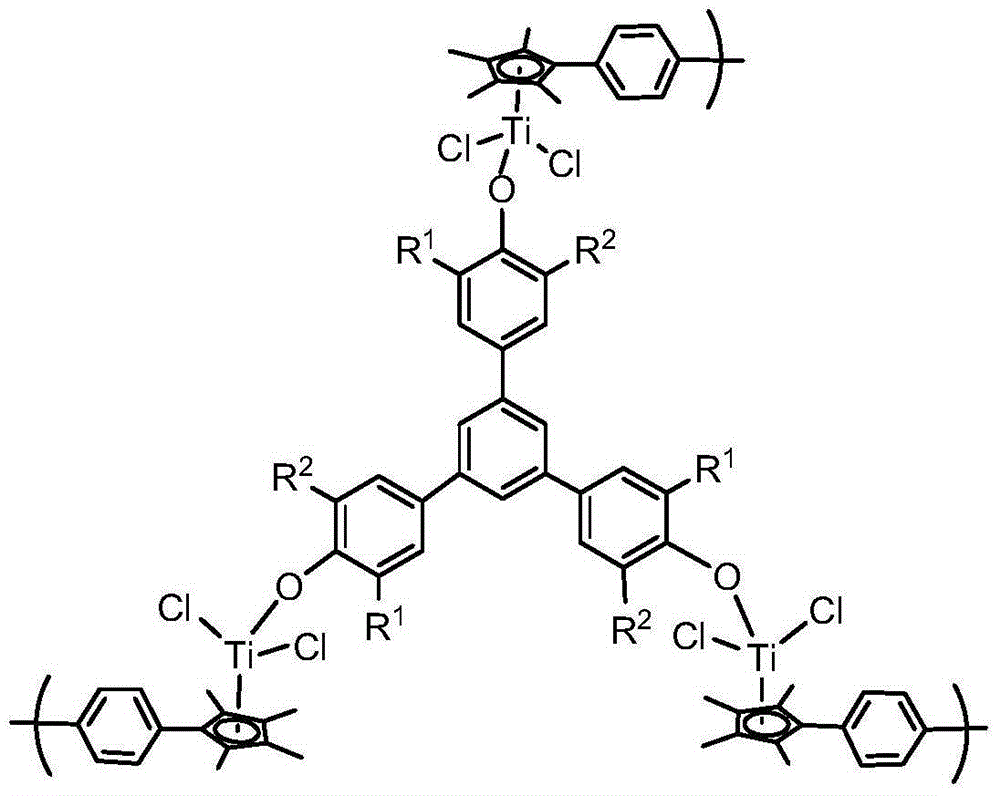

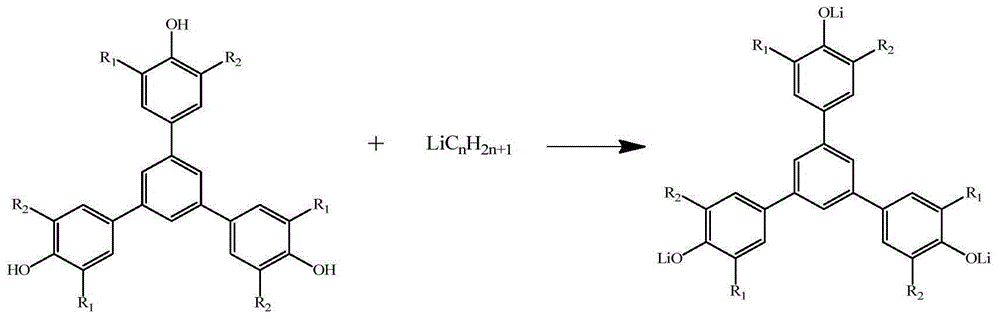

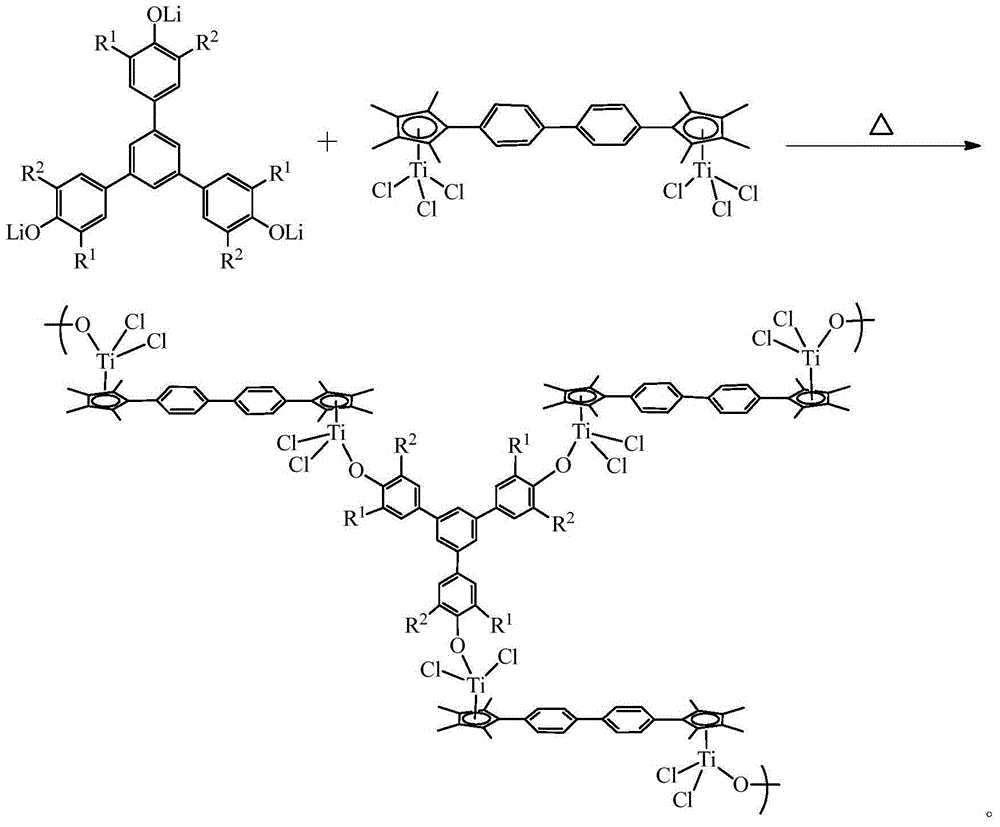

[0027] The preparation of embodiment 1 triphenoxy biscyclopentadienyl titanium catalyst Ti1

[0028] At 0°C, 0.50 mmol of triisopropyl substituted triglucinol, that is, R in it 1 Substituents are isopropyl, R 2 Phenylglucinol with a substituent of H phenyl bridge is added to a reaction ampoule filled with toluene solvent, after stirring evenly, 1.5 mmol of butyllithium is added, and the reaction is carried out for 3 hours. The whole reaction process needs to be carried out under the protection of nitrogen. ; Then, after the temperature was gradually raised to room temperature, 0.75 mmol of biphenyl bis-tetramethylcyclopentadienyl titanium trichloride was added and heated to 80°C for 8 hours of reaction. The solvent of the reaction product was vacuum-dried, washed with toluene and filtered to obtain an orange solid powder. The yield was 58%. The elemental analysis results are: C: 65.61, H: 7.24 (%).

Embodiment 2 3

[0029] The preparation of embodiment 2 triphenoxy biscyclopentadienyl titanium catalyst Ti1

[0030] At -78°C, add 0.50 mmol of triisopropyl-substituted triglucinol to a reaction ampoule filled with toluene solvent, stir well, then add 1.5 mmol of butyllithium and react for 24 hours. The entire reaction The process needs to be carried out under nitrogen protection; then, after the temperature