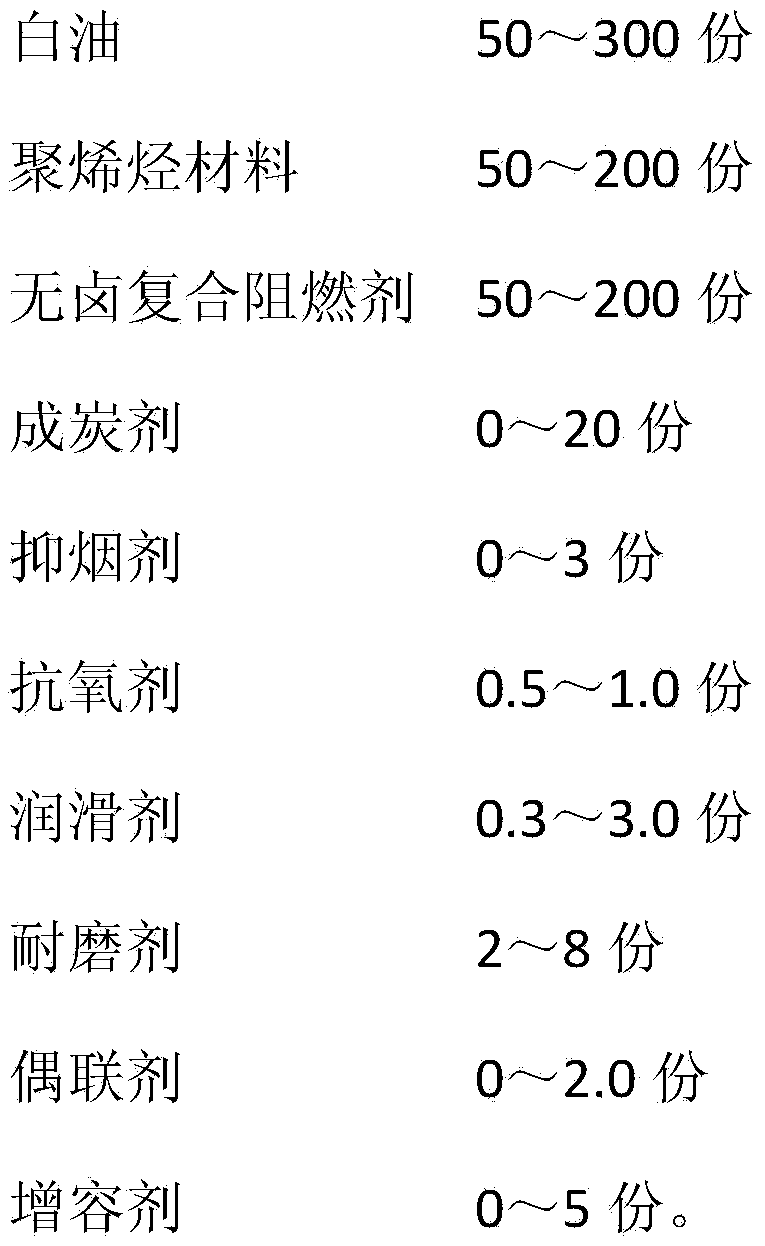

Charging wire material for electric vehicles and preparation method thereof

A technology for electric vehicles and electric wires, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve the problems that are not fully soft and easy to curl, surface wear-resistant processing, recyclable, fire hazards, etc., to avoid The effect of excessive melt viscosity, avoiding reinvestment, moderate price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

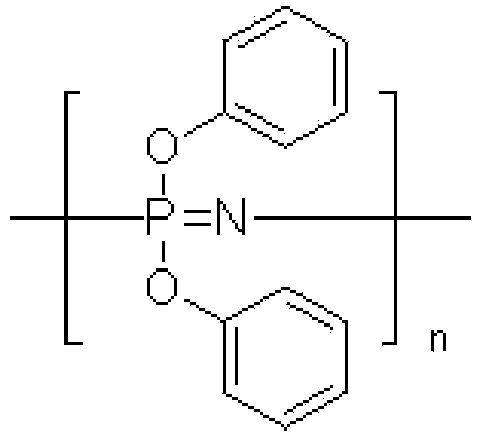

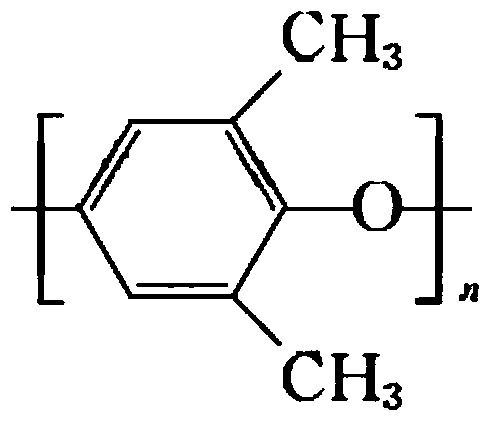

[0060] Example 1: N250 white oil-extended SEBS-G1654 and PP-R370Y are used to form a TPE-S substrate, and a composite system composed of hexaphenoxy cyclotriphosphazene and organically modified MDH H7C / 2 is flame retardant The ratio of the above two flame retardants is 1:1, the PPO-S201A of Japan's Asahi Kasei company is used as the char-forming agent, and the silane-modified nano-SiO2 is used as the anti-wear agent. The other components are detailed in the examples in Table 2. 1 in. From the test results of Example 1 in Table 4, it can be found that the prepared flame-retardant composite material and extruded wire have good mechanical properties and flame-retardant properties, the wire tensile strength is 16.5Mpa, the elongation at break is 413%, and UL94 vertical burning The test result is V-0, and the UL1581 test result is VW-1. The retention rate of the tensile strength of the wire after 168 hours aging at 136℃ is 92%, and the retention rate of elongation at break is 94%, ...

Embodiment 2

[0061] Example 2: Using SEBS-G1650 instead of SEBS-G1654, N250 white oil-filled oil and PP-R370Y form the base material, and the composition of other components is equivalent to that of Example 1. From the test results of Example 2 in Table 4, it can be found that compared with Example 1, the tensile strength of the prepared flame-retardant composite material and the extruded wire and the strength retention rate after aging are slightly reduced, but they are still far Higher than the lower limit of the UL standard, except that the melt index of the material is increased from 2.5g / 10min to 8.6g / 10min, other physical properties generally change little. In general, wires and materials have excellent comprehensive performance, which meets the requirements of charging wires for electric vehicles. At the same time, compared with Example 1, the fluidity of the material in Example 2 is increased, making it easier to extrude wires with thinner walls.

Embodiment 3

[0062] Example 3: Using SEBS-G1650 instead of 50% of the added amount of SEBS-G1654, oil-extended white oil N250 and PP-R370Y form a TPE-S substrate, and the other components are equivalent to those of Example 1 and Example 2. composition. From the test results of Example 3 in Table 4, it can be found that the properties of the prepared flame-retardant composite material and the extruded wire are between the physical properties of Example 1 and Example 2, and the overall performance is good, which fully meets the requirements of charging wires for electric vehicles. Requirements.

[0063] Comparative Example C-1: On the basis of Example 3, keeping the total amount of hexaphenoxycyclotriphosphazene and MDH H7C / 2 added, only changing the addition ratio of the two flame retardants (from the original 1:1 to 2:1), other components and ratios remain unchanged. From the test results of Comparative Example C-1 in Table 5, it can be found that the flame-retardant properties of the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com