Copper complex based on dipyridine piperazine ligand and Anderson type polyacid, and synthetic method and application thereof

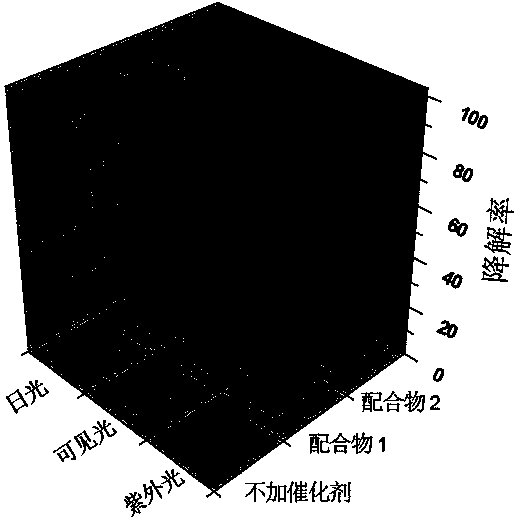

A technology of bispyridine piperazine and bispyridine bispiperazine, which is applied in the field of photocatalytic materials and synthesis, can solve the problems of inability to achieve effective catalytic degradation, limited application range, poor affinity, etc., and achieve good stability and symmetry , Increase hydrophilicity and prevent secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

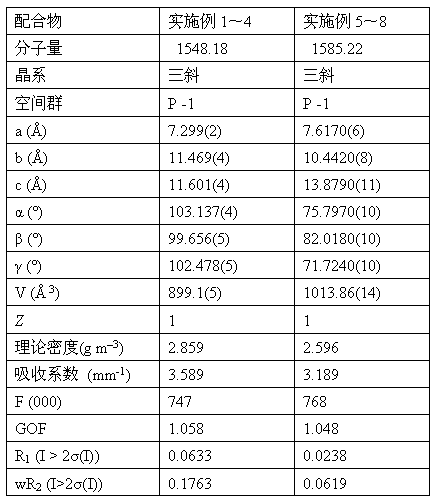

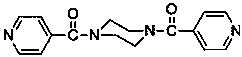

[0066] Example 1 Synthesis of H[Cu 2 L 1 Cr(OH) 6 Mo 6 o 18 (μ 2 -OH) 2 ]·4H 2 O, where L 1 for N , N '-bis(3-pyridineformyl)piperazine, the structural formula is:

[0067] 0.2mmol CuCl 2 2H 2 O, 0.10mmol N , N '-bis(3-pyridineformyl)piperazine, 0.10mmol Na 3 [CrMo 6 h 6 o 24 ]·8H 2 O and 7.0 mL H 2 O was sequentially added into a 25mL beaker, and stirred at room temperature for 20min to obtain a suspension mixture. After the pH of the suspension mixture was adjusted to 3.0 with 0.5mol / L HCl solution, it was transferred to a 25mL autoclave. The heating rate was increased to 120°C, and the temperature was kept for 24 hours under hydrothermal conditions, and the temperature was lowered to room temperature at a cooling rate of 5°C / h to obtain dark green blocky crystals, which were washed alternately with deionized water and ethanol for 4 times, and naturally dried at room temperature Dry, get H[Cu 2 L 1 Cr(OH) 6 Mo 6 o 18 (μ 2 -OH) 2 ]·4H 2 O, the pr...

Embodiment 2

[0068] Example 2 Synthesis of H[Cu 2 L 1 Cr(OH) 6 Mo 6 o 18 (μ 2 -OH) 2 ]·4H 2 O, where L 1 for N , N '-Bis(3-pyridinecarbonyl)piperazine

[0069] 0.4mmol Cu(NO 3 ) 2 ·3H 2 O, 0.15mmol N , N '-bis(3-pyridineformyl)piperazine, 0.20mmol Na 3 [CrMo 6 h 6 o 24 ]·8H 2 O and 11.0 mL H 2 O was sequentially added into a 25mL beaker, and stirred at room temperature for 10min to obtain a suspension mixture. After the pH of the suspension mixture was adjusted to 3.5 with 1.0mol / L HCl solution, it was transferred to a 25mL autoclave. The heating rate was increased to 110°C, and the temperature was kept for 72 hours under hydrothermal conditions, and the temperature was lowered to room temperature at a cooling rate of 5°C / h to obtain dark green blocky crystals, which were washed twice with deionized water and ethanol alternately, and naturally dried at room temperature Dry, get H[Cu 2 L 1 Cr(OH) 6 Mo 6 o 18 (μ 2 -OH) 2 ]·4H 2 O, the productive rate is 56%, and ...

Embodiment 3

[0070] Example 3 Synthesis of H[Cu 2L 1 Cr(OH) 6 Mo 6 o 18 (μ 2 -OH) 2 ]·4H 2 O, where L 1 for N , N '-Bis(3-pyridinecarbonyl)piperazine

[0071] 0.5mmol CuCl 2 2H 2 O, 0.10mmol N , N '-bis(3-pyridineformyl)piperazine, 0.30mmol Na 3 [CrMo 6 h 6 o 24 ]·8H 2 O and 15.0 mL H 2 O was sequentially added to a 25mL beaker, and stirred at room temperature for 30min to obtain a suspension mixture. After the pH of the suspension mixture was adjusted to 4.0 with 1.5mol / L HCl solution, it was transferred to a 25mL autoclave. The heating rate was increased to 120°C, and the temperature was kept for 96 hours under hydrothermal conditions, and the temperature was lowered to room temperature at a cooling rate of 2.5°C / h to obtain dark green blocky crystals, which were washed alternately with deionized water and ethanol for 3 times, and naturally dried at room temperature Dry, get H[Cu 2 L 1 Cr(OH) 6 Mo 6 o 18 (μ 2 -OH) 2 ]·4H 2 O, the productive rate is 64%, and it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| catalytic efficiency | aaaaa | aaaaa |

| catalytic efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com