Method for producing DHA through fermentation

A fermentation medium and by-product technology, applied in the field of fermentation and production of DHA, can solve problems such as poor oxidation stability, achieve the effects of improving production efficiency, facilitating growth and product accumulation, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

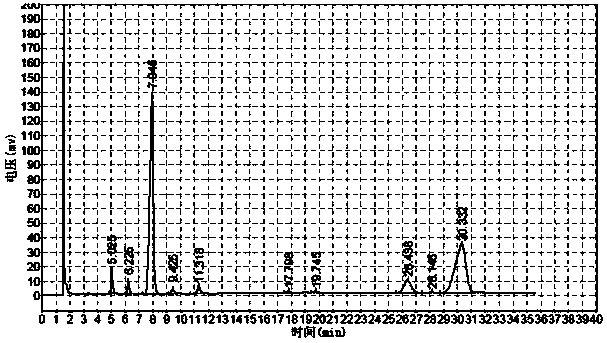

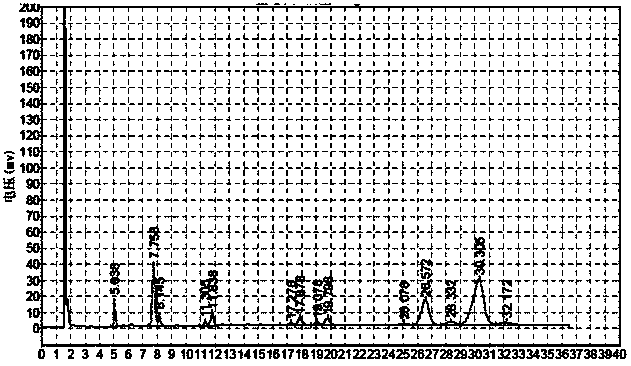

Image

Examples

Embodiment 1

[0033] This embodiment relates to a method for producing DHA by fermentation, comprising the steps of:

[0034] Step 1, preparing seed culture medium;

[0035] The components of the seed medium are, in every 1L medium, glucose 50.0g, yeast extract 5.0g, peptone 3.0g, MgSO 4 2.0g, KH 2 PO 4 2.0g, the balance is water; pH is 6.0, sterilized at 121°C for 30min;

[0036] Step 2, preparing fermentation medium;

[0037] (a) Glucose 100.0g / L, yeast extract powder 15.0g / L, chlorophyll 1g / L, VB 1 0.1g / L, VB 12 0.1g / L, VB 6 0.1g / L, MSG 8g / L, glutamic acid 4g / L, biotin 0.1g / L, β-carotene 0.1g / L, MgSO 4 1.0g / L, KH 2 PO 4 3.0g / L, Na 2 SO 4 12.0g / L, sea crystal 15g / L, the balance is water, and the pH is controlled at 5.5-6.5 during the fermentation process.

[0038] (b) Corn processing by-products 120g / L, glucose 20g / L, yeast extract 5g / L, MgSO 4 1.0g / L, KH 2 PO 4 3.0g / L, Na 2 SO 4 12.0g / L, sea crystal 15g / L, the balance is water, and the pH is natural during the fermentation...

Embodiment 2

[0049] This embodiment relates to a method for producing DHA by fermentation, comprising the steps of:

[0050] Step 1, preparing seed culture medium;

[0051] The components of the seed medium are, in every 1L medium, glucose 50.0g, yeast extract 5.0g, peptone 3.0g, MgSO 4 2.0g, KH 2 PO 4 2.0g, the balance is water; pH is 6.0, sterilized at 121°C for 30min;

[0052] Step 2, preparing fermentation medium;

[0053] The components of the fermentation medium are as follows: every 1L medium contains 120g of corn processing by-products, 20.0g of glucose, 10.0g of yeast extract, MgSO 4 1.0g, KH 2 PO 4 3.0g, Na 2 SO 4 12.0g, sea crystal 15g, the balance is water; sterilize at 121°C for 30min, cool down for later use;

[0054] Step 3, shake flask seed cultivation and seed expansion cultivation;

[0055] Take a glycerol tube of 1 mL of Schizochytrium sp. frozen in a refrigerator at -80 °C, inoculate it into a 500 mL Erlenmeyer flask containing 200 mL of the above seed medium,...

Embodiment 3

[0061] This embodiment relates to a method for producing DHA by fermentation, comprising the steps of:

[0062] Step 1, preparing seed culture medium;

[0063] The components of the seed medium are, in every 1L medium, glucose 40.0g, yeast extract 4.0g, peptone 2.0g, MgSO 4 1.0g, KH 2 PO 4 1.0g, the balance is water; pH is 6.0, sterilized at 121°C for 30min;

[0064] Step 2, preparing fermentation medium;

[0065] The components of the fermentation medium are as follows: every 1L medium contains 80g of corn processing by-products, 10.0g of glucose, 5.0g of yeast extract, MgSO 4 0.5g, KH 2 PO 4 2.0g, Na 2 SO 4 5.0g, sea crystal 5g, the balance is water; sterilize at 121°C for 30min, cool for later use;

[0066] Step 3, shake flask seed cultivation and seed expansion cultivation;

[0067] Take a glycerol tube of 1 mL of Schizochytrium sp. frozen in a refrigerator at -80 °C, inoculate it into a 500 mL Erlenmeyer flask containing 200 mL of the above seed medium, and cult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com