Novel high-service life die-casting mold steel and process method for manufacturing aluminum-magnesium die-casting mold

A technology of die-casting mold and process method, which is applied in the field of new high-life die-casting die steel and the manufacture of aluminum-magnesium die-casting dies, which can solve the problems of out-of-tolerance, large internal stress, poor corrosion resistance, etc., and achieve the advantages of increased service life and strong oxidation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

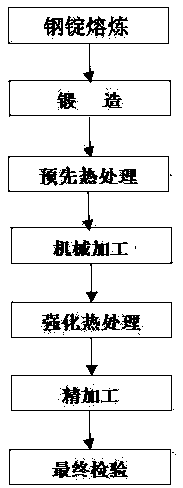

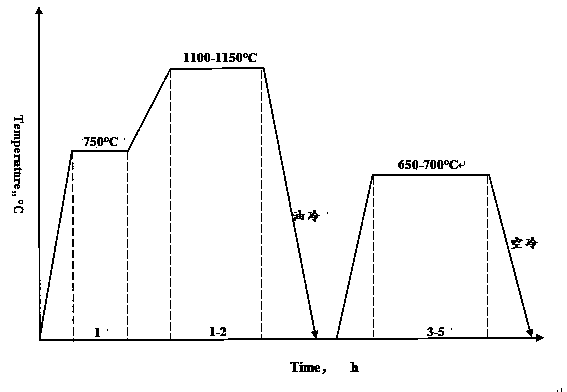

[0030] A method of manufacturing a new type of high-life die-casting mold, such as figure 1The following steps are shown: steel ingot smelting, forging, preheating, machining, intensified heat treatment, finishing and final inspection; the mass percentage contents of the alloying elements in the steel ingot are: 0.15%C, 12%Cr, 5%Mo , 9%Co, 0.35%V, 0.25%Nb, S figure 2 Shown: First heat the workpiece to 550°C-750°C for 1 hour to preheat and keep warm to reduce the hot and cold temperature of the mold during the heating process, so that the internal and external temperatures are uniform to reduce the deformation caused by thermal stress, and then under nitrogen protection Raise the temperature to 1150°C in the atmosphere and keep it for 1.5 hours to make the internal structure of the mold fully austenitized, and then oil quench and cool to room temperature to obtain the corresponding martensite and residual austenite to reduce the internal structure of the workpiece. Deformation...

Embodiment 2

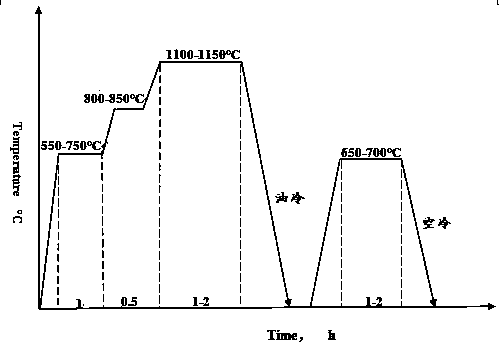

[0032] A method for manufacturing a new type of high-life die-casting mold. The content and process steps of the alloy elements used in this step are especially suitable for large-scale die-casting molds with complex shapes, such as figure 1 The following steps are shown: steel ingot smelting, forging, preheating, machining, intensified heat treatment, finishing and final inspection; the mass percentage contents of the alloying elements in the steel ingot are: 0.18%C, 14%Cr, 7%Mo , 11%Co, 0.35%V, 0.45%, S figure 2 Shown: First heat the workpiece to 550°C-750°C and keep it warm for 1 hour, then raise the temperature to 800°C-850°C and keep it warm for 0.5 hour. Thermal insulation treatment to reduce the temperature difference between hot and cold of the mold during the heating process, so that the internal and external temperatures are uniform to reduce the deformation caused by thermal stress; finally, the temperature is raised to 1150°C for austenitic heat preservation in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com