Aqueous coating material with ultralow VOC (Volatile Organic Compound) release and preparation method thereof

A water-based coating, ultra-low technology, applied in the direction of coating, etc., can solve the problems of long film formation time, inconvenient construction, limited application and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Preparation of copolymer emulsion A

[0030] 212.9 g methyl methacrylate, 227.4 g butyl acrylate, 4.8 g methacrylic acid, 9.6 g methacrylamide, 14.4 g diacetone acrylamide and 9.6 g 3-(methacryloxy)propylmethyl Dimethoxysilane, 0.72g EF-810, 0.56g DSB, 0.25g PE-6100, 0.5g NaHCO 3 and 327.6g of deionized water were sequentially added into a 2L reaction kettle with a stirring device, and the stirring was started to pre-emulsify and disperse for 1 hour.

[0031] Add 6.48g EF-810, 5.04g DSB, 2.27gPE-6100, 0.5g NaHCO in sequence to a 2L reactor equipped with a stirring device 3 , 218.4g deionized water, 11.2g methyl methacrylate, 11.97g butyl acrylate, 0.3g methacrylic acid, 0.5g methacrylamide, 0.8g diacetone acrylamide, 0.5g3-(methacryloyloxy Base) propylmethyldimethoxysilane, start stirring and pass nitrogen gas for 30min, heat in water bath to 80°C, add 10g aqueous solution containing 0.25g ammonium persulfate, 10g aqueous solution containing 0.25g sodium bisulfite...

