A kind of method for preparing CO2 oxidation ethylbenzene dehydrogenation catalyst by pyrolysis of nitrogen-containing compound

A nitrogen compound and ethylbenzene dehydrogenation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, hydrocarbons, etc., to achieve low synthesis temperature, good stability, and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

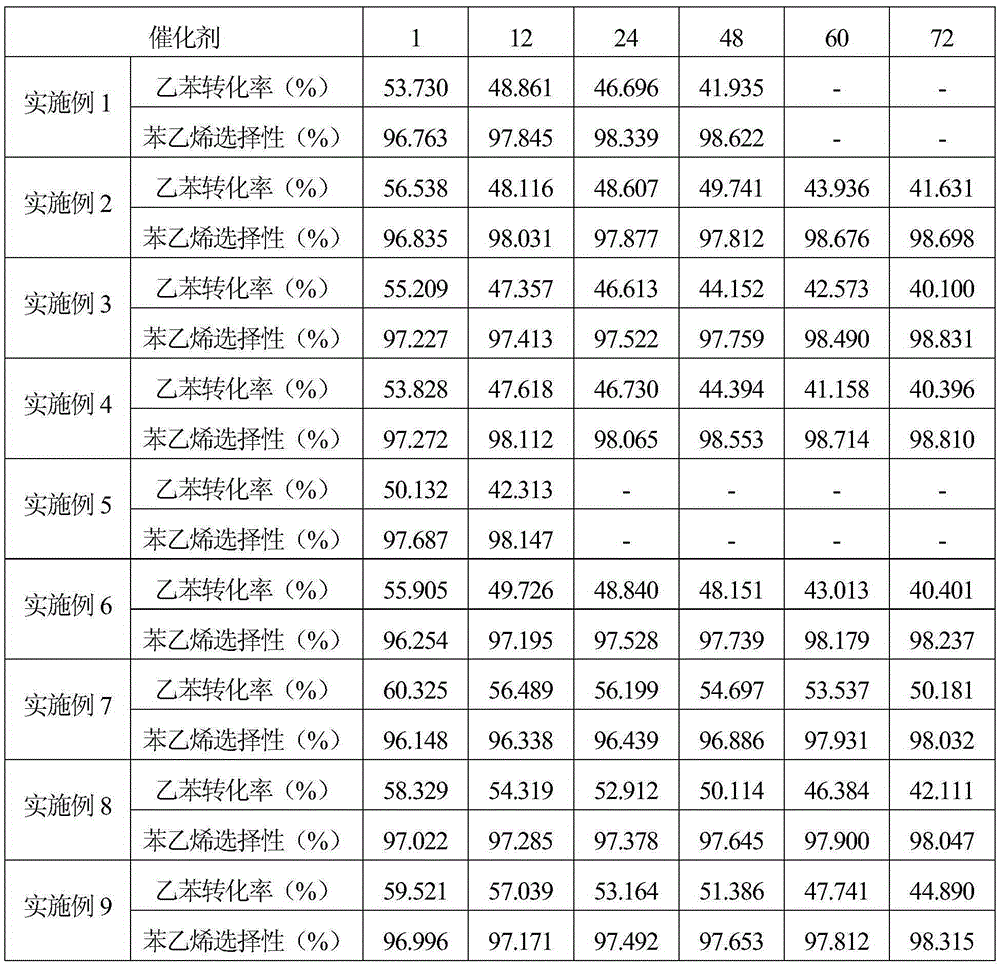

Examples

Embodiment 1

[0013] According to the composition of the catalyst is 6% V 2 o 5 -Al 2 o 3 , add 0.2302g of ammonium metavanadate and 20.6322g of aluminum nitrate nonahydrate into 100mL of 0.1% oxalic acid aqueous solution, stir until the solid is completely dissolved, add 12.5540g of ammonium carbonate, stir until evenly mixed, the nitrate in the resulting mixture The ratio of the molar amount of ammonium carbonate to the molar amount of ammonium carbonate is 1:0.5, the temperature is raised to 50°C, stirred at a constant temperature for 10 hours, and then heated to 200°C for 20 minutes, and then the temperature is raised to 550°C at a rate of 2°C / min. Calcined for 4 hours, naturally cooled to normal temperature, pressed into tablets, granulated, and passed through a 40-60 mesh sieve to prepare a catalyst.

Embodiment 2

[0015] In Example 1, the ammonium carbonate used was replaced with equimolar ammonium bicarbonate, and the other steps were the same as in Example 1 to prepare a catalyst.

Embodiment 3

[0017] In Example 1, the ammonium carbonate used was replaced with equimolar ammonium nitrate, and the other steps were the same as in Example 1 to prepare a catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com