A kind of preparation method of bis-carbamic acid alkyl ester type oil coagulant

A technology of bis-carbamic acid alkyl ester and oil condensing agent, which is applied in the field of preparation of TDI-derived bis-carbamic acid alkyl ester oil condensing agent, can solve the problems of incomplete oil condensing, high cost and large amount of oil, and achieves Good condensate effect, low cost and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

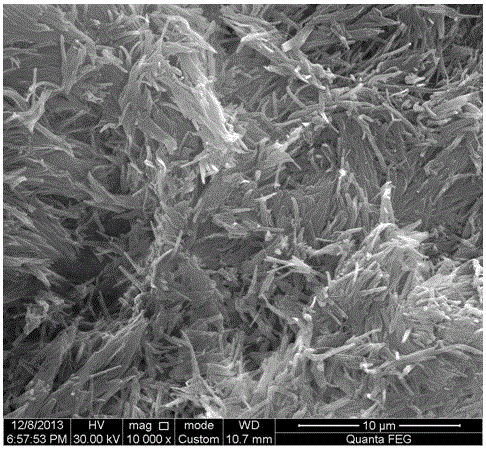

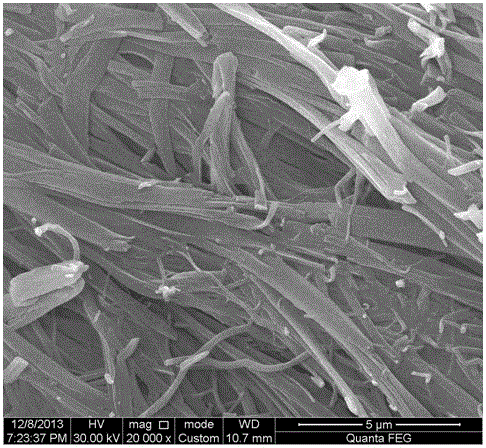

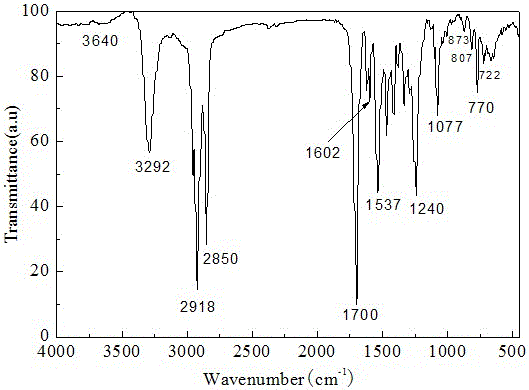

Image

Examples

specific Embodiment approach 1

[0030] Embodiment 1: In this embodiment, 12CTDI-derived alkyl biscarbamate oil gelling agent is prepared according to the following steps:

[0031] (1) Add 0.05 mol of TDI (2,4 / 2,6-toluene diisocyanate) and 0.10 mol of lauryl alcohol into 100 mL of chloroform, stir evenly, and transfer to a 250 mL three-necked flask.

[0032] (2) The mixture was continuously stirred and reacted in a water bath at 55° C. for 24 hours;

[0033] (3) After the reaction is finished, the temperature is raised to 85° C., and the solvent chloroform is distilled off by atmospheric distillation to obtain a concentrated solution;

[0034] (4) Pour the concentrated solution into a glass plate with d=9.5cm while it is hot, and place it in a vacuum drying oven at 138°C for 8 hours to remove unreacted TDI and improve the purity of the gelling agent.

[0035] (5) Take it out, cool it at room temperature into a white solid block, and pulverize it with a small universal pulverizer for 30 seconds to obtain a 12...

specific Embodiment approach 2

[0037] Specific embodiment two: In this embodiment, 14CTDI-derived alkyl biscarbamate oil gelling agent is prepared according to the following steps:

[0038] (1) Add 0.05mol (actually a little excess) of TDI (2,4 / 2,6-toluene diisocyanate) and 0.10mol of 1-tetradecyl alcohol into 100mL of acetone, stir well, and transfer to 250mL in the three-neck flask.

[0039] (2) The mixture was continuously stirred and reacted in a water bath at 50° C. for 24 hours;

[0040] (3) After the reaction is finished, the temperature is raised to 75° C., and the solvent acetone is distilled off by atmospheric distillation to obtain a concentrated solution;

[0041] (4) Pour the concentrated solution into a glass plate with d=9.5cm while it is hot, and place it in a vacuum drying oven at 135° C. for 8 hours to remove unreacted TDI and improve the purity of the gelling agent.

[0042] (5) Take it out, cool it at room temperature into a white solid block, and pulverize it with a small universal pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com