Application of carbon microsphere solid acid formed by one-step fructose hydrothermal synthesis to catalyzing hydrolysis of cellulose

A sugar-based carbon microsphere, cellulose technology, applied in the direction of physical/chemical process catalyst, application, sugar production, etc., can solve the problems of pollution, a large amount of waste gas environment, etc., and achieves simple process, high reducing sugar yield, high yield high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

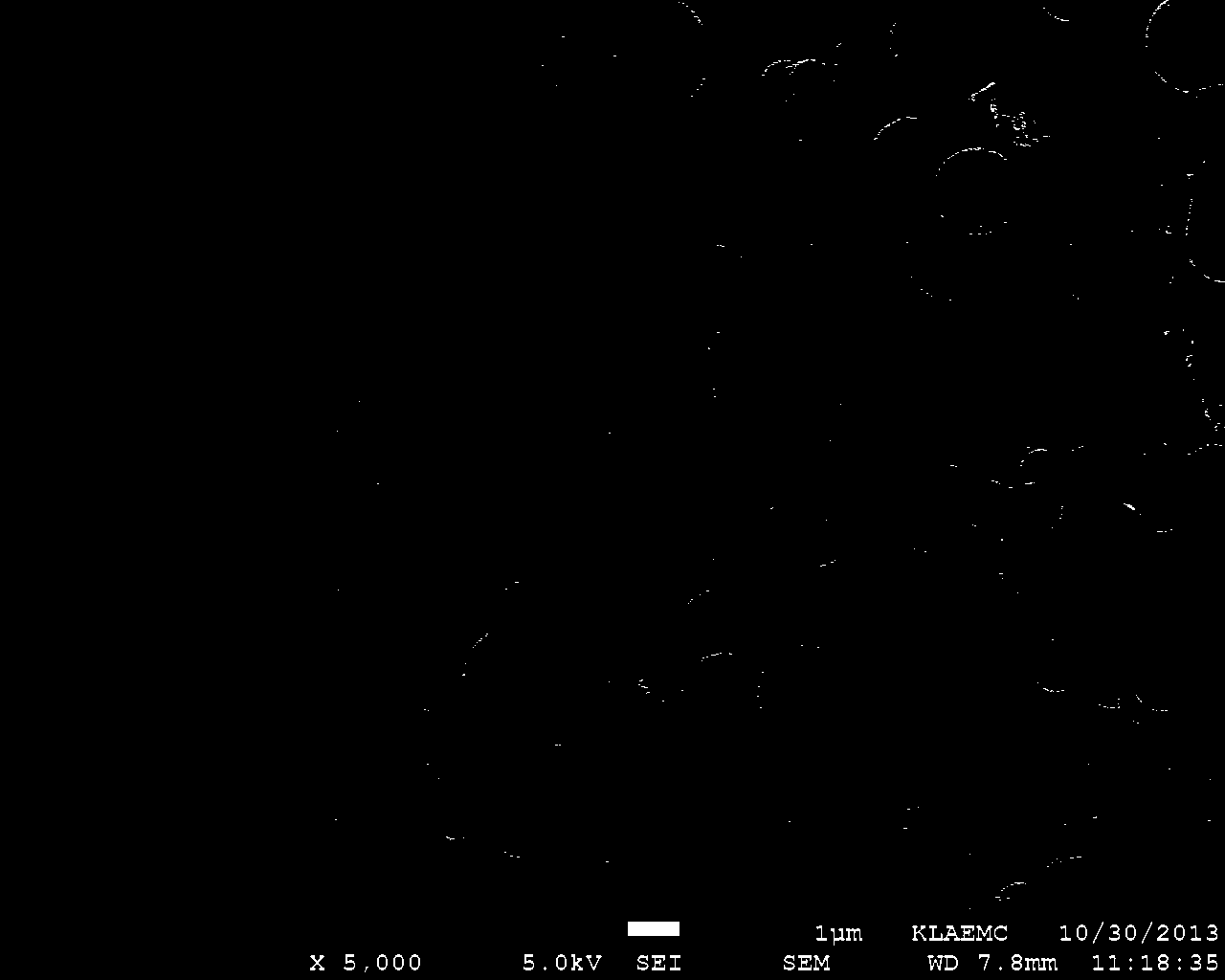

[0028] Embodiment 1, Preparation and Characterization of the Invented Catalyst:

[0029] The preparation process of the carbon microsphere solid acid catalyst is summarized as follows: 10 g of fructose, 5 g of sulfo-salicylic acid and 60 ml of distilled water were successively added under magnetic stirring, and the stirring was continued for 30 min. Then the mixed solution was transferred into a 100 ml stainless steel autoclave lined with polytetrafluoroethylene, sealed and heated to 150°C for 4 hours, and stirred at a speed of 1000 rpm. After the reaction, the reactor was cooled to room temperature. The resulting black powder was alternately washed with distilled water and ethanol several times (ten times in total, 6 times with water and 4 times with alcohol), and dried at 80°C for 12 hours to remove all the water to obtain a carbon microsphere solid acid catalyst. The catalyst is characterized by SEM, FT-IR, XRD and elemental analysis, which proves that it is a carb...

Embodiment 2

[0031] Embodiment 2, Preparation and Characterization of the Invented Catalyst:

[0032] The preparation process of the carbon microsphere solid acid catalyst is summarized as follows: 10 g of fructose, 10 g of sulfo-salicylic acid and 60 ml of distilled water were successively added under magnetic stirring, and the stirring was continued for 30 min. Then the mixed solution was transferred into a 100 ml stainless steel autoclave lined with polytetrafluoroethylene, sealed and heated to 150°C for 4 hours, and stirred at a speed of 1000 rpm. After the reaction, the reactor was cooled to room temperature. The resulting black powder was alternately washed with distilled water and ethanol several times (ten times in total, 6 times with water and 4 times with alcohol), and dried at 80°C for 12 hours to remove all the water to obtain a carbon microsphere solid acid catalyst. The catalyst is characterized by SEM, FT-IR, XRD and elemental analysis, which proves that it is a ca...

Embodiment 3

[0033] Embodiment 3, New catalytic process for cellulose hydrolysis:

[0034] Add 0.05 g of cellulose and 1 g of 1-butyl-3-methylimidazolium chloride salt ionic liquid into a 10 ml reaction kettle, at 80 o Under C, the cellulose is dissolved, then add 0.01 g of water, 0.05 g of the catalyst synthesized in the present invention, and heat to 130 °C in a sealed state. o C, reacted for 90 min, and then rapidly cooled in an ice-water bath; the reaction solution was taken out and diluted, and the yield of reducing sugar was measured to be 62% by the 3,5-dinitrosalicylic acid method (DNS).

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com