Method for preparing mineral wool by using high-calcium coal ash

A high-calcium fly ash, mineral wool technology, applied in glass manufacturing equipment, manufacturing tools, glass production and other directions, can solve the problems of increasing the production cost of mineral wool, consuming large coke, harming the ecology, etc., and achieving high added value utilization. , protect the environment, and promote the effect of the economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

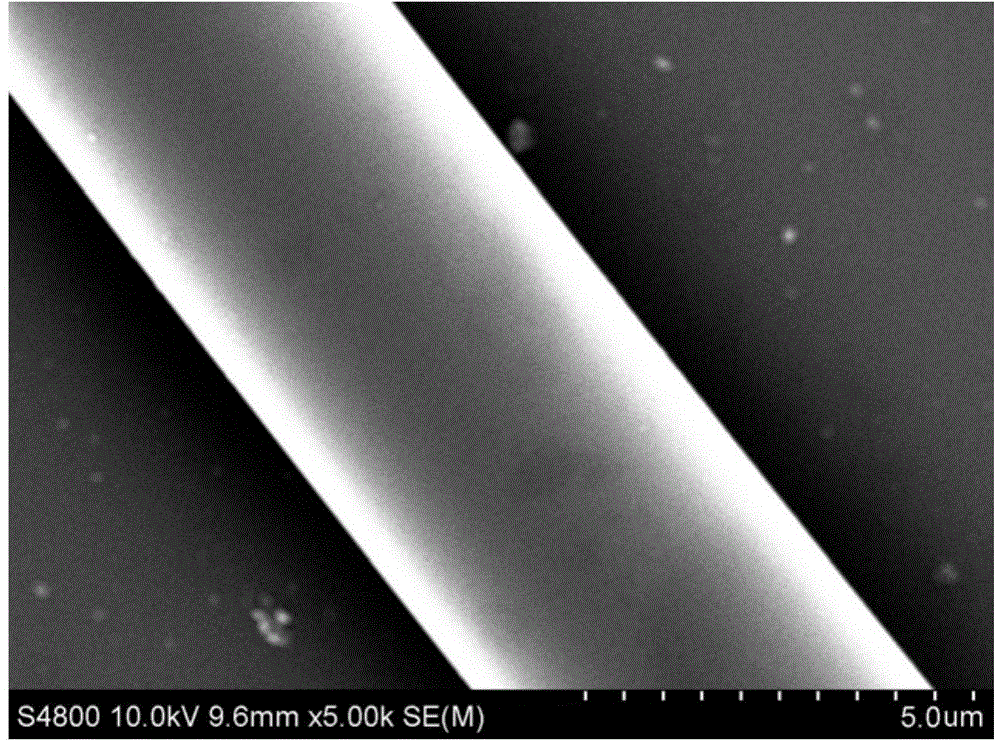

Embodiment 1

[0089] A. Ingredients

[0090] Weigh the following components (1)-(5) respectively:

[0091] (1) high calcium fly ash with CaO mass content of 10%;

[0092] (2) SiO 2 ;

[0093] (3)Al 2 o 3 ;

[0094] (4) MgO;

[0095] (5) CaO;

[0096] Proportion the above components, then mix them evenly and pulverize to obtain the ingredients, wherein the ratio of each component in the proportion should make the SiO in the final obtained mineral wool 2 The mass percentage is 38%, Al 2 o 3 The mass percentage content is 18%, the CaO mass percentage content is 26% and the MgO mass percentage content is 6%, and the others are impurity components.

[0097] B. Ball making

[0098] Add polyvinyl alcohol to the batching obtained in step A, wherein the quality of polyvinyl alcohol is 1% of the batching mass, and obtain pellets with a diameter of 3 cm after pelletizing.

