Large-size gradient-aluminum-content iron-chromium-aluminum ODS (oxide dispersion strengthened) alloy sheet material, and preparation method and application thereof

A technology of sheet material and aluminum content, applied in metal material coating process, chemical instruments and methods, metal layered products, etc. The effect of good oxidation resistance, simple process and low process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

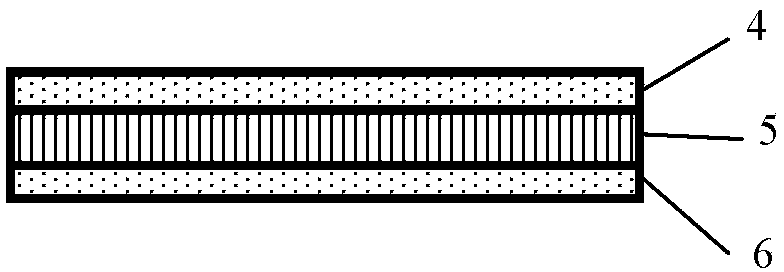

[0023] Specific Embodiment 1: In this embodiment, the large-size gradient aluminum content iron-chromium-aluminum ODS alloy thin plate material has a thickness of 10-300um and a diameter of 1000mm, and the content of one side of the thin plate is 15.0%-40.0%Cr, 10.0%-30.0% by weight. %Al, 0.3%-0.6%Y 2 o 3 And the composition of the balance amount of Fe, the other side is composed of 15.0%-40.0%Cr, 0%-5.0%Al, 0.3%-0.6%Y by weight 2 o 3 And the composition of Fe in balance.

specific Embodiment approach 2

[0024] Specific embodiment two: the preparation method of the large-scale gradient aluminum content iron-chromium-aluminum ODS alloy thin plate material described in specific embodiment one is carried out according to the following steps:

[0025] 1. Put the aluminum-containing ingot into a water-cooled copper crucible, place 35 grams of tungsten on the surface of the aluminum-containing ingot, put the yttrium oxide ceramic column or yttrium oxide powder into another water-cooled copper crucible, and place on the surface of the yttrium oxide ingot 10-15 grams of calcium fluoride, put the superalloy substrate on the substrate frame, wipe the surface with absolute ethanol, and evacuate to 1×10 -3 Pa-5×10 -3 Pa, then heat the superalloy substrate to 650-1000°C and keep it warm;

[0026] 2. Cover the superalloy substrate treated in step 1 with a baffle, increase the current of the two electron beams to 1.6-3A and 1.0-1.5A respectively, and stabilize it for 1-20min, open the baffl...

specific Embodiment approach 3

[0031] Specific embodiment three: the difference between this embodiment and specific embodiment two is that in step one, the vacuum is pumped to 3×10 -3 Pa. Others are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com