High temperature resistant polyimide wire enamel and preparation method thereof

A technology of polyimide paint and enameled wire paint, applied in the direction of coating, etc., can solve the problems of reduced paint film toughness and poor paint film continuity performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Add 400.5 grams of dried 4,4'-diaminodiphenyl ether and 2055 grams of N,N-dimethylacetamide into the reaction kettle, stir and dissolve completely at room temperature, and add 480.0 grams of dried homogeneous Pyrylenetetracarboxylic dianhydride was stirred and reacted for 2 hours, and the polymerization temperature was -5 to 20°C to obtain a wine red transparent and viscous polyamic acid solution with a solid content of 30%.

[0053] 388.4 grams of dimethyl terephthalate, 1859.2 grams of hexamethylenediamine and 1000 grams of hexamethylene are added to the reactor, a reflux device and a water separator are installed on the reactor, and cyclohexane is added in the water separator, and the temperature rises and stirs. reflow. When the amount of methanol no longer increases, the reaction is terminated. The product was washed with water and methanol, and dried to obtain chain-extended diamine.

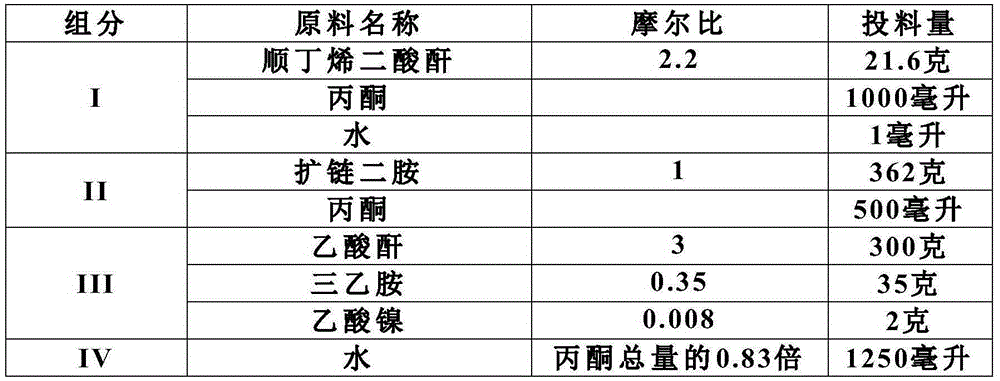

[0054] Chain-extending bismaleimide was prepared by chain-extending diamine a...

Embodiment 2

[0058] Add 496.6 grams of dried 4,4'-diaminodiphenyl sulfone and 2751 grams of N,N-dimethylacetamide into the reaction kettle, stir and dissolve completely at room temperature, and add 682.4 grams of dried 2 , 3,3',4'-diphenyl ether tetracarboxylic dianhydride, stirred for 2 hours, and the polymerization temperature was -5 to 20°C to obtain a wine red transparent and viscous polyamic acid solution with a solid content of 30%.

[0059] Add 194.2 grams of dimethyl terephthalate, 1188 grams of 4,4'-diaminodiphenylmethane and 1000 g of cyclohexane into the reaction kettle, install a reflux device and a water separator on the reaction kettle, and fill the water separator Cyclohexane, heated and stirred, refluxed. When the amount of methanol no longer increases, the reaction is terminated. The product was washed with water and methanol, and dried to obtain chain-extended diamine.

[0060] Chain-extending bismaleimide was prepared by chain-extending diamine and maleic anhydride thr...

Embodiment 3

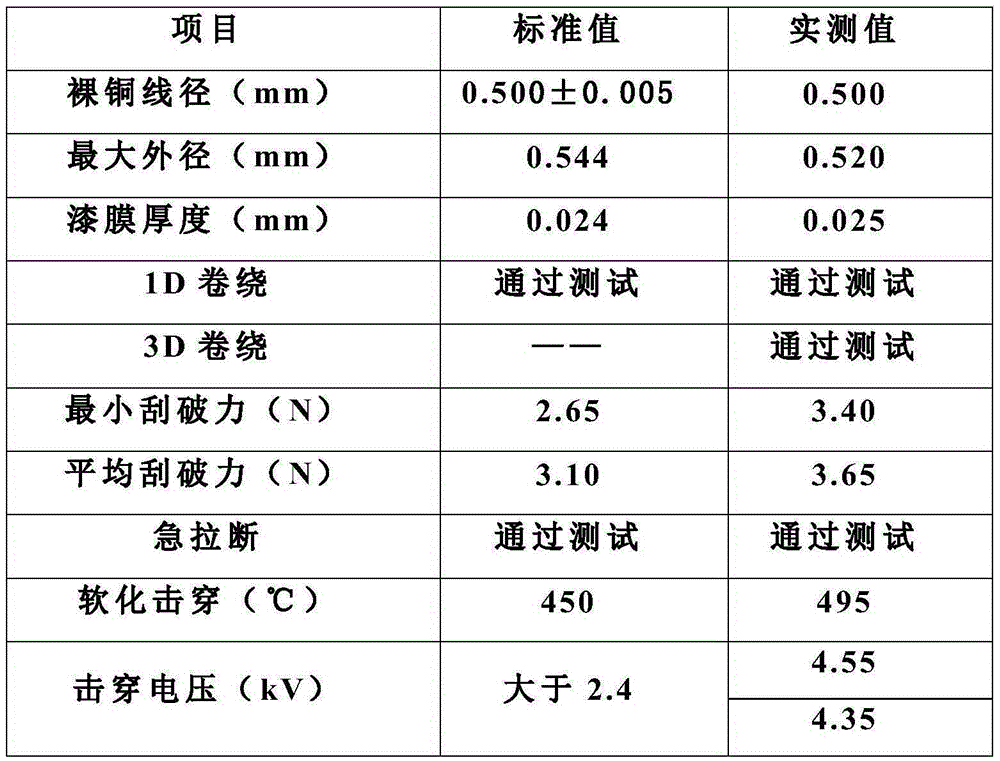

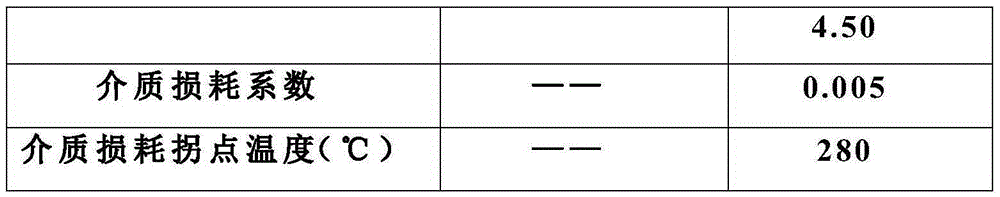

[0064] Investigation on the Properties of Polyimide Wire Enamel

[0065]With the "XND-1 Tu-4" viscometer produced by Wuhan Glamor Testing Equipment Co., Ltd., according to the test method specified in the national standard "GB / T1723 Paint Viscosity Measurement Method", test the above-mentioned Example 1 and Example 2. The obtained polyimide wire enamel has a viscosity value of 40 seconds and 35 seconds respectively.

[0066] Copper round wires with a nominal diameter of 0.5 mm are used to coat enameled wires on a horizontal enamelling machine. Turn on the circulation fan, the wind speed of the circulation fan is 2800RPM, the length of the oven is 3.50m, the furnace temperature rises to 400°C, and the wires are laid out, and the enamelling machine is continuously annealed and softened. The specification of the felt is 40mm×12mm in width×thickness, and the felt is flatly clamped on both sides of the wire with a felt splint. The distance between the felt and the paint tank is 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com