Ceramic cbn grinding wheel for grinding the seat surface of the center hole of the fuel injection nozzle, its manufacturing method and a special mold in the manufacturing process

A manufacturing method and a technology for injecting nozzles, applied in the field of grinding wheels, can solve the problems of high mold size and assembly accuracy, high mold manufacturing cost, poor weight consistency, etc., and achieve stable and consistent grinding performance, improve organizational uniformity, and roughness. Strength boosting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Grinding wheel for center hole grinding, grinding wheel specification: 1A1W4×6×2×16.5×M2CBN325 / 400.

[0032] The production process is as follows:

[0033] 1) Mixing of grinding wheel molding materials: weigh according to the weight percentage of 20% vitrified bond, 63% cubic boron nitride abrasive, 5% single crystal corundum filler, 6% phenolic resin powder and 6% liquid paraffin wetting agent Each raw material. First, mix cubic boron nitride abrasive and single crystal corundum filler, then add liquid paraffin to wet the abrasive and filler, then add vitrified bond and mix evenly, and finally add phenolic resin powder and mix evenly.

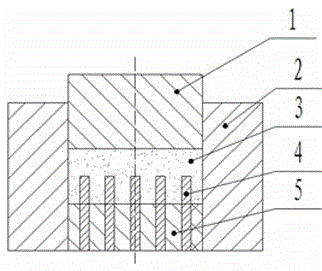

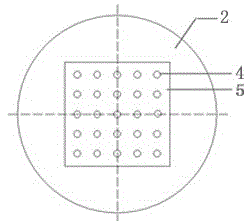

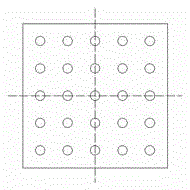

[0034] 2) Hot pressing molding: put the mixed molding material into a special mold, hot pressing molding on a hot pressing machine, hot pressing temperature is 180 ° C, pressure is 32 MPa, heat preservation and pressure holding for 1.5 hours, cooling and unloading the mold, and there are several pieces in the middle. Sand blocks for c...

Embodiment 2

[0041]Grinding wheel for seat surface grinding, grinding wheel specification: 1A1W3.3×10.5×2×21.6×M2CBN325 / 400.

[0042] The production process is as follows:

[0043] 1) Mixing of grinding wheel molding materials: weighed according to the weight percentage of 22% vitrified bond, 65% cubic boron nitride abrasive, 2% single crystal corundum filler, 5% phenolic resin powder and 6% liquid paraffin wetting agent Each raw material. First, mix cubic boron nitride abrasive and single crystal corundum filler, then add liquid paraffin to wet the abrasive and filler, then add vitrified bond and mix evenly, and finally add phenolic resin powder and mix evenly.

[0044] 2) Hot pressing molding: put the mixed molding material into a special mold, hot pressing molding on a hot pressing machine, the hot pressing temperature is 165 ° C, the pressure is 35 MPa, heat preservation and pressure holding for 1.2 hours, cooling and unloading the mold, and there are several pieces in the middle. A ...

Embodiment 3~6

[0051] Each raw material weight percentage of emery wheel described in table 3 embodiment 3~6

[0052]

[0053] Such as making the grinding wheel for center hole grinding, the manufacturing method of the grinding wheel described in Examples 3-6 in Table 3 can refer to Example 1. The special mold used in the making process is the same as embodiment 1. See Table 4 for the grinding effect of the grinding wheel described in Examples 3 to 6 in Table 3.

[0054] Table 4, the grinding effect of grinding wheel and domestic and foreign products of embodiment 3~6 middle hole grinding

[0055]

[0056] For making the grinding wheel for seat surface grinding, the manufacturing method of the grinding wheel described in Examples 3-6 in Table 3 can refer to Example 2. The special-purpose mold used in the production process is the same as embodiment 2. See Table 5 for the grinding effect of the seat surface of the emery wheel described in Examples 3 to 6 in Table 3.

[0057] Table 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com