Graphene preparation method

A graphene and graphite intercalation technology, applied in the technical field of preparation methods, can solve the problems of difficult preparation, long stripping time, high cost, etc., achieve short expansion implementation time, low waste liquid treatment cost, and prevent a small amount of oxidation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

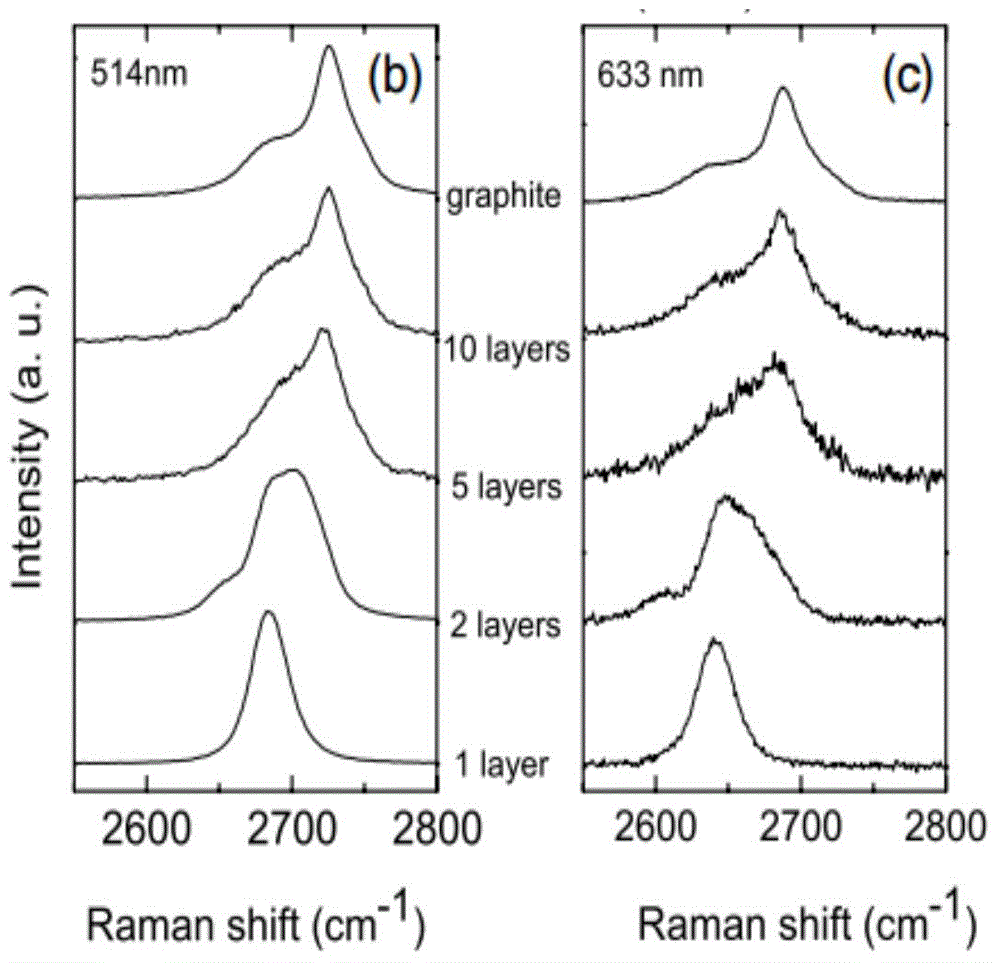

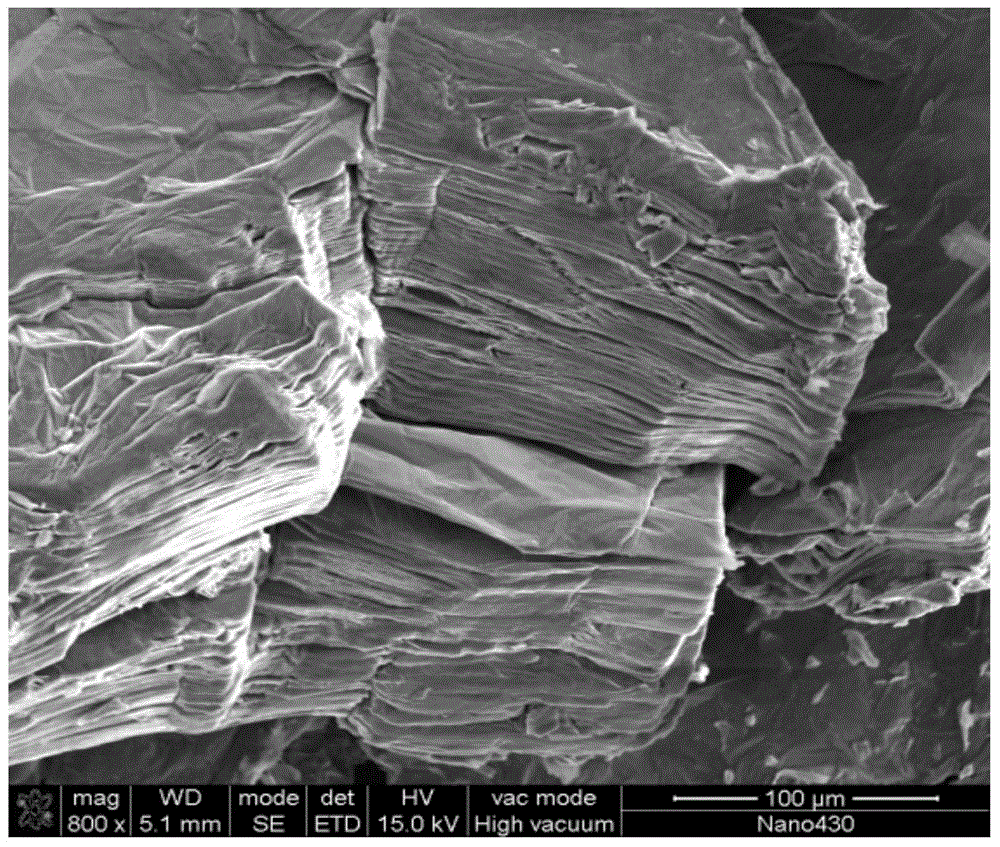

Method used

Image

Examples

Embodiment 1

[0029] Put 1g of the second-order graphite intercalation compound with bromine as the intercalation agent in a 300ml beaker, add 50ml of 5wt% sodium borohydride solution, and let it stand for 3 minutes to obtain highly expanded worm graphite floating on the liquid surface. After filtering and washing the worm graphite with dilute sulfuric acid for 3 times, add 1L of ethanol solution (the volume ratio of ethanol to water is 1:4), and oscillate ultrasonically for 3 hours to obtain a graphene dispersion solution. The yield is about 93%, and graphene powder can be obtained after one day of freeze-drying. The number of graphene layers obtained is 2-5 layers, and the conductivity is 3×10 5 S / m.

