Preparation method of coated modified nanometer titanium dioxide

A nano-titanium dioxide and modification technology, which is applied in the field of preparation of surface-coated modified nano-titanium dioxide, can solve the problems of poor dispersion and particle enlargement, and achieve the effects of improved dispersion, improved performance, and good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Weigh 25g of titanyl sulfate (TiOSO 4 ) was dissolved in 500ml deionized water to obtain a titanyl sulfate solution, and 12g of sodium hydroxide (NaOH) was dissolved in 200ml of deionized water to obtain a sodium hydroxide solution. Titanium solution to pH=7 to obtain nano-titanium dioxide precursor;

[0025] 2) Transfer the nano-titanium dioxide precursor to an autoclave, conduct a hydrothermal reaction at 160°C for 8 hours, then cool to room temperature, filter and wash to obtain a filter cake, which does not require drying;

[0026] 3) Redisperse 6g of the filter cake obtained in step 2) in 100ml of water, then add 0.24g of methyl acrylate, stir continuously at 70°C for 30min, then add 0.1g of potassium persulfate to react for 60min, then filter, wash, and drying to obtain polymethyl acrylate-coated and modified nano-titanium dioxide powder.

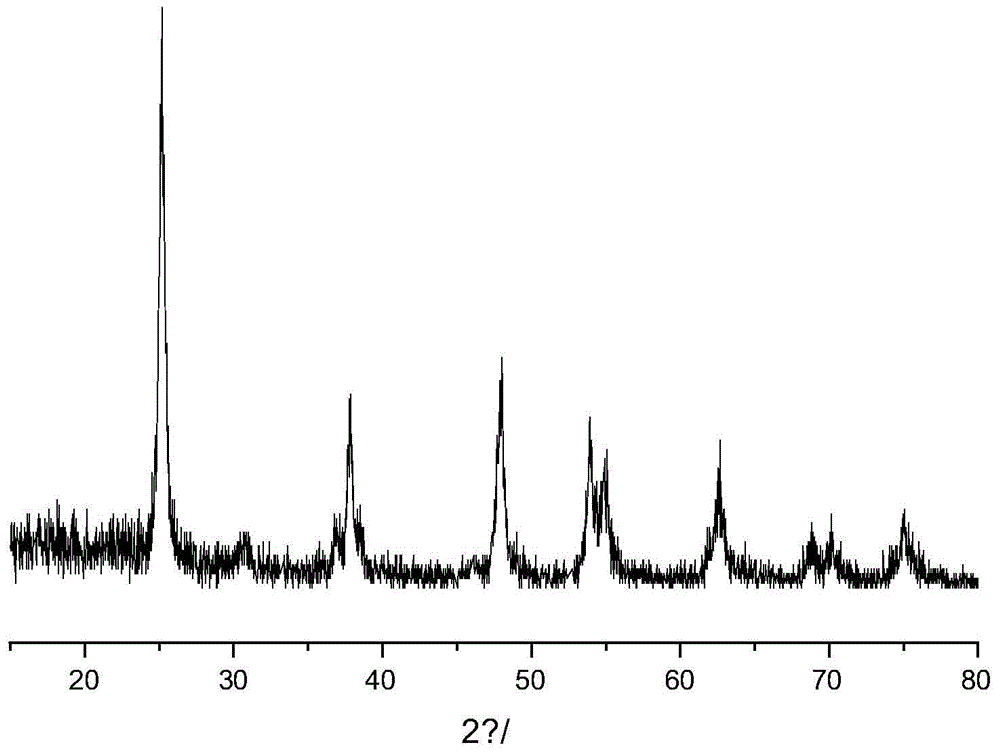

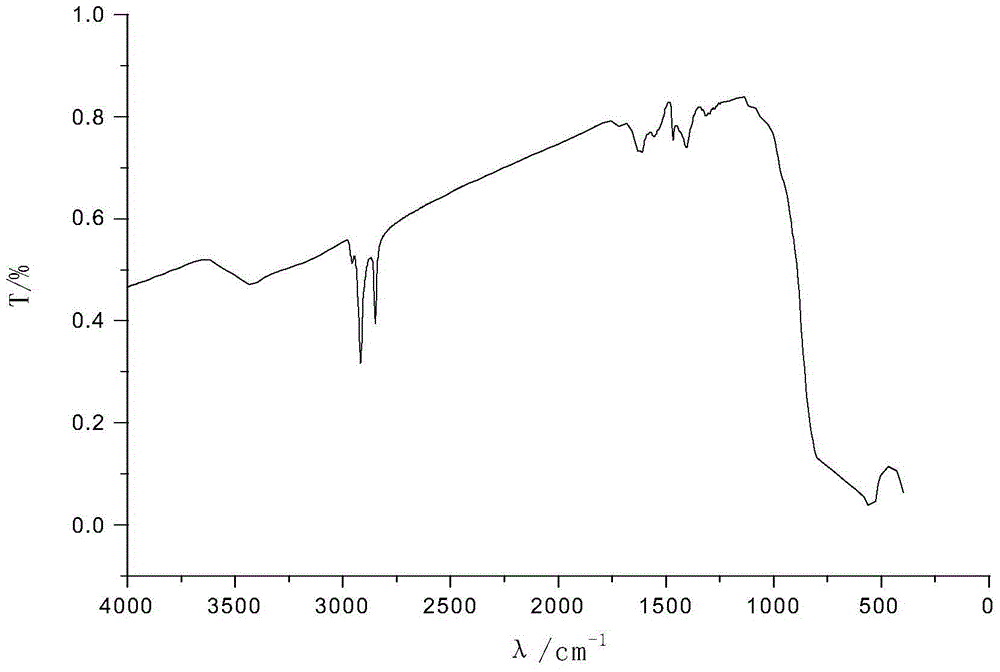

[0027] Compared with the sample obtained in Comparative Example 1, the X-ray diffraction pattern of the modified nano-ti...