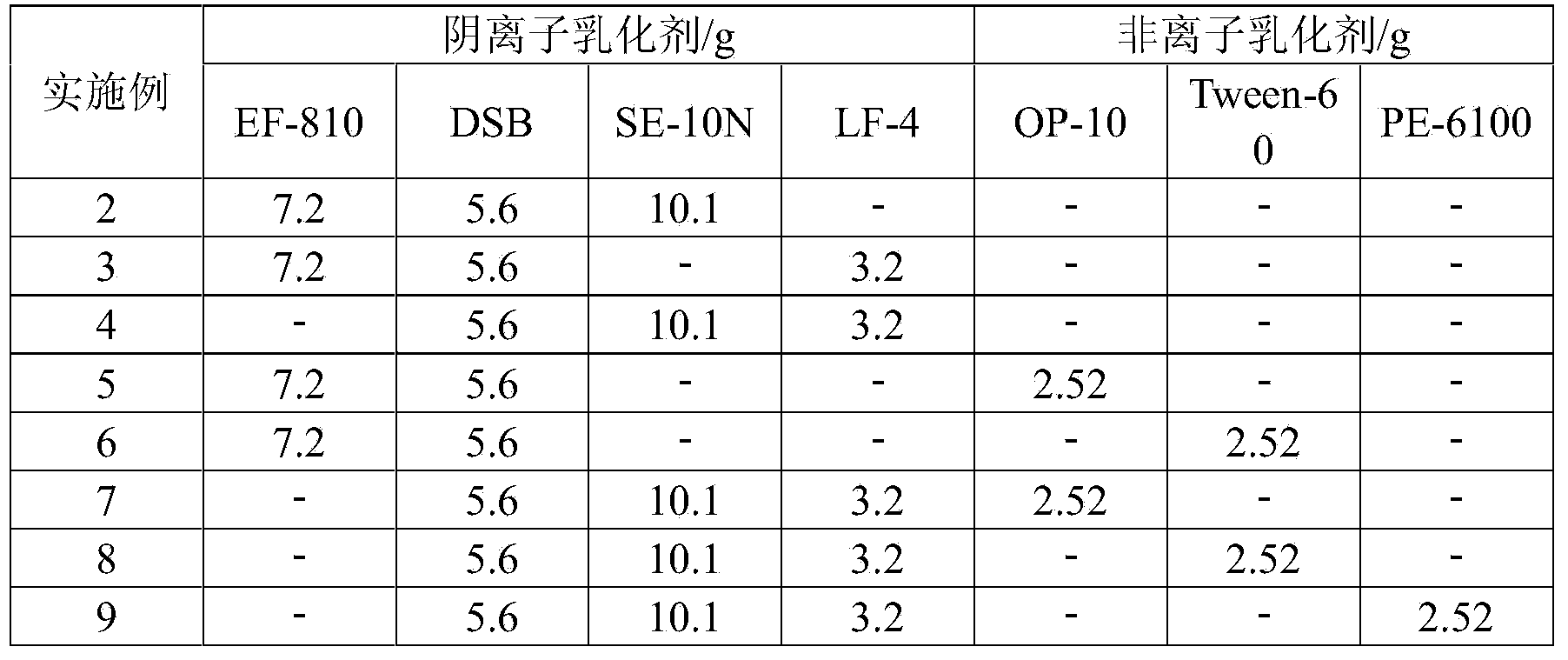

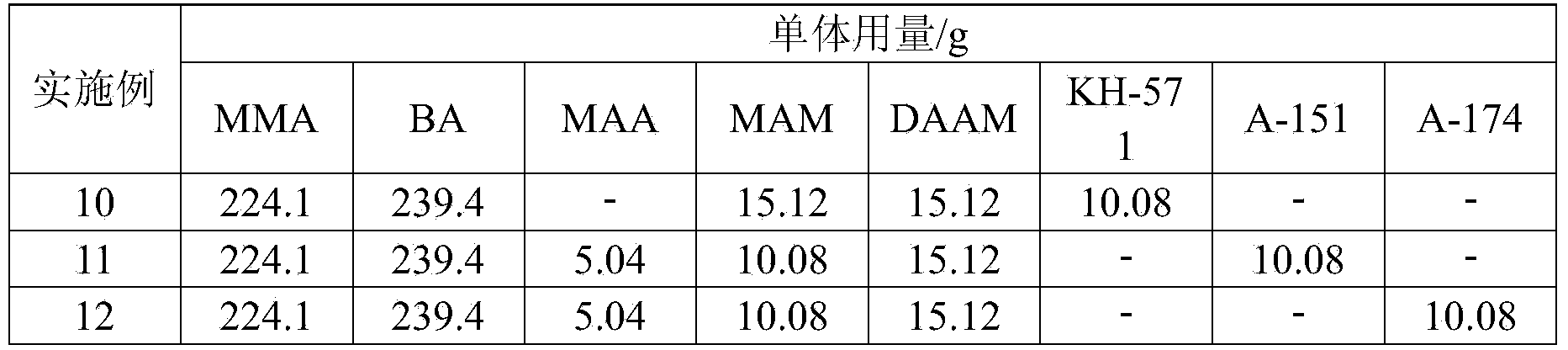

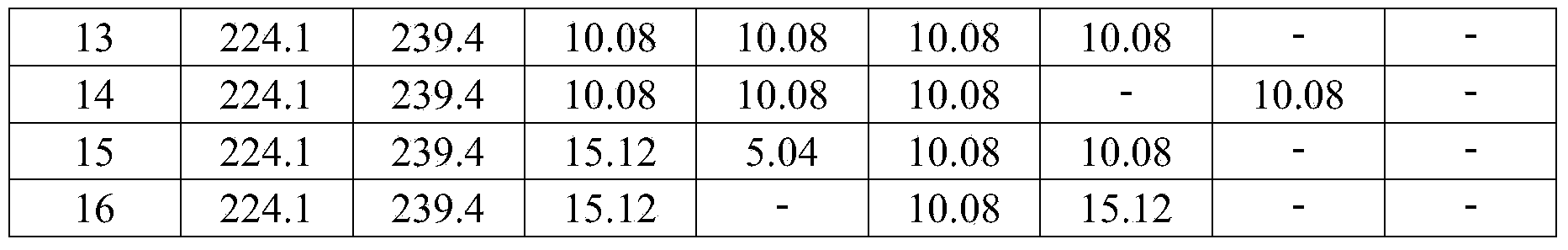

Embodiment 10-16B

[0048] Embodiment 10-16B emulsion synthesis used monomer proportioning

[0049]

[0050] In the table, MMA is methyl methacrylate, BA is butyl acrylate, MAA is methacrylic acid, AA is acrylic acid, MAM is methacrylamide, AM is acrylamide, DAAM is diacetone acrylamide, KH-571 is 3 -(methacryloxy)propylmethyldimethoxysilane, A-151 is vinyltriethoxysilane, A-174 is γ-(methacryloxy)propyltrimethoxy silane.

[0051] The difference between the A and B emulsions described in Examples 17-22 and Example 1 is that the distribution ratio of the emulsifier in the seed emulsion and the pre-emulsion is different, and other conditions and processes are consistent with Example 1, wherein the distribution ratio of the emulsifier is shown in table 3.

[0052] Table 3: The distribution ratio of emulsifier used in the synthesis of embodiment 17-22A and B emulsion

[0053] unit g

[0054]

[0055] Table 4: Test results of various performance indicators of the copolymer emulsion of Exampl...

Embodiment 34-38

[0063] Embodiment 34-38: Preparation of water-based wood white primer

[0064] Add 17g of water and 7.5g of wetting and dispersing agent BYK-190 into a 200ml beaker, stir for 10 minutes at a stirring speed of 1200rpm, add 75g of rutile titanium dioxide and 0.5g of anti-settling agent BYK-420, and disperse at a stirring speed of 2000rpm, Stop stirring when the fineness measured by a scraper fineness meter reaches below 30 μm, and the prepared white pulp is reserved for use.

[0065] Add 60g of polymer emulsion A and 20g of polymer emulsion B into a 500ml beaker, start stirring at 1600rpm for 10 minutes, then add 0.5g of defoamer BYK-024, 0.6g of defoamer TEGO-902W, and 0.2g of leveling agent BYK -346, 1.0g deionized water, increase the speed to 3000rpm and disperse for 30 minutes, add 1.0g of silica matting powder and disperse for 30 minutes at 3000rpm, reduce the speed to 1600rpm, add 5.0g deionized water, 2.0g wax in turn Auxiliary MD2000, 0.1g leveling agent BYK-333 were st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com