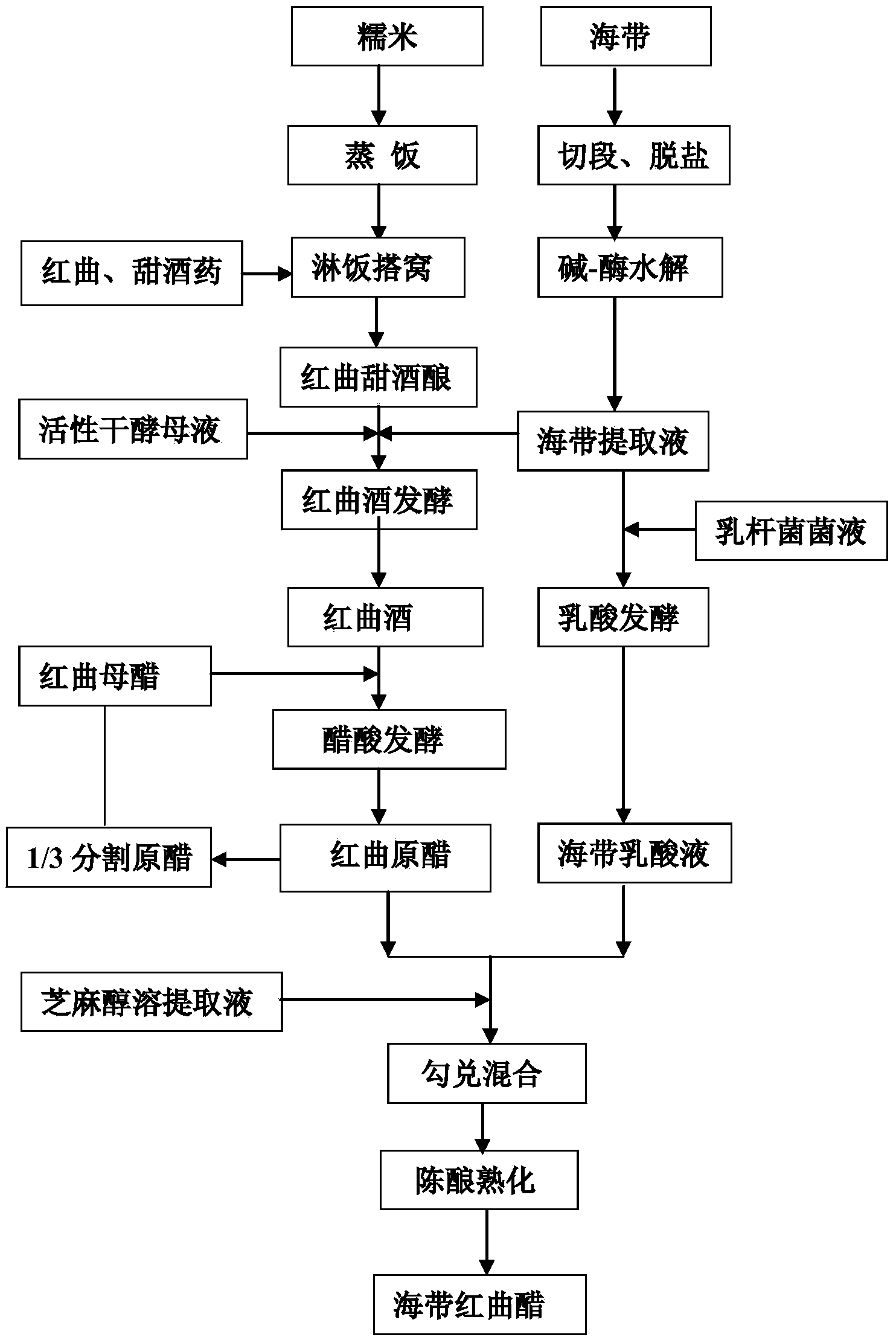

Preparation of kelp red rice vinegar

A technology of red yeast vinegar and kelp, which is applied in the field of food processing, and can solve the problems of extract components such as low yield and content of crude polysaccharides, destruction of polysaccharide activity, and small increase in yield of crude polysaccharides, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] (1) Preparation of kelp lactic acid solution:

[0042] (1) Kelp desalination: Soak the washed kelp in cold water for 120 minutes, and change the water 5 times during the soaking process.

[0043] (2) Alkali digestion: Drain the kelp after desalination, cut into kelp sections, add 1% NaCO 2 times the weight of kelp sections 3 The solution was boiled and digested for 1 hour to become pulpy kelp pulp.

[0044] (3) Enzymatic hydrolysis: use 28% acetic acid to adjust the pH of the kelp pulp to 4.5. Each component of compound enzyme is added step by step to carry out enzymatic hydrolysis, and the added amount of compound enzyme is 0.6% of the weight part of kelp pulp. The order of adding compound enzymes step by step was: add cellulase first, then add pectinase 10 minutes later, add xylanase and protease together after 10 minutes. The enzymatic hydrolysis temperature is 56°C. When the enzymatic hydrolysis time is about 60 minutes, measure the reducing sugar content of th...

Embodiment 2

[0058] (1) Preparation of kelp lactic acid solution:

[0059] (1) Kelp desalination: Soak the washed kelp in cold water for 120 minutes, and change the water 3 times during the soaking process.

[0060] (2) Alkali digestion: Drain the kelp after desalination, cut into kelp sections, add 1% NaCO 2 times the weight of kelp sections 3 The solution was boiled and digested for 1 hour to become pulpy kelp pulp.

[0061] (3) Enzymatic hydrolysis: use 28% acetic acid to adjust the pH of the kelp pulp to 4.5. Add the various components of compound enzyme gradually to carry out enzymatic hydrolysis. The amount of compound enzyme added is 0.6% of the weight of kelp pulp. The order of compound enzyme is gradually added: first add cellulase, then add pectinase for 10 minutes, and then add pectinase for 10 minutes. Then add xylanase and protease together. The enzymatic hydrolysis temperature is 53°C. The enzymatic hydrolysis time is about 60 minutes, and the reducing sugar content of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com