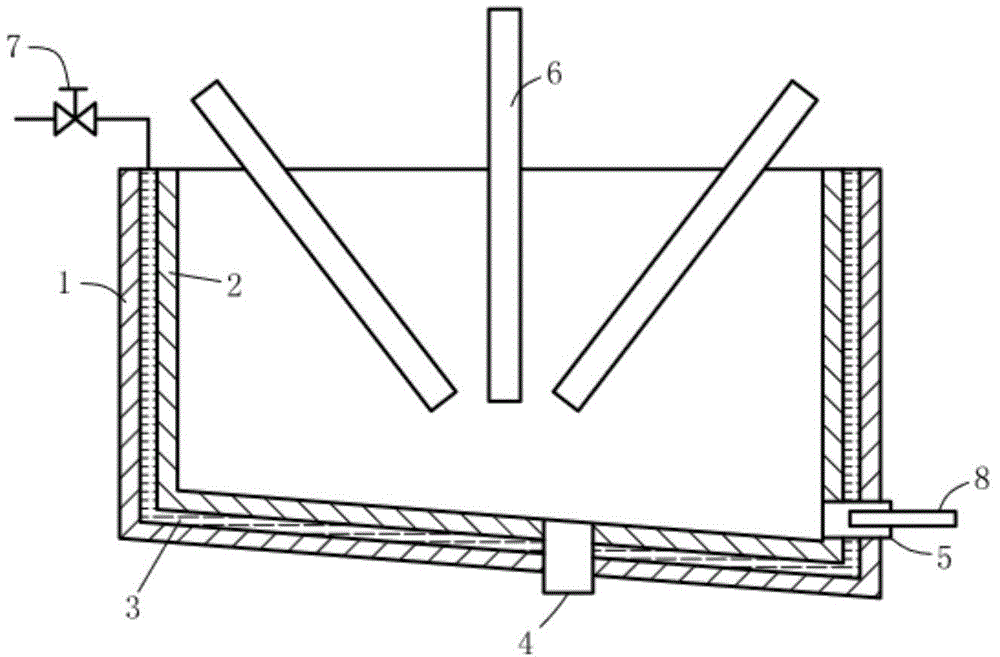

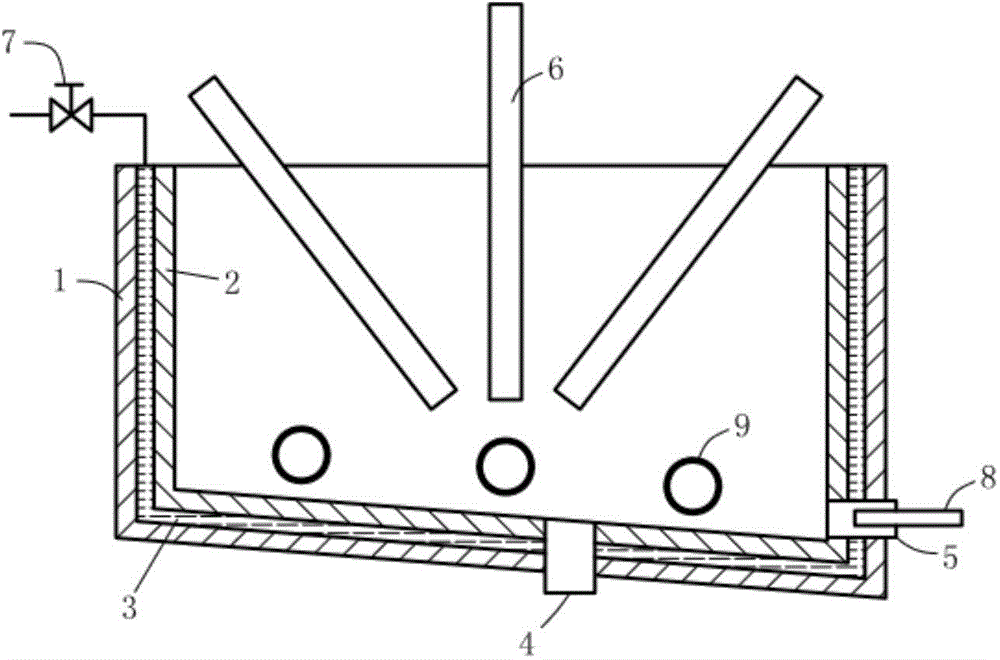

[0099] C. Melting, removing iron and carbon

[0100] Put the pellets into the above-mentioned iron and carbon removal ...

Embodiment 2

[0104] A. Ingredients

[0105] Weigh the following components (1)-(5) respectively:

[0106] (1) CaO mass content is 20% high calcium fly ash;

[0107] (2) SiO 2 ;

[0108] (3)Al 2 o 3 ;

[0109] (4) MgO;

[0110] (5) CaO;

[0111] Proportion the above components, then mix them evenly and pulverize to obtain the ingredients, wherein the ratio of each component in the proportion should make the SiO in the final obtained mineral wool 2 The mass percentage is 36%, Al 2 o 3 The mass percentage content is 26%, the CaO mass percentage content is 28% and the MgO mass percentage content is 4%, and the others are impurity components.

[0112] B. Ball making

[0113] Add polyvinyl alcohol to the batching obtained in step A, wherein the quality of polyvinyl alcohol is 3% of the batching mass, and obtain pellets with a diameter of 5 cm after pelletizing.

[0114] C. Melting, removing iron and carbon

[0115] Put the pellets into the above-mentioned iron and carbon removal dev...

Embodiment 3

[0119] A. Ingredients

[0120] Weigh the following components (1)-(5) respectively:

[0121] (1) high calcium fly ash with CaO mass content of 30%;

[0122] (2) SiO 2 ;

[0123] (3)Al 2 o 3 ;

[0124] (4) MgO;

[0125] (5) CaO;

[0126] Proportion the above components, then mix them evenly and pulverize to obtain the ingredients, wherein the ratio of each component in the proportion should make the SiO in the final obtained mineral wool 2 The mass percentage is 42%, Al 2 o 3 The mass percentage content is 18%, the CaO mass percentage content is 30% and the MgO mass percentage content is 3%, and the others are impurity components.

[0127] B. Ball making

[0128] Add polyvinyl alcohol to the batching obtained in step A, wherein the quality of polyvinyl alcohol is 5% of the batching mass, and obtain pellets with a diameter of 6 cm after pelletizing.

[0129] C. Melting, removing iron and carbon

[0130] Put the pellets into the above-mentioned iron and carbon remova...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com