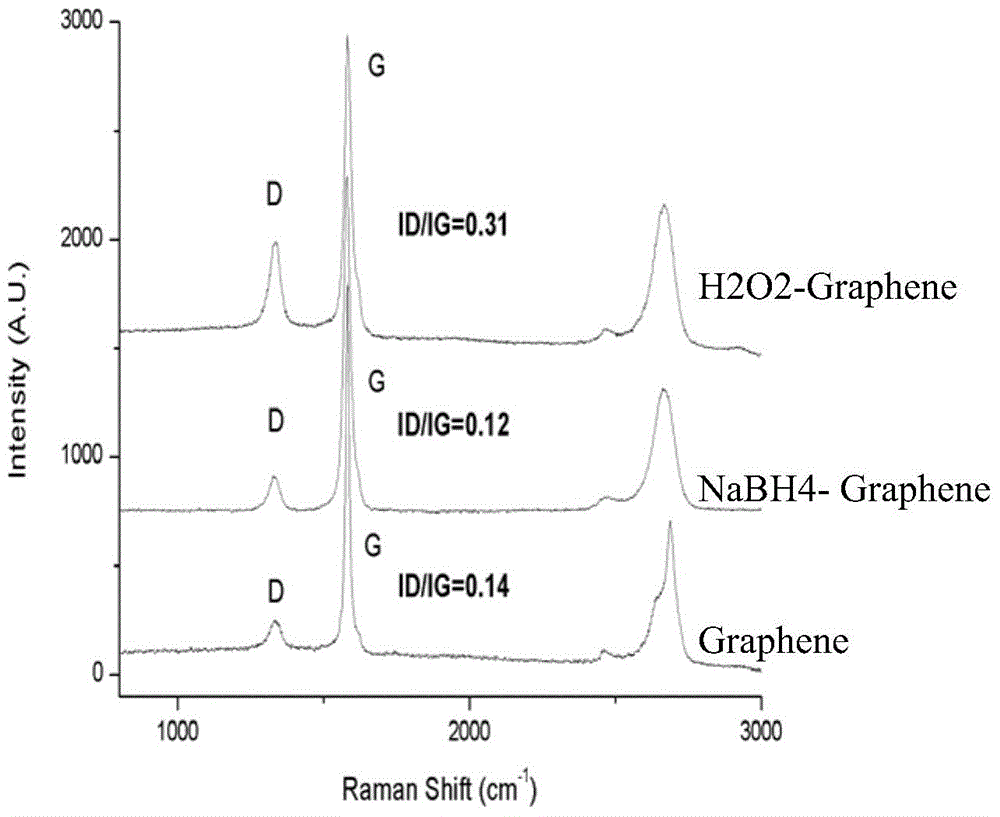

[0030] Conduct electrical performance comparison experiments under the same conditions

[0031] The same reaction amount of graphene intercalation compound and the same instrument were used for determination. The results show that the electrical performance of the hydrogen peroxide syste...

Embodiment 2

[0033] Put 2g of the first-order graphite intercalation compound with ferric chloride as the intercalation agent in a 500ml beaker, add 80ml of 8wt% sodium borohydride solution, and let it stand for 2 minutes to obtain highly expanded worm graphite floating on the liquid surface. After the worm graphite was filtered and washed with dilute sulfuric acid for 3 times, it was added to 1L of 1wt% PVP ethanol solution, and ultrasonically oscillated for 1 hour to obtain a graphene dispersion solution. A small amount of the upper layer was removed to obtain fully ultrasonically expanded graphite, and the yield was about 76%. %, graphene powder can be obtained after freeze-drying for one day. The number of graphene layers obtained is 1-5 layers, and the conductivity is 3×10 5 S / m.

[0034] Conduct electrical performance comparison experiments under the same conditions

[0035] The same reaction amount of graphene intercalation compound and the same instrument were used for determinat...

Embodiment 3

[0039] Add 1.5g of a first-order graphite intercalation compound using zinc chloride as an intercalation agent to a 500ml beaker, add 60ml of lithium borohydride solution with a concentration of 7wt%, and let it stand for 1min to obtain highly expanded worm graphite floating on the liquid surface . After the worm graphite was filtered and washed with dilute hydrochloric acid for 3 times, it was added to 500ml concentration of 2wt%PVP aqueous solution, and ultrasonically oscillated for 2h to obtain a graphene sheet dispersion solution. The upper layer of insufficient ultrasonically expanded graphite was removed, and the yield was about 84%. Graphene powder can be obtained after freeze-drying for one day. The number of graphene layers obtained is 1-5 layers, and the conductivity is 3×10 5 S / m.

[0040] Conduct electrical performance comparison experiments under the same conditions

[0041] The same reaction amount of graphene intercalation compound and the same instrument wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com