Embodiment 2

[0029] 1) Weigh 5g of titanyl sulfate (TiOSO 4 ) was dissolved in 500ml deionized water to obtain a titanyl sulfate solution, and 4g of sodium hydroxide (NaOH) was dissolved in 200ml of deionized water to obtain a sodium hydroxide solution. Titanium solution to pH=7 to obtain nano-titanium dioxide precursor;

[0030] 2) Transfer the nano-titanium dioxide precursor to an autoclave, conduct a hydrothermal reaction at 200°C for 15 hours, then cool to room temperature, filter and wash to obtain a filter cake, which does not require drying;

[0031] 3) Redisperse 10 g of the filter cake obtained in step 2) in 120 ml of water, then add 0.6 g of ethyl acrylate, stir continuously at 80 ° C for 30 min, then add 0.2 g of sodium persulfate to react for 90 min, then filter, wash, Dry to obtain polyethyl acrylate-coated and modified nano-titanium dioxide powder.

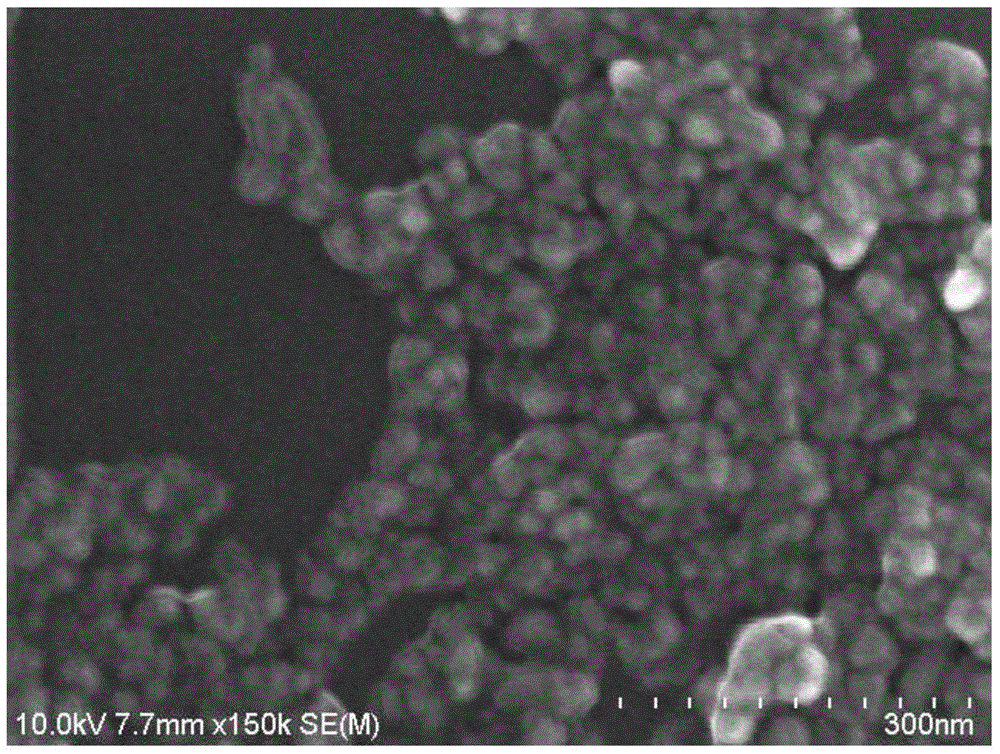

[0032] The X-ray diffraction analysis figure and the scanning electron microscope figure of the nano-titanium dioxide coated ...

Embodiment 3

[0034] 1) Weigh 25g of titanyl sulfate (TiOSO 4 ) was dissolved in 500ml deionized water to obtain a titanyl sulfate solution, and 12g of sodium hydroxide (NaOH) was dissolved in 200ml of deionized water to obtain a sodium hydroxide solution. Titanium solution to pH=7 to obtain nano-titanium dioxide precursor;

[0035] 2) Transfer the nano-titanium dioxide precursor to an autoclave, conduct a hydrothermal reaction at 230°C for 24 hours, then cool to room temperature, filter and wash to obtain a filter cake, which does not require drying;

[0036] 3) Redisperse 12g of the filter cake obtained in step 2) in 150ml of water, then add 0.36g of butyl acrylate, stir continuously at 90°C for 30min, then add 0.5g of ammonium persulfate to react for 120min, then filter, wash, and drying to obtain polybutyl acrylate-coated and modified nano-titanium dioxide powder.

[0037] The X-ray diffraction analysis figure of the nano-titanium dioxide coated and modified by polybutyl acrylate obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com