is gradually raised to room temperature, 0.75 mmol of biphenyl bis-tetramethylcyclopentadienyl titanium trichloride is added and heated to 50° C. for 8 hours of reaction. The solvent of the reaction product was vacuum-dried, washed with toluene and filtered to obtain an orange solid powder. The yield was 45%. The elemental analysis results are: C: 65.51, H: 7.19 (%). It has the same structure as the triphenoxybiscyclopentadienyl titanium catalyst Ti1 prepared in Example 1.

Embodiment 3

[0031] The preparation of embodiment 3 triphenoxy biscyclopentadienyl titanium catalyst Ti2

[0032] At -20°C, 0.50 mmol of tri-tert-butyl substituted triglucinol, that is, the R 1 Substituents are tert-butyl, R 2 Phenylglucinol with a substituent of H phenyl bridge is added to a reaction ampoule filled with toluene solvent, after stirring evenly, 1.5 mmol of butyl lithium is added, and stirring is continued for 3 hours. The whole reaction process needs to be under the protection of nitrogen. Then, after the temperature was gradually raised to room temperature, 0.75 mmol of biphenylbistetramethylcyclopentadienyl titanium trichloride was added and heated to 80°C for 8 hours of reaction. The solvent of the reaction product was vacuum-dried, washed with toluene and filtered to obtain an orange-red solid powder with a yield of 64%. The elemental analysis results are: C: 66.91, H: 6.79 (%).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com