Method for enhancing property of ramie fiber through oxidative degumming

A technology of ramie fiber and oxidation degumming, which is applied in the field of improving fiber performance, to achieve the effects of good tensile performance, small dosage, and improved environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The method of improving the tensile properties of ramie fiber in oxidation degumming is as follows:

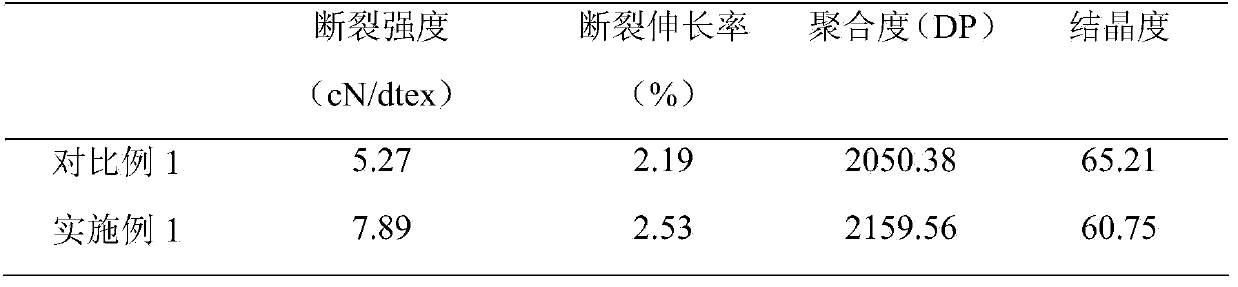

[0023] 4 kg of hydrogen peroxide (concentration is 30%), 0.6 kg of sodium hydroxide, 0.2 kg of anthraquinone, 0.4 kg of HEDP, 0.6 kg of acetanilide, 0.8 kg of sodium tripolyphosphate and 193.6 kg of water to form an oxidation degumming solution. 20 kg of raw hemp is immersed in 200 kg of solution. Raise the temperature to 85°C and keep it warm for 1 hour. Then add 1.4 kg of sodium hydroxide to the degumming solution, raise the temperature to 100° C., and keep the temperature for 1.5 hours. Take out the hemp and wash it with clean water. Use 1 kg of sodium bisulfite to prepare a reducing solution, immerse the treated ramie in it, raise the temperature to 70°C, and keep it warm for 40 minutes. The degummed ramie is pickled, then dehydrated, oiled, deoiled and dried. The breaking strength, elongation at break, and work at break of the fiber were tested by a tensile str...

Embodiment 2

[0029] The method of improving the tensile properties of ramie fiber in oxidation degumming is as follows:

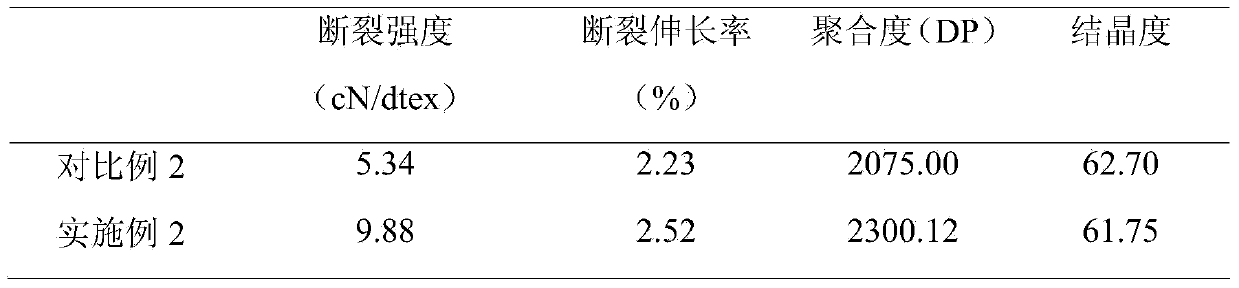

[0030] 4 kg of hydrogen peroxide (concentration is 30%), 0.6 kg of sodium hydroxide, 0.4 kg of anthraquinone, 0.4 kg of sodium polyacrylate, 0.6 kg of acetanilide, 0.8 kg of sodium pyropolyphosphate and 193.6 kg of water to form an oxidation degumming solution . 20 kg of raw hemp is immersed in 200 kg of solution. Raise the temperature to 85°C and keep it warm for 1 hour. Then add 1.4 kg of sodium hydroxide to the degumming solution, raise the temperature to 100° C., and keep the temperature for 1.5 hours. Take out the hemp and wash it with clean water. Use 1 kg of sodium bisulfite to prepare a reducing solution, immerse the treated ramie in it, raise the temperature to 70°C, and keep it warm for 40 minutes. The degummed ramie is pickled, then dehydrated, oiled, deoiled and dried. The breaking strength, elongation at break, and work at break of the fiber were teste...

Embodiment 3

[0036] The method of improving the tensile properties of ramie fiber in oxidation degumming is as follows:

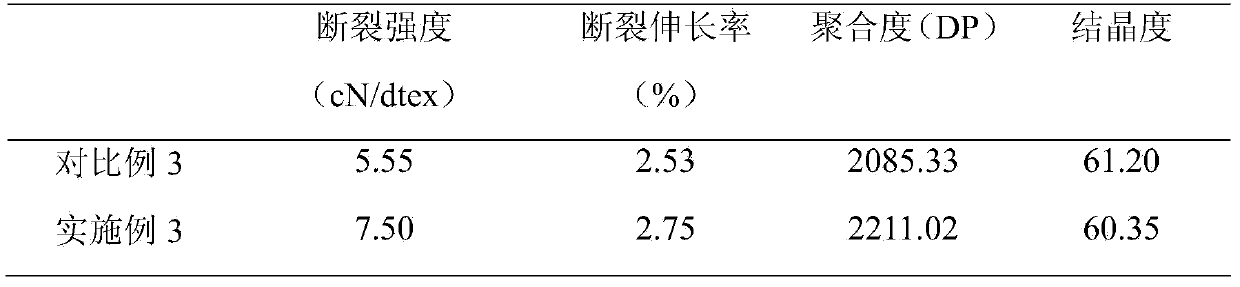

[0037] 1.2 kg of potassium peroxide, 0.6 kg of sodium hydroxide, 0.2 kg of sodium anthraquinone-2-sulfonate, 0.4 kg of sodium citrate, 0.6 kg of polyacrylamide, 0.8 kg of sodium pyropolyphosphate and 193.6 kg of water are made into oxidation degumming solution. 20 kg of raw hemp is immersed in 200 kg of solution. Raise the temperature to 85°C and keep it warm for 1 hour. Then add 1.4 kg of sodium hydroxide to the degumming solution, raise the temperature to 100° C., and keep the temperature for 1.5 hours. Take out the hemp and wash it with clean water. Use 1 kg of hydrosulfite to prepare a reducing solution, immerse the treated ramie in it, raise the temperature to 70°C, and keep it warm for 40 minutes. The degummed ramie is pickled, then dehydrated, oiled, deoiled and dried. The breaking strength, elongation at break, and work at break of the fiber were tested by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com